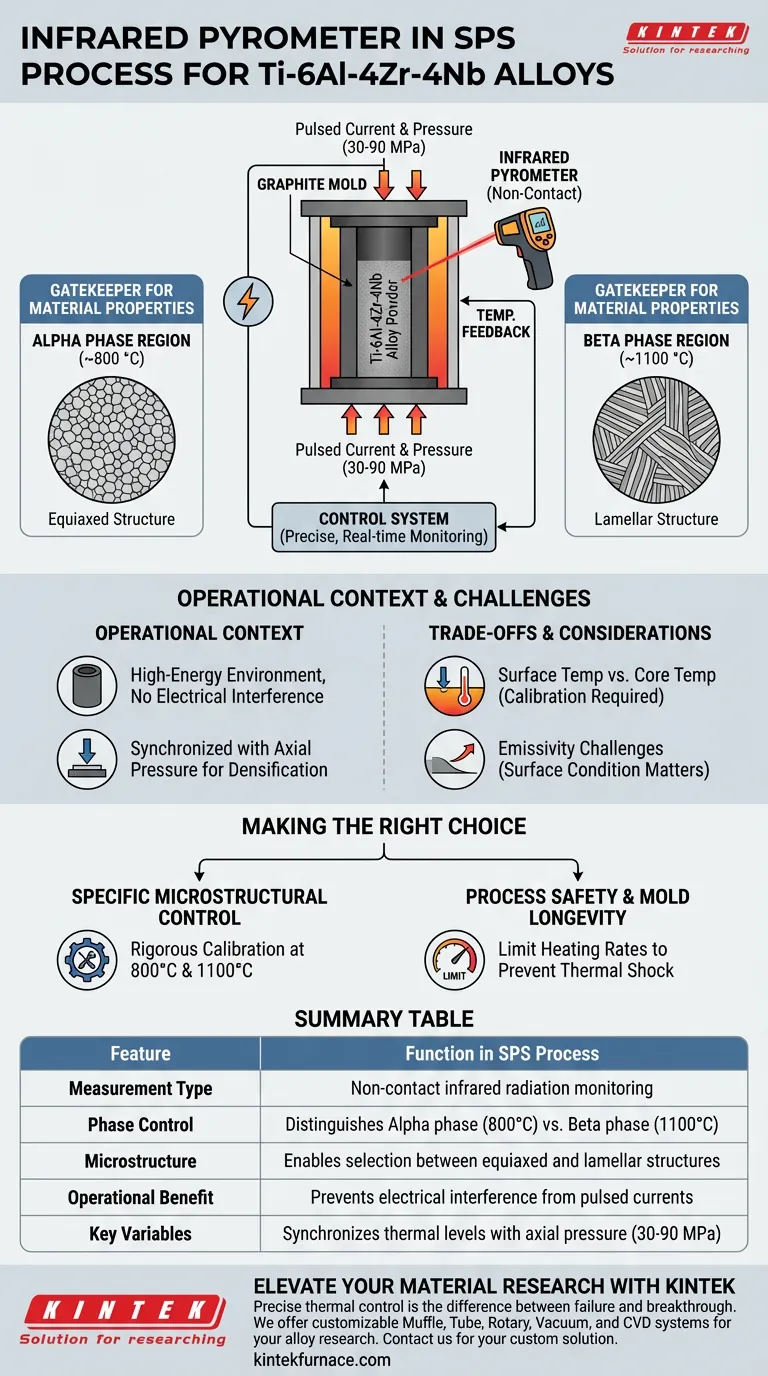

The primary function of an infrared pyrometer in the Spark Plasma Sintering (SPS) process is to provide precise, real-time, non-contact temperature monitoring. This device acts as the central feedback mechanism for the control system, allowing for the exact thermal regulation required to sinter Ti-6Al-4Zr-4Nb alloys successfully.

The pyrometer serves as the critical gatekeeper for material properties in Ti-6Al-4Zr-4Nb alloys. By distinguishing between the alpha phase region at 800 °C and the beta phase region at 1100 °C, it enables precise manipulation of the alloy’s final microstructure.

The Critical Role of Phase Control

Distinguishing Phase Regions

For Ti-6Al-4Zr-4Nb alloys, temperature is not just a variable; it is the defining factor of the material's state. The infrared pyrometer provides the data necessary to navigate distinct phase regions.

It specifically monitors the transition between the alpha phase region (around 800 °C) and the beta phase region (around 1100 °C). Without this accurate feedback, the operator is blind to the metallurgical changes occurring within the chamber.

Regulating Microstructure

The reading provided by the pyrometer directly influences the final physical structure of the alloy.

By holding the temperature at specific setpoints based on pyrometer feedback, engineers can dictate whether the final product exhibits equiaxed or lamellar structures. Reliable feedback is essential to ensure the process yields the specific mechanical properties required for the application.

Operational Context within SPS

Monitoring in a High-Energy Environment

The SPS process utilizes high-strength cylindrical graphite molds that serve as both the powder container and the heating element.

Because these molds conduct high pulsed currents to generate internal heating, standard contact sensors can be impractical or interfere with the electrical path. The infrared pyrometer overcomes this by measuring thermal radiation from a distance, ensuring no electrical interference.

Managing Densification

During sintering, the alloy powder undergoes axial pressures ranging from 30 MPa to 90 MPa to facilitate densification.

The pyrometer ensures that the heat applied matches the pressure curve. This synchronization promotes efficient atomic diffusion and ensures the graphite mold reaches the correct temperature to facilitate consolidation without overheating.

Understanding the Trade-offs

Surface vs. Core Temperature

It is important to acknowledge that an infrared pyrometer typically measures the surface temperature of the graphite mold or a specific blackbody hole, rather than the powder core directly.

While graphite has excellent thermal conductivity, there may be a slight thermal lag between the measured point and the alloy center. Calibration is required to ensure the "read" temperature correlates accurately with the actual sample temperature.

Emissivity Challenges

The accuracy of an infrared pyrometer depends on the emissivity setting of the target material.

If the surface condition of the graphite mold changes (e.g., degradation or oxidation), the emissivity may shift. This can lead to erroneous temperature readings if not monitored and corrected, potentially pushing the alloy into an unintended phase region.

Making the Right Choice for Your Goal

To maximize the effectiveness of the SPS process for Ti-6Al-4Zr-4Nb alloys, consider your specific objectives:

- If your primary focus is specific microstructural control: rigorous calibration of the pyrometer at the 800 °C and 1100 °C setpoints is mandatory to ensure precise alpha/beta phase selection.

- If your primary focus is process safety and mold longevity: use the pyrometer to strictly limit heating rates, preventing thermal shock to the graphite mold under high axial pressures.

Precise optical monitoring transforms temperature from a simple metric into a tool for microstructural engineering.

Summary Table:

| Feature | Function in SPS Process |

|---|---|

| Measurement Type | Non-contact infrared radiation monitoring |

| Phase Control | Distinguishes Alpha phase (800°C) vs. Beta phase (1100°C) |

| Microstructure | Enables selection between equiaxed and lamellar structures |

| Operational Benefit | Prevents electrical interference from pulsed currents |

| Key Variables | Synchronizes thermal levels with axial pressure (30-90 MPa) |

Elevate Your Material Research with KINTEK

Precise thermal control is the difference between a failed sample and a breakthrough. At KINTEK, we understand the intricacies of Spark Plasma Sintering and high-temperature metallurgy. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of your Ti-6Al-4Zr-4Nb alloy research.

Whether you need precise optical monitoring or robust high-temp lab furnaces, our engineering team is ready to support your unique needs. Contact us today to find your custom solution.

Visual Guide

References

- Shilong Liang, Yoko Yamabe‐Mitarai. Microstructure Evolution and Mechanical Properties of Ti–6Al–4Zr–4Nb Alloys Fabricated by Spark Plasma Sintering (SPS). DOI: 10.1007/s11661-024-07422-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What is the purpose of in-situ reaction/hot pressing for (Ti0.95Nb0.05)3SiC2 targets? Achieve High Density Coatings

- What is the primary role of mechanical pressure in Ti-Al vacuum hot pressing? Optimize Bonding and Density

- What are the technical advantages of using a Spark Plasma Sintering (SPS) system for Barium Titanate ceramics?

- How does the high vacuum environment affect Ti-Al bonding? Unlock High-Strength Metallurgical Bonding

- Why is 'final short-time pressing' important in vacuum hot pressing? Unlock Maximum Material Density

- How do you maintain a heat press machine? A Proactive Guide to Consistent Prints & Longevity

- How does the vacuum environment affect AlMgTi composite hot pressing? Unlock Superior Bonding & Density

- What role does a vacuum hot press furnace play in the densification of nanocomposites? Achieve Near-Theoretical Density