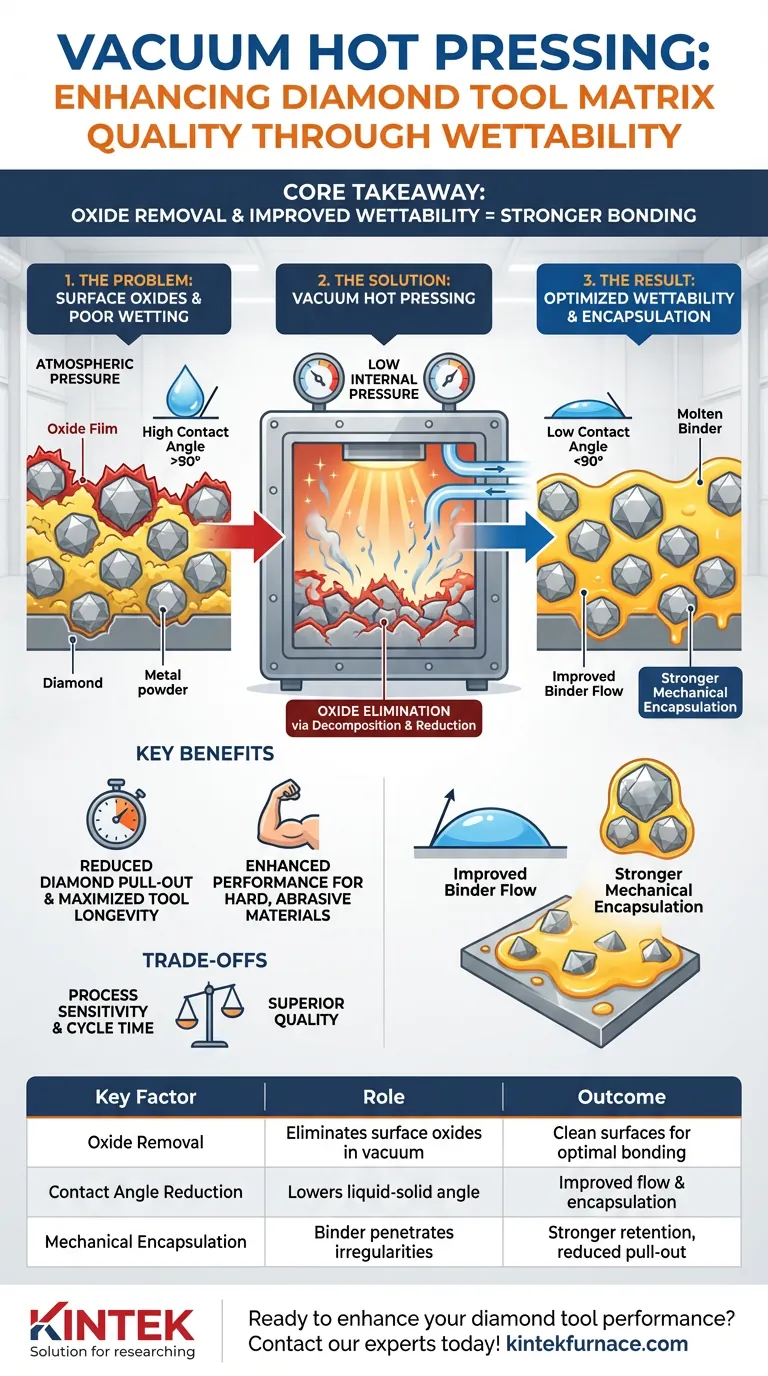

Vacuum hot pressing enhances matrix quality by lowering internal pressure to chemically purify the sintering environment, specifically removing oxide films from powder surfaces. This purification lowers the contact angle at the liquid-solid interface, allowing the molten binder metal to spread effectively and tightly encapsulate the diamond particles.

Core Takeaway The presence of surface oxides is the primary adversary of strong metal-to-diamond bonding. Vacuum hot pressing eliminates these oxides through decomposition and reduction, transforming the binder into a highly fluid medium that fully "wets" the diamond skeleton rather than merely surrounding it.

The Mechanism of Purification

Eliminating the Oxide Barrier

In standard sintering environments, metal powders and diamond surfaces often retain a thin layer of oxides. These oxides act as a physical barrier, preventing the molten binder from bonding with the diamond.

The Role of Low Internal Pressure

Vacuum hot pressing lowers the internal pressure of the sintering chamber. This low-pressure environment facilitates the decomposition and volatilization of these oxide films, effectively stripping away the impurities that hinder adhesion.

Utilizing a Reducing Environment

Beyond simple evaporation, the process often creates a reducing environment. This actively reacts with and reduces metal oxides, ensuring the raw materials are chemically clean before the bonding phase begins.

Transforming Surface Physics

Lowering the Contact Angle

Wettability is defined by the "contact angle" between a liquid and a solid surface. A high contact angle causes the liquid to bead up (poor wetting), while a low angle causes it to spread (good wetting).

Optimizing the Liquid-Solid Interface

By purifying the surface of the diamond and the metal powder, vacuum hot pressing significantly lowers the contact angle. This ensures the binder metal does not just sit on top of the diamond but flows across it, penetrating microscopic surface irregularities.

Strengthening Mechanical Encapsulation

The result of this improved flow is superior encapsulation. The diamond is held firmly within the matrix, drastically reducing the likelihood of premature "pull-out" during high-stress cutting operations.

Understanding the Trade-offs

Process Sensitivity

While vacuum hot pressing yields superior results, it introduces complexity. The equipment requires rigorous maintenance to ensure seal integrity; even minor vacuum leaks can reintroduce oxygen, negating the wettability benefits.

Cycle Time Implications

Achieving a high vacuum and ensuring complete oxide volatilization can extend cycle times compared to atmospheric pressing. Manufacturers must balance the need for maximum retention strength against production throughput requirements.

Making the Right Choice for Your Production

To determine if vacuum hot pressing is the correct solution for your specific application, consider your performance metrics:

- If your primary focus is tool longevity: Prioritize vacuum hot pressing to maximize diamond retention, as this prevents expensive diamonds from being wasted through premature pull-out.

- If your primary focus is cutting hard, abrasive materials: Use this method to ensure the matrix is free of embrittling oxides, providing the toughness required for heavy-duty applications.

By ensuring the binder truly wets the diamond, you transition from a simple mechanical mixture to a fully integrated composite material.

Summary Table:

| Key Factor | Role in Enhancing Matrix Quality | Outcome |

|---|---|---|

| Oxide Removal | Eliminates surface oxides via decomposition/reduction in vacuum | Chemically clean surfaces for optimal bonding |

| Contact Angle Reduction | Lowers liquid-solid contact angle through surface purification | Improved binder flow and diamond encapsulation |

| Mechanical Encapsulation | Ensures binder penetrates diamond surface irregularities | Stronger diamond retention, reduced pull-out |

| Process Sensitivity | Requires maintained vacuum integrity to prevent oxygen reintroduction | Consistent high-quality results with proper equipment care |

Ready to enhance your diamond tool performance with superior matrix quality?

At KINTEK, our vacuum hot pressing systems are engineered to deliver the precise environment needed for optimal binder-diamond wettability. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique production needs.

Maximize your tool longevity and cutting efficiency – Contact our experts today to discuss how our solutions can transform your diamond tool manufacturing process!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does the pressurization system of a vacuum hot press affect SiC/TB8 composites? Optimize Matrix Densification

- What are the advantages of SPS for BCZY712 electrolytes? Achieve 98% Density and Superior Proton Conductivity

- What are the advantages of using a VHP furnace over CVD for ZnS? Boost Strength and Efficiency with Vacuum Hot Pressing

- What is the role of HIP equipment in the diffusion bonding of 6061 aluminum alloy? Achieve High-Integrity Metallurgy

- What advantages does a vacuum hot press furnace demonstrate for Fe-Cu-Ni-Sn-VN composites? Superior Nanostructure Prep

- How does a hot pressing (HP) system achieve full densification? Achieve 100% Density in Ti-5Al-4W-2Fe Alloys

- How does the capability for long-duration temperature control in a vacuum hot pressing furnace improve ZnS ceramics?

- What applications does Vacuum Hot Press technology have in the electronics and semiconductor industry? Unlock High-Performance Component Manufacturing