The primary purpose of using the in-situ reaction/hot pressing method is to synthesize a bulk target that possesses both extremely high density and a uniform phase distribution. By applying high temperature and pressure simultaneously within a closed mold, this technique forces raw powders to undergo solid-phase reactions and rapid densification in a single step, creating a high-quality source material for sputtering.

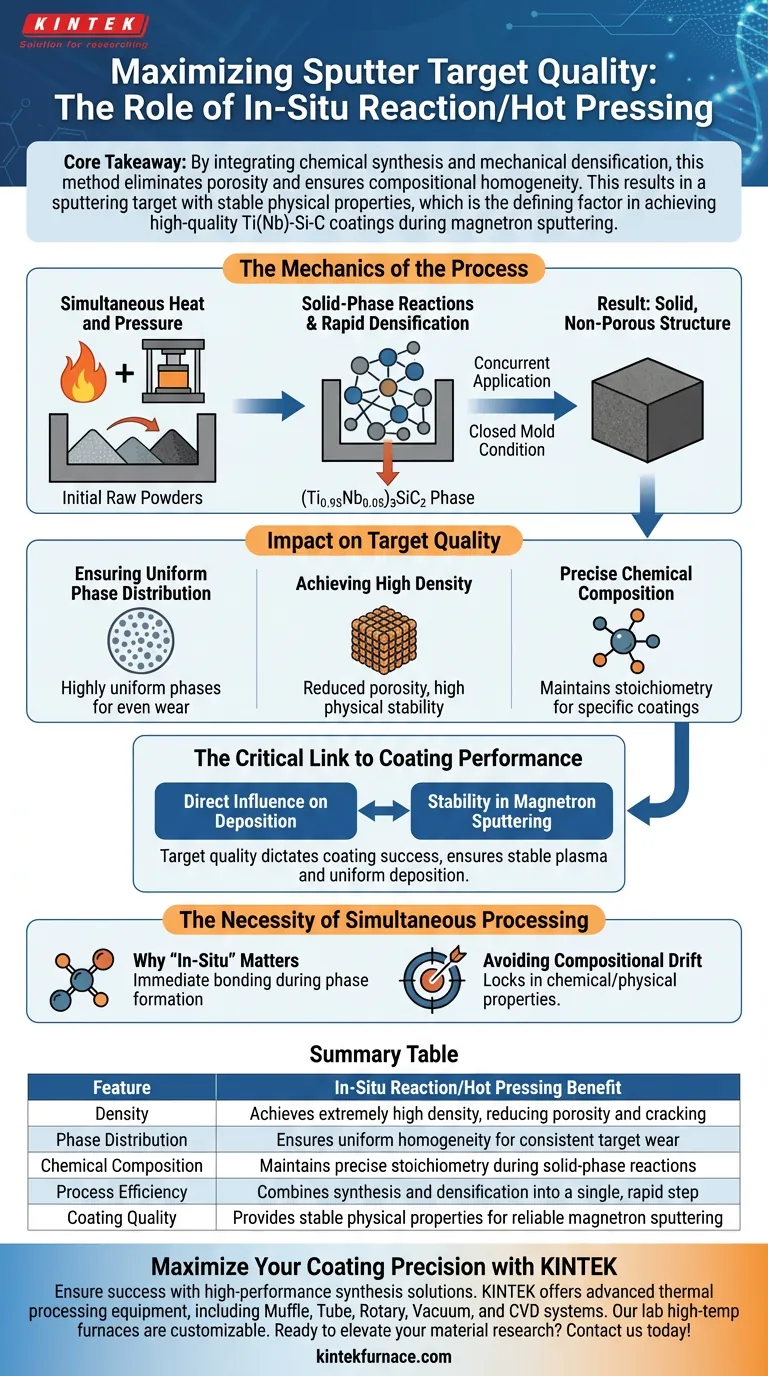

Core Takeaway By integrating chemical synthesis and mechanical densification, this method eliminates porosity and ensures compositional homogeneity. This results in a sputtering target with stable physical properties, which is the defining factor in achieving high-quality Ti(Nb)-Si-C coatings during magnetron sputtering.

The Mechanics of the Process

Simultaneous Heat and Pressure

The defining characteristic of this method is the concurrent application of thermal energy and mechanical force. Instead of sintering a pre-reacted powder, the process uses initial raw powders placed within a closed mold.

Solid-Phase Reactions

Under these extreme conditions, the initial powders undergo an "in-situ" reaction. This means the chemical transformation into the specific (Ti0.95Nb0.05)3SiC2 phase happens directly during the consolidation process, rather than beforehand.

Rapid Densification

The external pressure applied during the reaction phase drives the material to densify quickly. This effectively closes voids and pores that might otherwise remain in the bulk material, resulting in a solid, non-porous structure.

Impact on Target Quality

Ensuring Uniform Phase Distribution

Because the reaction occurs in a controlled, closed environment under pressure, the resulting material achieves a highly uniform distribution of phases. This homogeneity is critical for ensuring the target wears evenly during use.

Achieving High Density

The rapid densification process creates a bulk material with extremely high density. A dense target is essential for physical stability, reducing the risk of cracking or particle generation during the high-energy sputtering process.

Precise Chemical Composition

The closed-mold nature of the process helps maintain stoichiometry. The method ensures the final target retains the precise (Ti0.95Nb0.05)3SiC2 chemical composition required for the specific coating application.

The Critical Link to Coating Performance

Direct Influence on Deposition

The quality of the sputtering target is the upstream variable that dictates downstream success. The stability and composition of the target directly influence the deposition quality of the final Ti(Nb)-Si-C coating.

Stability in Magnetron Sputtering

For magnetron sputtering to function effectively, the target must have stable physical properties. The hot pressing method provides the structural integrity and compositional consistency required to maintain a stable plasma and uniform deposition rate.

The Necessity of Simultaneous Processing

Why "In-Situ" Matters

Separating the reaction and densification steps can often lead to impurities or lower density. By forcing the reaction while pressing, the material bonds at a fundamental level immediately as the phase is formed.

Avoiding Compositional Drift

If the density is low or the phase distribution is uneven, the sputtering process becomes unpredictable. This method is specifically employed to lock in the chemical and physical properties, preventing variations that would degrade the coating's performance.

Making the Right Choice for Your Goal

To ensure the success of your Ti(Nb)-Si-C coating preparation, consider how the target synthesis aligns with your specific requirements:

- If your primary focus is coating consistency: Rely on this method to provide a target with a uniform phase distribution, ensuring the deposited layer matches the intended chemical design.

- If your primary focus is process stability: Prioritize targets made via hot pressing to ensure high density, which prevents target degradation and ensures stable magnetron sputtering behavior.

The in-situ reaction/hot pressing method is not just a manufacturing step; it is a quality assurance measure that guarantees the sputtering target serves as a reliable foundation for advanced coating systems.

Summary Table:

| Feature | In-Situ Reaction/Hot Pressing Benefit |

|---|---|

| Density | Achieves extremely high density, reducing porosity and cracking |

| Phase Distribution | Ensures uniform homogeneity for consistent target wear |

| Chemical Composition | Maintains precise stoichiometry during solid-phase reactions |

| Process Efficiency | Combines synthesis and densification into a single, rapid step |

| Coating Quality | Provides stable physical properties for reliable magnetron sputtering |

Maximize Your Coating Precision with KINTEK

Ensure the success of your Ti(Nb)-Si-C coating preparation with high-performance synthesis solutions. Backed by expert R&D and manufacturing, KINTEK offers a wide range of advanced thermal processing equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet your unique in-situ reaction and densification needs.

Ready to elevate your material research? Contact us today to find your custom furnace solution!

Visual Guide

References

- Xichao Li, Lili Zheng. The Preparation and Properties of Ti(Nb)-Si-C Coating on the Pre-Oxidized Ferritic Stainless Steel for Solid Oxide Fuel Cell Interconnect. DOI: 10.3390/ma17030632

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing

- How does industrial-scale FAST equipment address production challenges? Scale-up Your Sintering Capabilities

- How do graphite molds function during the SPS of Ti-6Al-4Zr-4Nb alloys? Mastering Dual-Action Sintering

- Why are vacuum presses considered versatile tools in various industries? Achieve Perfect Lamination and Forming

- Why is a vacuum environment required in a vacuum hot pressing sintering furnace when preparing ceramic tools containing metal binders? Achieve Purity for Superior Tool Performance

- How does a vacuum hot press machine improve material properties? Achieve Superior Strength and Purity

- Why is adjustable temperature important in a vacuum hot press furnace? Unlock Precision for Superior Materials Processing

- What roles do high-purity, high-strength graphite molds play in SPS? Driving Densification and Precision