Precise pressure control acts as a critical regulator during the sintering holding phase, directly determining the final density and grain size of ceramic tool materials. It facilitates the movement of the liquid phase to fill voids while simultaneously inhibiting abnormal grain growth. This process yields a fine, uniformly distributed microstructure that significantly enhances both hardness and fracture toughness.

By serving as an external driving force for densification, controlled pressure allows for void elimination and atomic diffusion at lower temperatures. This prevents the excessive grain coarsening commonly associated with high-heat pressureless sintering, resulting in a superior, fine-grained composite.

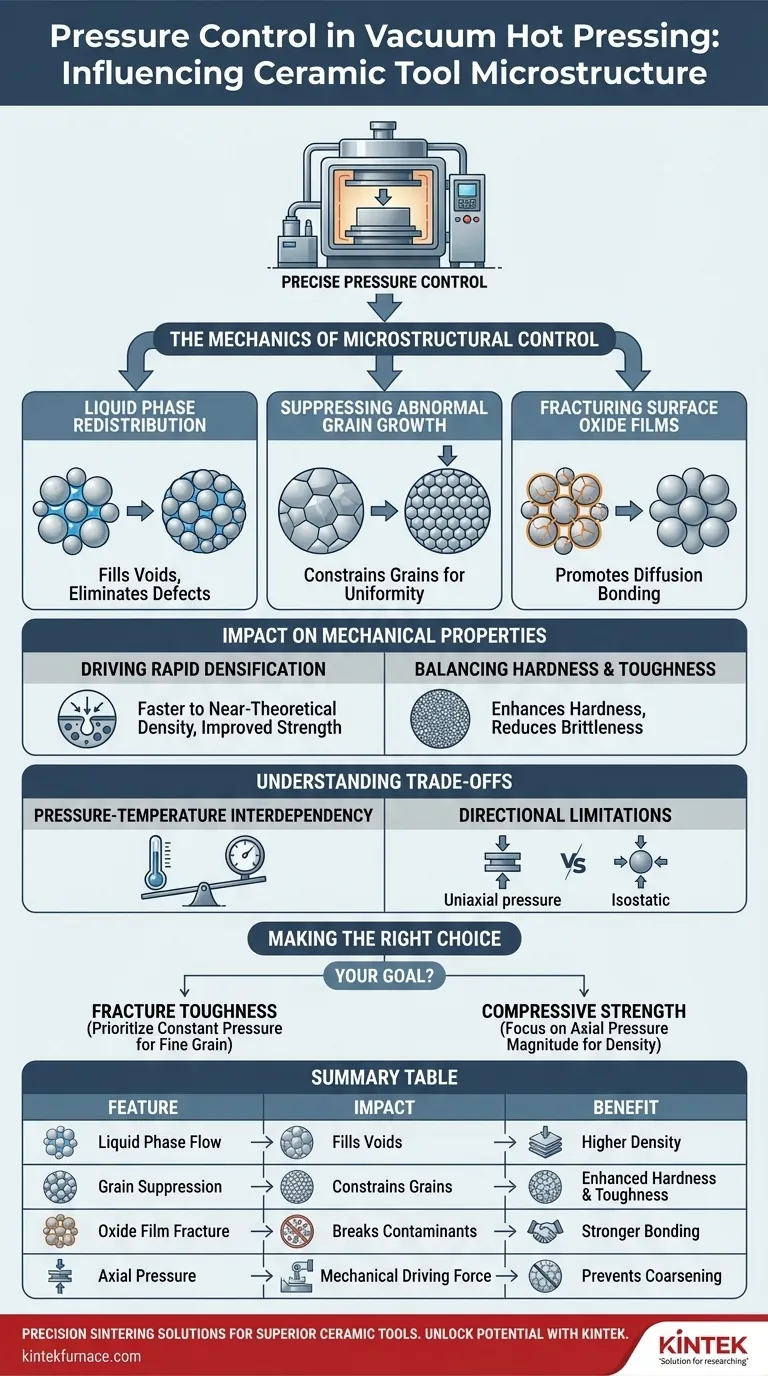

The Mechanics of Microstructural Control

Facilitating Liquid Phase Redistribution

During the sintering holding phase, the application of constant pressure is essential for managing porosity.

Pressure acts as a mechanical force that pushes the liquid phase into interstitial voids.

This ensures that gaps between particles are filled efficiently, eliminating defects that could lead to structural weakness.

Suppressing Abnormal Grain Growth

One of the primary risks during sintering is the uncontrolled expansion of grain size, which reduces material strength.

Precise pressure control physically constrains the grains, preventing them from growing abnormally large.

This results in a fine, uniform grain structure, which is the hallmark of high-performance ceramic tools.

Fracturing Surface Oxide Films

To achieve solid bonding, particles must be in direct contact without interference from surface contaminants.

The pressure applied in a vacuum hot press helps fracture the oxide films that naturally form on powder surfaces.

Breaking these films promotes diffusion bonding, allowing atoms to interlock more effectively for a cohesive structure.

The Impact on Mechanical Properties

Driving Rapid Densification

Pressure provides an additional driving force beyond thermal energy to close pores.

This allows the material to reach near-theoretical density much faster than in pressureless environments.

Higher relative density directly correlates to improved compressive strength and structural integrity.

Balancing Hardness and Toughness

A fine-grained microstructure is critical for the mechanical performance of ceramic tools.

By limiting grain growth and ensuring uniform distribution, pressure control enhances the material's hardness.

Simultaneously, the reduction of voids improves fracture toughness, making the tool less brittle and more durable under stress.

Understanding the Trade-offs

The Pressure-Temperature Interdependency

While pressure is a powerful tool, it cannot compensate for incorrect thermal management.

Pressure allows for sintering at lower temperatures, which helps preserve fine grain structures, but the temperature must still be sufficient to trigger reaction diffusion.

If the temperature is too low, even high pressure may not generate the necessary intermediate phases (such as the conversion of Titanium to Al3Ti) required for reinforcement.

Directional Limitations

Vacuum hot pressing typically applies pressure axially (from one direction).

While this creates excellent density, it can occasionally lead to anisotropic properties if the particles align preferentially along the stress axis.

You must evaluate if your specific component geometry requires isostatic pressure (pressure from all sides) rather than the uniaxial pressure provided here.

Making the Right Choice for Your Goal

To maximize the performance of your ceramic tool materials, align your pressure strategy with your specific mechanical requirements:

- If your primary focus is Fracture Toughness: Prioritize constant pressure during the holding phase to inhibit grain growth, ensuring the microstructure remains fine and uniform.

- If your primary focus is Compressive Strength: Focus on the magnitude of the axial pressure (e.g., 20 MPa) to drive maximum pore closure and achieve the highest possible relative density.

Mastering pressure control allows you to decouple densification from grain growth, achieving a material balance that temperature alone cannot provide.

Summary Table:

| Feature | Impact on Microstructure | Mechanical Benefit |

|---|---|---|

| Liquid Phase Flow | Fills interstitial voids and eliminates pores | Higher relative density & structural integrity |

| Grain Suppression | Constrains grains to a fine, uniform size | Enhanced hardness & fracture toughness |

| Oxide Film Fracture | Breaks surface contaminants for direct contact | Stronger atomic diffusion bonding |

| Axial Pressure | Provides mechanical driving force at lower temps | Prevents heat-induced grain coarsening |

Precision Sintering Solutions for Superior Ceramic Tools

Unlock the full potential of your materials with KINTEK. Our vacuum hot pressing sintering furnaces provide the precise pressure and thermal regulation required to achieve near-theoretical density and fine-grained microstructures.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique processing needs. Whether you are optimizing for fracture toughness or compressive strength, our engineering team is ready to help you design the perfect thermal solution.

Ready to elevate your material performance? Contact us today to discuss your project!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is hot pressing and what does it involve? Unlock Superior Material Density and Strength

- What role does a vacuum hot pressing furnace play in (Ti2AlC + Al2O3)p/TiAl fabrication? Achieve 100% Densification

- How does the vacuum environment facilitate the densification of ZnS ceramics? Unlock High-Performance Liquid Sintering

- How does vacuum hot pressing equipment enhance the matrix quality of diamond tools through improved wettability? Unlock Superior Diamond Retention

- What Role Does a Graphite Mold Play in Vacuum Hot Pressing? Enhancing Composite Sintering Efficiency

- How do you maintain a heat press machine? A Proactive Guide to Consistent Prints & Longevity

- Why is a vacuum hot press furnace preferred over a conventional high-temperature sintering furnace for preparing ZrC-SiC composites? Achieve Superior Density and Purity

- What is the core processing value of a vacuum hot pressing sintering furnace? Master AZ31 Magnesium Alloy Density