Industrial-scale Field Assisted Sintering Technology (FAST) equipment fundamentally solves the scalability gap by enabling the production of full-scale components rather than just experimental coupons. Unlike laboratory units restricted to small samples, industrial systems accommodate significantly larger material volumes while ensuring that critical material properties are not lost during the scale-up process.

The primary value of industrial FAST systems lies in their ability to bridge the gap between material science theory and commercial reality. By producing large-scale billets that retain synergistic strengthening effects, these systems allow for standardized mechanical testing and viable component manufacturing.

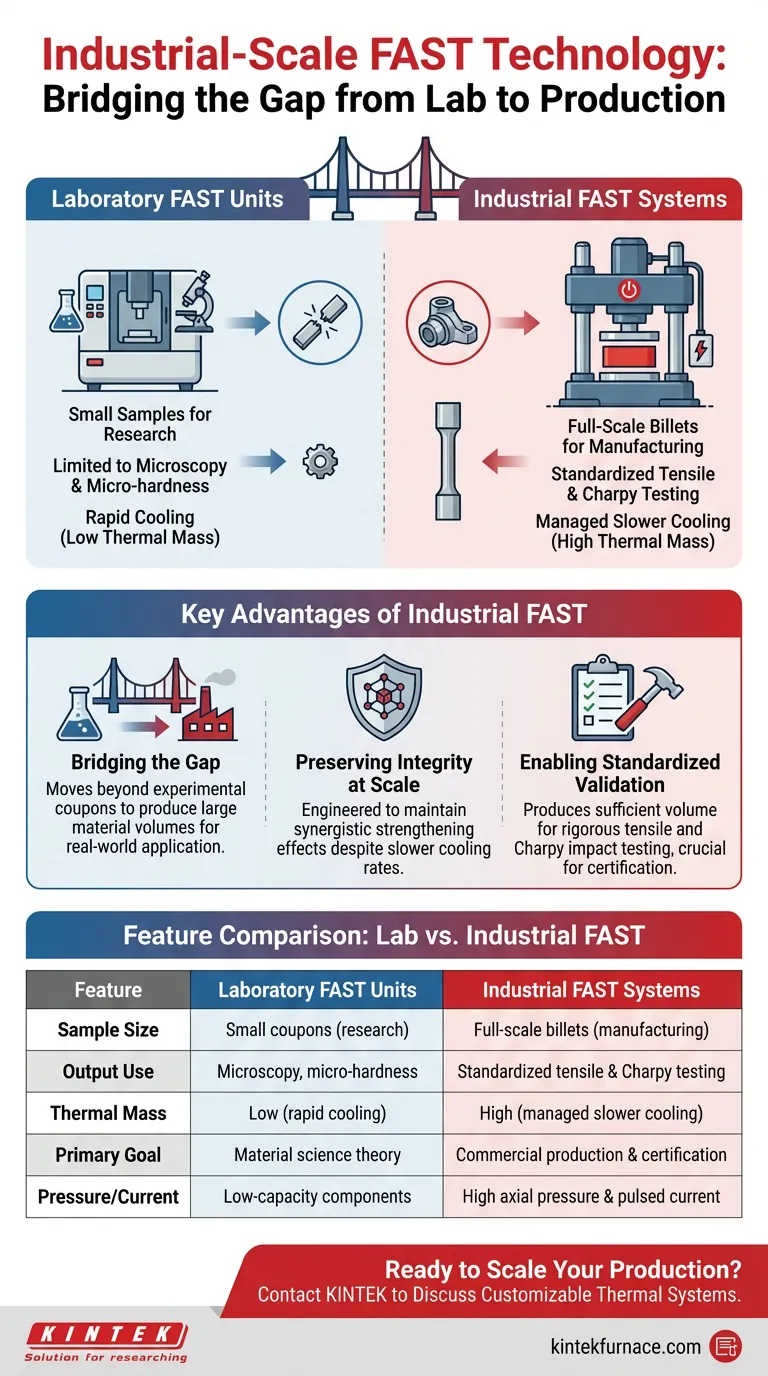

Bridging the Gap from Lab to Factory

Moving Beyond Small Samples

Laboratory-scale units are essential for initial research but are inherently limited by their size capacity. They typically produce small samples suitable for microscopy or micro-hardness testing, but insufficient for real-world application.

Industrial-scale equipment facilitates the transition from these small laboratory samples to large-scale billets. This capability allows engineers to process the material volumes necessary to create full-sized components.

Operational Mechanics of Large-Scale Systems

To handle increased volumes, industrial FAST systems employ specific mechanical and electrical strategies.

These systems utilize high axial pressure combined with pulsed current for direct heating. This dual approach ensures effective consolidation and densification throughout the larger material mass, which is critical for structural integrity.

Preserving Material Integrity at Scale

Managing Thermal Dynamics

One of the most significant challenges in scaling up sintering processes is managing the thermal history of a large part. Larger billets inherently experience relatively slower cooling rates compared to tiny lab samples.

Despite this change in thermal dynamics, industrial FAST equipment is engineered to maintain synergistic strengthening effects. The technology ensures that the beneficial properties achieved in the lab are not sacrificed when the material is produced in bulk.

Enabling Standardized Validation

overcoming the "Coupon" Limitation

A major hurdle in materials engineering is validating a new material's performance using industry standards. Small lab samples often cannot be machined into standard test specimens.

Producing Testable Volumes

Industrial-scale FAST equipment produces enough material volume to machine standard mechanical test specimens. This allows for rigorous validation through tensile testing and Charpy impact tests, providing the data needed for certification and engineering analysis.

Understanding the Trade-offs

Thermal Mass Implications

While industrial units are capable of maintaining material properties, the physics of large-scale heating introduces inevitable differences. The slower cooling rates mentioned are a direct result of the increased thermal mass of the large billets.

Process Translation

Because of these thermal differences, parameters developed on a lab unit may not transfer perfectly to an industrial unit. Users must anticipate a period of optimization to ensure that the strengthening effects are retained despite the slower cooling profile.

Making the Right Choice for Your Goal

To determine if you are ready to transition to industrial-scale FAST equipment, consider your current objectives:

- If your primary focus is material qualification: Utilization of industrial equipment is essential to generate the material volume required for standardized tensile and Charpy impact testing.

- If your primary focus is component manufacturing: You must move to industrial systems to produce full-scale billets that maintain strengthening effects despite the thermal challenges of larger volumes.

Industrial FAST technology is the definitive step required to transform a promising material concept into a certified, market-ready product.

Summary Table:

| Feature | Laboratory FAST Units | Industrial FAST Systems |

|---|---|---|

| Sample Size | Small coupons for research | Full-scale billets for manufacturing |

| Output Use | Microscopy & micro-hardness | Standardized tensile & Charpy testing |

| Thermal Mass | Low (rapid cooling) | High (managed slower cooling) |

| Primary Goal | Material science theory | Commercial production & certification |

| Pressure/Current | Low-capacity components | High axial pressure & pulsed current |

Accelerate Your Transition from Lab to Market with KINTEK

Bridge the gap between material research and commercial reality with KINTEK’s advanced sintering solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique material needs. Whether you are qualifying new materials through standardized testing or moving into full-scale component manufacturing, our high-precision equipment ensures you maintain critical material properties at any scale.

Ready to scale your production? Contact us today to discuss how our customizable thermal systems can optimize your industrial FAST processes.

Visual Guide

References

- Samuel Lister, Martin Jackson. Titanium‐S23: A New Alloy with Ultra‐High Tensile Toughness Directly from the Solid‐State Processing of Recycled Ti–6Al–4V and Ti–5Al–5Mo–5V–3Cr Powders using Field Assisted Sintering Technology. DOI: 10.1002/adem.202500572

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does temperature control at 950°C affect SiC/Cu-Al2O3 composites? Optimize Sintering for High Strength

- What is the role of the vacuum environment in SiC/ZTA sintering? Enhance Densification & Material Purity

- What is the primary function of a vacuum hot press furnace in the preparation of Fe-based amorphous alloy/aluminum microlaminated composites? Achieve Perfect Solid-State Bonding

- What functions does a graphite mold serve during ZnS vacuum hot pressing? Optimize Density and Optical Purity

- What are the main advantages of hot pressing in powder metallurgy? Achieve High-Density, Fine-Grained Components

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- How does the pressure control function in a vacuum hot pressing sintering furnace influence ceramic tool materials?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity