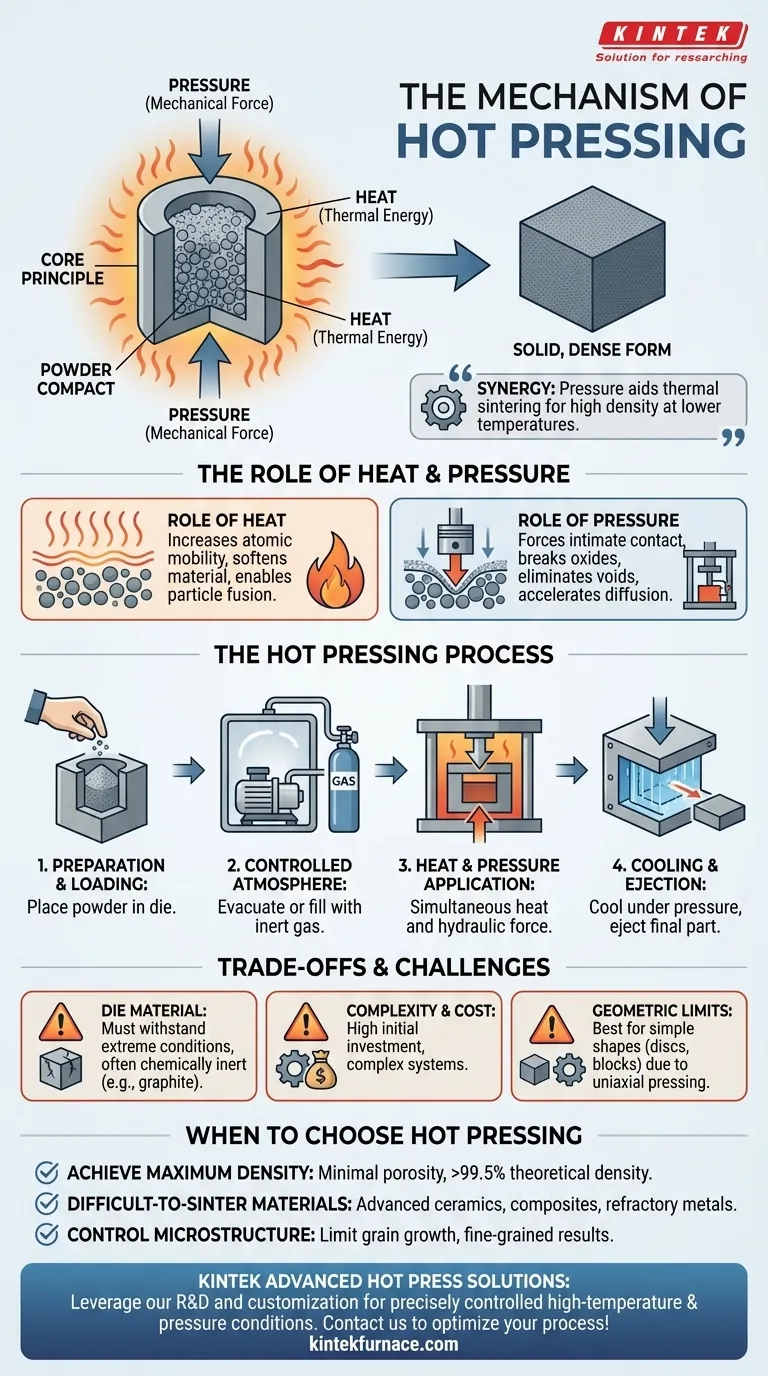

At its core, hot pressing is a materials manufacturing process that simultaneously applies high temperature and high pressure to a powder compact. This is done inside a die to consolidate the powder into a solid, dense form. The combination of heat and pressure accelerates the bonding between powder particles, resulting in a final part with superior density and mechanical properties.

The fundamental mechanism of hot pressing is using external pressure as a powerful driving force to aid the thermal process of sintering. This synergy allows for the creation of highly dense materials, often with near-zero porosity, at lower temperatures or in shorter times than conventional furnace sintering alone.

The Core Principle: Heat and Pressure in Synergy

Hot pressing is fundamentally about accelerating densification. It achieves this by combining thermal energy (heat) with mechanical energy (pressure) to overcome the barriers that prevent powder particles from forming a solid mass.

The Role of Heat

Heat is the primary enabler of particle bonding. It increases the atomic mobility within the powder particles, softening the material and making it more plastic. This allows the particles to deform and fuse together more easily where they touch.

The Role of Pressure

Pressure provides the critical driving force. It mechanically forces particles into intimate contact, breaking down surface oxides and eliminating the voids (porosity) between them. This applied stress significantly enhances the rate of material flow and diffusion, which are the core mechanisms of densification.

The Synergistic Effect

Neither heat nor pressure alone is as effective. By applying them together, the process creates a final part with a density that is often close to the theoretical maximum for the material. This synergy allows for full densification to be achieved at lower temperatures, which is crucial for preventing unwanted grain growth and preserving a fine-grained microstructure.

A Breakdown of the Hot Pressing Process

While specific parameters vary, the operational sequence of a hot press follows a clear, logical path designed for control and precision.

1. Preparation and Loading

The process begins by placing the material, typically in powder form, into a die. The die cavity defines the basic shape of the final component.

2. Creating a Controlled Atmosphere

The die assembly is placed inside a chamber which is then evacuated to create a vacuum or filled with a protective inert gas (like argon). This step is critical to prevent the material from oxidizing or reacting with air at high temperatures.

3. Simultaneous Heat and Pressure Application

Heat is applied to the die and the material within it. Concurrently, a hydraulic or mechanical ram applies immense pressure via a punch onto the material. This combined action forces the softened particles to consolidate and fuse together, eliminating porosity.

4. Cooling and Ejection

Once the desired density is achieved, the component is cooled under pressure to maintain its consolidated form. After cooling, the pressure is released, and the final, dense part (often called a "billet") is ejected from the die.

Understanding the Trade-offs and Challenges

While powerful, hot pressing is not a universal solution. Understanding its inherent limitations is key to using it effectively.

The Die Material Dilemma

The single greatest challenge is the die material. It must simultaneously withstand extreme pressure at high temperatures while remaining chemically inert, meaning it cannot react with the powder it's pressing. Graphite is a common choice, but its use introduces limitations on pressure and lifespan.

Process Complexity and Cost

Hot press systems are more complex and expensive than conventional furnaces or cold presses. The requirement for vacuum or inert gas systems, combined with robust heating and high-pressure hydraulic components, increases both the initial investment and operational costs.

Geometric Limitations

Due to the nature of uniaxial pressing (pressure from one direction), hot pressing is best suited for producing simple shapes like discs, blocks, and cylinders. Complex, intricate geometries are very difficult to achieve with this method.

Making the Right Choice for Your Goal

Deciding whether to use hot pressing depends entirely on your material and performance objectives.

- If your primary focus is achieving maximum density: Hot pressing is the premier choice for creating parts with minimal porosity, often exceeding 99.5% of the material's theoretical density.

- If you are working with difficult-to-sinter materials: For advanced ceramics, composites, or refractory metals that resist densification, the applied pressure of hot pressing provides the necessary force to achieve consolidation.

- If you need to control microstructure: By enabling densification at lower temperatures, hot pressing is excellent for limiting unwanted grain growth and producing parts with fine, high-strength microstructures.

Ultimately, understanding the interplay of heat, pressure, and atmosphere empowers you to leverage hot pressing for manufacturing advanced materials that are otherwise unattainable.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Simultaneous application of high temperature and uniaxial pressure to a powder in a die. |

| Primary Goal | Achieve near-theoretical density and superior mechanical properties. |

| Key Mechanisms | Enhanced particle deformation, diffusion, and bonding accelerated by pressure. |

| Ideal For | Difficult-to-sinter materials (e.g., advanced ceramics, composites), applications requiring maximum density. |

| Main Limitation | Geometric simplicity of parts; high equipment and die costs. |

Need to achieve maximum material density and performance? KINTEK's advanced hot press solutions leverage our exceptional R&D and in-house manufacturing to deliver precisely controlled high-temperature and high-pressure conditions. Whether you are developing advanced ceramics, composites, or other specialized materials, our furnaces and strong deep customization capabilities are designed to meet your unique research and production requirements. Contact our experts today to discuss how we can help you optimize your hot pressing process!

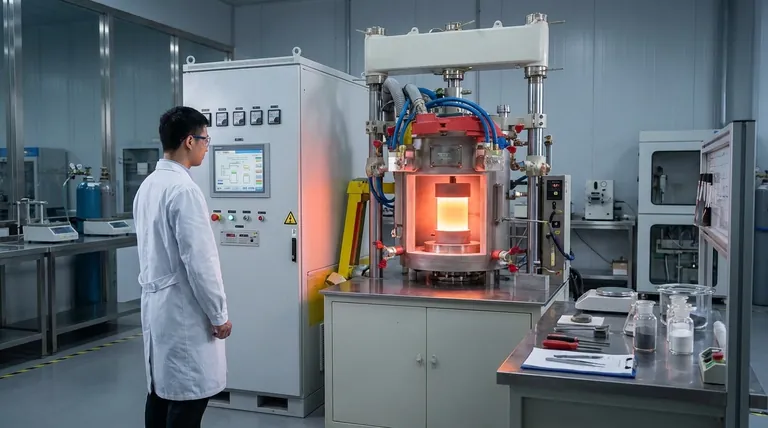

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results