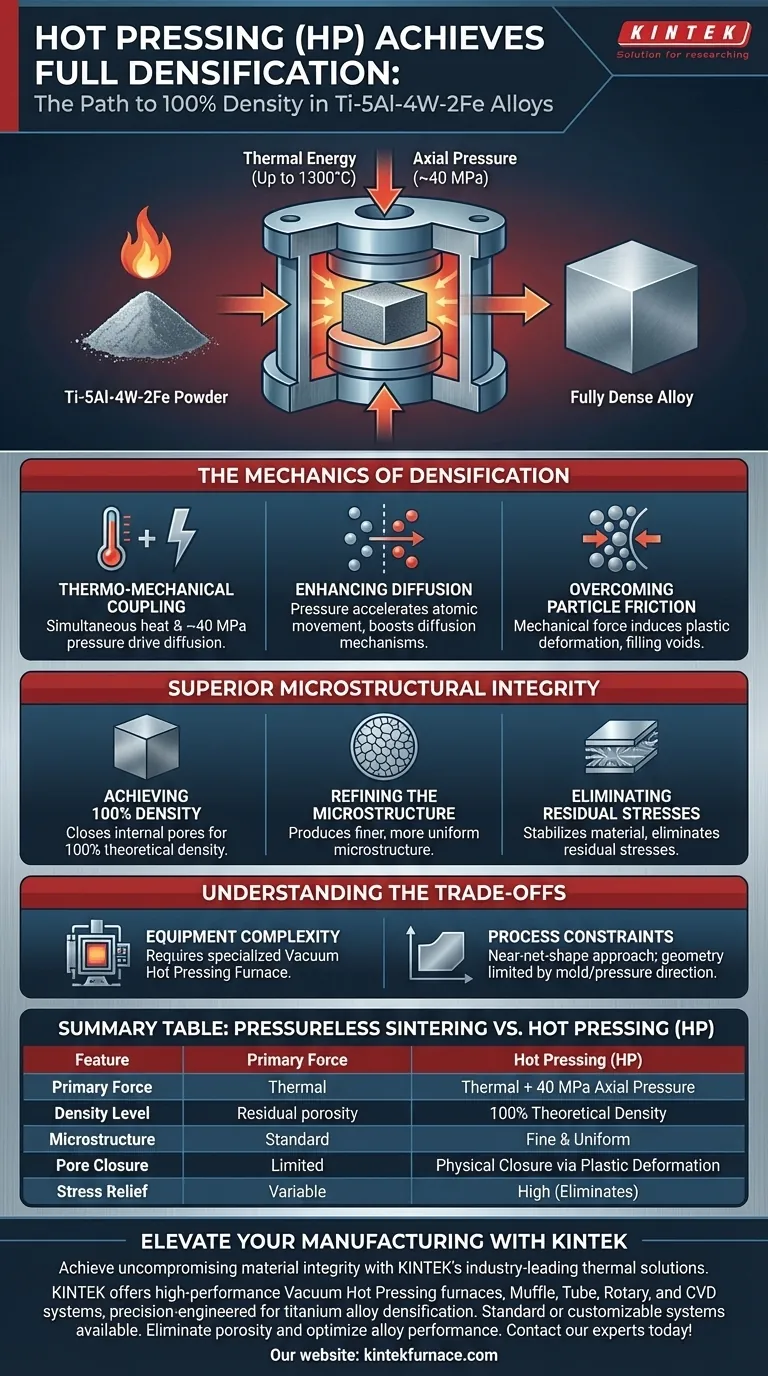

Hot pressing (HP) achieves full densification in Ti-5Al-4W-2Fe alloys by applying simultaneous thermal energy and significant axial pressure, typically around 40 MPa. This process utilizes thermo-mechanical coupling to drive diffusion mechanisms that are insufficient in pressureless environments. Consequently, the system effectively closes internal pores to reach 100% of the alloy's theoretical density.

The core advantage of hot pressing lies in its ability to overcome particle friction through mechanical force. By inducing plastic deformation and diffusion creep, the system eliminates voids and residual stresses that conventional sintering cannot address.

The Mechanics of Densification

Thermo-Mechanical Coupling

The primary driver for densification in this system is the simultaneous application of heat and force. While standard sintering relies solely on thermal energy, hot pressing introduces axial pressure (approximately 40 MPa) during the heating cycle.

Enhancing Diffusion

This combination creates a "thermo-mechanical coupling" effect. The external pressure significantly enhances the natural mechanisms of diffusion, accelerating the movement of atoms across particle boundaries.

Overcoming Particle Friction

At the microscopic level, powder particles resist compaction due to friction. The axial pressure helps overcome this resistance, forcing particles into tighter contact and initiating plastic deformation. This ensures that voids between particles are physically filled.

Superior Microstructural Integrity

Achieving 100% Density

Unlike pressureless sintering, which often leaves residual porosity, hot pressing allows the Ti-5Al-4W-2Fe alloy to reach its 100% theoretical density. The mechanical force effectively closes internal pores that thermal energy alone cannot eliminate.

Refining the Microstructure

Beyond simple density, the process yields a superior internal structure. The rapid densification produces a finer and more uniform microstructure, which is critical for the mechanical performance of titanium alloys.

Eliminating Residual Stresses

The HP process does not just compact the material; it stabilizes it. The specific processing conditions help eliminate residual stresses within the alloy, resulting in a more mechanically stable final component.

Understanding the Trade-offs

Equipment Complexity

Achieving these results requires a specialized Vacuum Hot Pressing Furnace. Unlike simple sintering ovens, these systems must maintain high temperatures (often up to 1300°C) while simultaneously exerting precise mechanical hydraulic force.

Process Constraints

The method relies on a "near-net-shape" approach. While it produces high-quality parts, the geometry is often limited by the mold and the direction of the axial pressure compared to free-form sintering techniques.

Making the Right Choice for Your Goal

To determine if Hot Pressing is the correct manufacturing route for your Ti-5Al-4W-2Fe components, consider your specific performance requirements.

- If your primary focus is maximum material density: Hot pressing is essential, as it is the reliable path to achieving 100% theoretical density and fully closing internal pores.

- If your primary focus is microstructural uniformity: This method is superior to pressureless sintering, as it produces finer grains and eliminates residual stresses for better mechanical reliability.

By combining heat and pressure, hot pressing transforms metal powder into a fully dense, high-performance alloy that pressureless methods simply cannot match.

Summary Table:

| Feature | Pressureless Sintering | Hot Pressing (HP) System |

|---|---|---|

| Primary Force | Thermal energy only | Thermal energy + 40 MPa Axial pressure |

| Density Level | Residual porosity remains | 100% Theoretical density |

| Microstructure | Standard grain growth | Fine and uniform microstructure |

| Pore Closure | Limited diffusion | Physical closure via plastic deformation |

| Stress Relief | Variable | High (Eliminates residual stresses) |

Elevate Your Advanced Material Manufacturing with KINTEK

Achieve uncompromising material integrity with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Hot Pressing furnaces, Muffle, Tube, Rotary, and CVD systems, all precision-engineered to meet the rigorous demands of titanium alloy densification. Whether you require a standard configuration or a fully customizable system for unique research needs, our technology ensures 100% theoretical density and superior microstructural control for your lab or production facility.

Ready to eliminate porosity and optimize your alloy performance? Contact our engineering experts today to find the perfect high-temperature solution for your application.

Visual Guide

References

- Mai Essam, Nabil Fatahalla. Processing of Ti–5Al–4W–2Fe Alloy Using Different Powder Metallurgy Routes to Improve Its Implementation in Structural Applications. DOI: 10.1007/s13369-024-09834-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-strength graphite mold play in hot-press sintering? Optimize Al2O3/TiC/SiC(w) Density

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How are vacuum hot pressing sintering furnaces classified based on their operating temperature? A Guide to Low, Medium, and High-Temp Ranges

- How does the heating mechanism of Spark Plasma Sintering (SPS) function? Enhance TiC/SiC Composite Fabrication

- What role does Hexagonal Boron Nitride (h-BN) coating play in SPS molds? Protect Your Tooling and Purity

- What types of shapes can be manufactured using vacuum hot pressing? From Simple Blocks to Complex Components

- What is the core function of a flat tablet press in CSP? Achieve High-Pressure Densification for CaF2 Ceramics

- What is the vacuum hot pressing technique? Achieve Maximum Density & Purity for Advanced Materials