In short, maintaining a heat press involves a consistent routine of cleaning, lubrication, and calibration. The most critical tasks are keeping the upper and lower platens clean and protected, lubricating the machine's pivot points with high-temperature grease, and regularly verifying the platen's temperature for accuracy.

A heat press is a simple machine, but its performance depends entirely on consistency. Viewing maintenance not as a chore, but as a critical part of your quality control process, is the key to preventing failed prints, protecting your investment, and ensuring the machine's longevity.

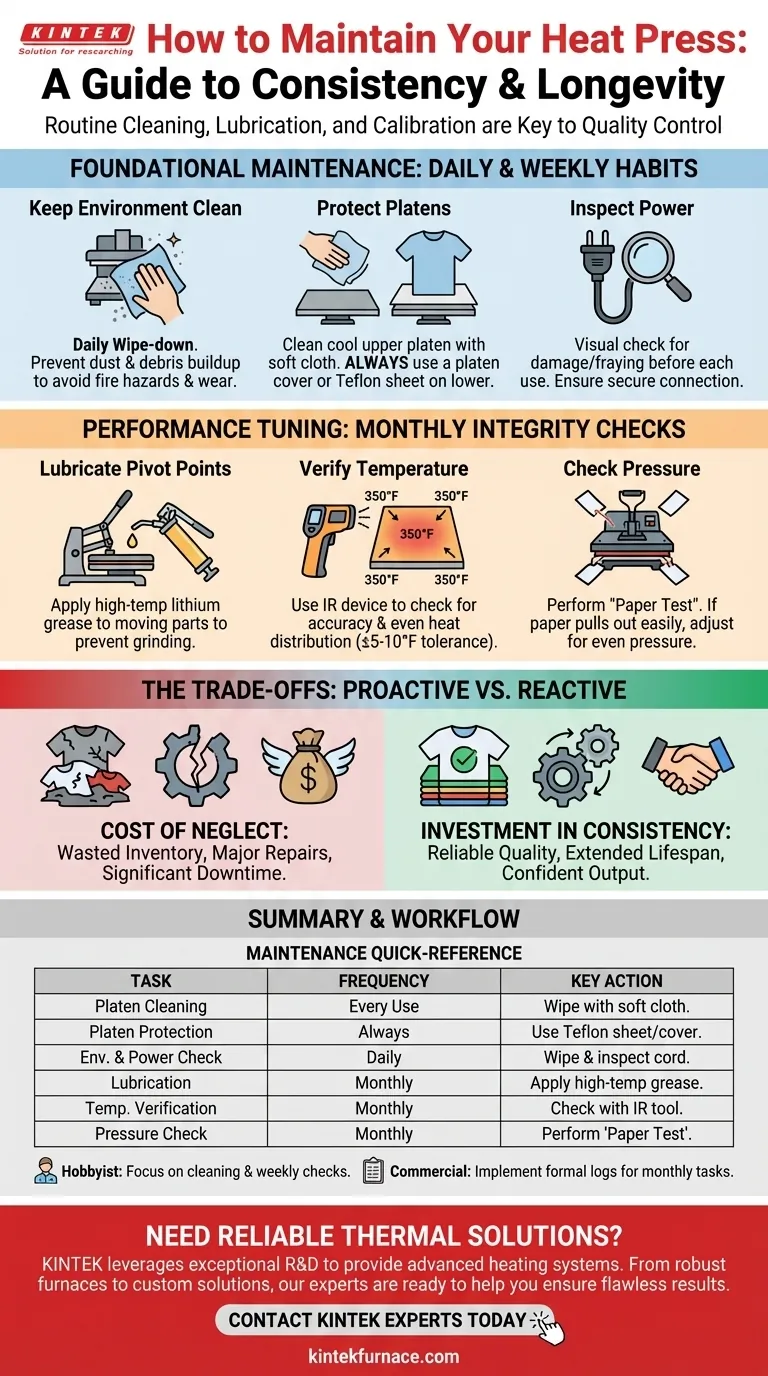

Foundational Maintenance: The Daily and Weekly Checks

These are the non-negotiable habits that form the bedrock of a reliable heat press operation. They prevent the most common and easily avoidable failures.

Keep the Environment Clean and Dust-Free

Your workspace directly impacts your machine's health. Dust, lint, and debris can accumulate on the press, creating a potential fire hazard when exposed to high heat.

Furthermore, these particles can get into the mechanical joints, accelerating wear and causing stiff or inconsistent operation. A simple wipe-down of the machine and surrounding area daily is crucial.

Protect the Platens at All Costs

The platens are the heart of your machine. The upper platen delivers the heat, while the lower platen provides the flat surface. Their condition dictates the quality of your press.

To maintain the upper platen, wipe it down with a soft, non-abrasive cloth when it is cool. If ink or vinyl residue is stuck to it, use a specialized platen cleaner. Never use a razor blade or metal scraper, as this can damage the non-stick coating and cause uneven heating.

Protect the lower platen by always using a platen cover or a non-stick sheet (like a Teflon sheet). This prevents dyes from sublimating onto the silicone pad and makes it easier to slide garments on and off the press.

Inspect the Power Cord and Connections

A faulty power cord is a significant fire risk and can cause inconsistent heating. Before each use, give the cord a quick visual inspection for any signs of fraying, cracking, or damage to the plug. Ensure it is firmly seated in both the machine and the wall outlet.

Performance Tuning: Ensuring Mechanical Integrity

Beyond basic cleanliness, periodic checks are necessary to ensure the machine is performing to its specifications. These steps guarantee that the temperature and pressure you set are the temperature and pressure you get.

Lubricate Key Pivot Points

For manual and semi-automatic clam-shell or swing-away presses, moving parts need lubrication to function smoothly. Once a month, or as recommended by your manufacturer, apply a small amount of high-temperature lithium grease to all pivot points and piston shafts.

This simple step prevents grinding, reduces metal-on-metal wear, and ensures the press opens and closes with minimal effort.

Verify Temperature Accuracy Regularly

The temperature on your digital display may not be the actual temperature of your platen. Over time, thermostats can drift, leading to under-cured or scorched transfers.

At least once a month, use an external device like an infrared (IR) temperature gun or a surface temperature probe to check the heat. Measure at the center and near all four corners to ensure the heat is evenly distributed across the platen. If the reading is off by more than 5-10 degrees, you may need to calibrate your machine or replace the thermostat.

Check for Even Pressure

Uneven pressure is a leading cause of faded spots and peeling designs. A simple way to test this is the "paper test."

Place four small strips of paper in each corner of the lower platen and one in the center. Close and lock the press at your normal operating pressure. If you can easily pull any of the paper strips out, your pressure is uneven and needs adjustment.

Understanding the Trade-offs: Proactive vs. Reactive Maintenance

Failing to maintain your heat press is not a neutral choice; it has direct and costly consequences that go far beyond the machine itself.

The Cost of Neglect

An unmaintained press leads directly to wasted inventory. Inconsistent temperature and pressure will ruin garments and transfer materials, costing you money and time.

Furthermore, ignoring simple lubrication and cleaning accelerates wear on critical components, turning a minor adjustment into a major repair and significant downtime for your business or hobby.

The Investment in Consistency

Spending five minutes a week on maintenance is an investment, not a cost. This proactive approach ensures every press is as good as the last, giving you confidence in your output.

It extends the functional life of your machine by years and transforms it from a potential point of failure into a reliable workhorse.

Making the Right Choice for Your Workflow

Your maintenance schedule should align with your production volume. A consistent routine is what matters most.

- If you are a hobbyist or low-volume user: Focus on keeping the platens clean after every use and performing a quick weekly check of the power cord and overall cleanliness.

- If you are a commercial or high-volume business: Implement a formal log to track monthly lubrication and temperature verification, in addition to daily cleaning protocols.

Ultimately, proper maintenance puts you in complete control of your production quality and the lifespan of your equipment.

Summary Table:

| Maintenance Task | Frequency | Key Action |

|---|---|---|

| Platen Cleaning | After every use | Wipe with a soft cloth; use specialized cleaner for residue. |

| Platen Protection | Always | Use a Teflon sheet or platen cover to prevent damage. |

| Environment & Power Cord Check | Daily | Wipe down machine, clear debris, inspect cord for damage. |

| Lubrication | Monthly | Apply high-temperature grease to pivot points. |

| Temperature Verification | Monthly | Check with an IR thermometer for accuracy and even heating. |

| Pressure Check | Monthly | Perform the "paper test" to ensure even pressure distribution. |

Is inconsistent heat or pressure affecting your print quality? Your heat press is the core of your operation, and its performance is non-negotiable. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, reliable thermal solutions. Whether you need a robust replacement furnace or a custom-engineered heating system tailored to your unique production demands, our team is ready to help.

Protect your investment and ensure flawless results—contact our experts today for a consultation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the applications of hot pressing? Achieve Maximum Material Performance

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- What is a hot press used for? Fabricate Dense, High-Performance Materials

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials