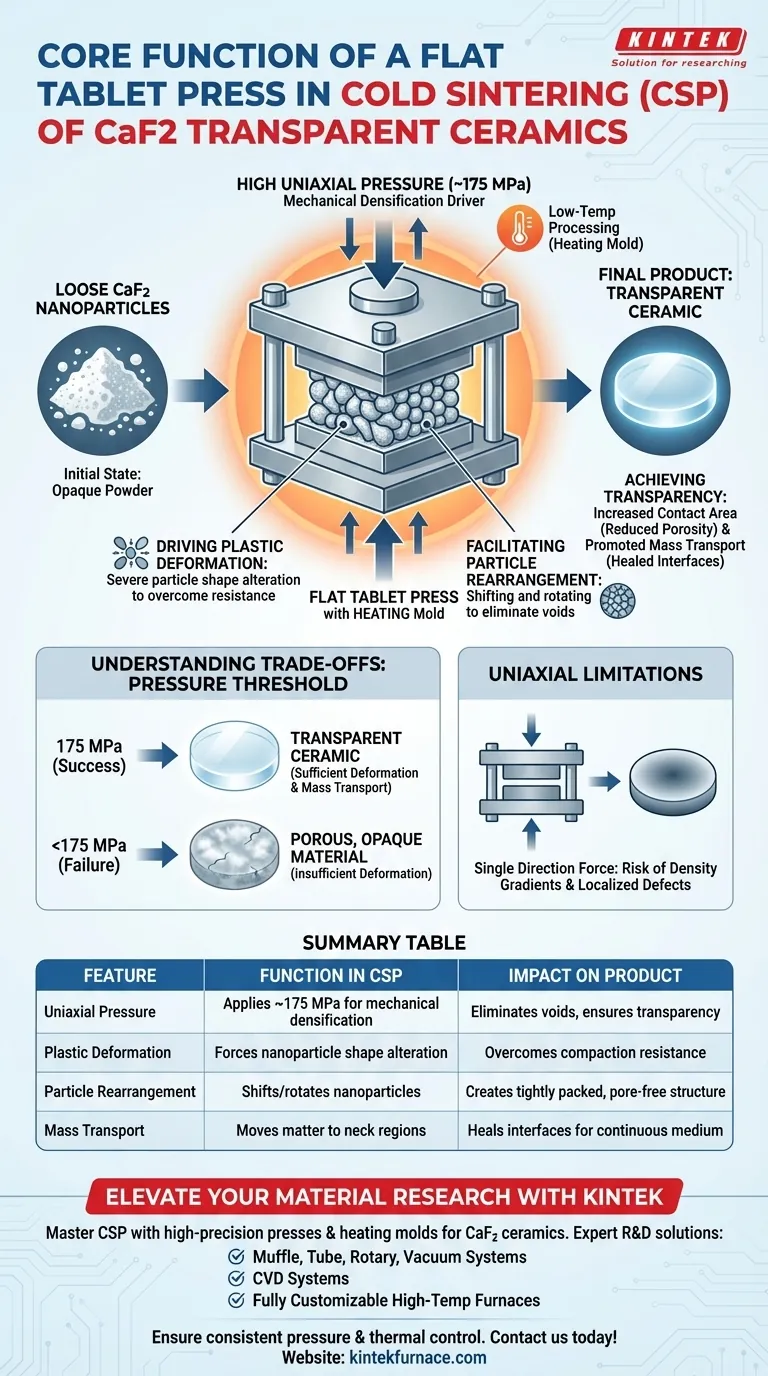

The core function of a flat tablet press in the cold sintering process (CSP) of CaF2-based transparent ceramics is to apply high uniaxial pressure, typically around 175 MPa, to drive mechanical densification. This mechanical force generates severe plastic deformation and rearrangement of the CaF2 nanoparticles, which are the fundamental physical mechanisms required to bond the material at low temperatures.

In the absence of high thermal energy used in traditional sintering, the flat tablet press utilizes mechanical pressure to maximize particle contact area and facilitate mass transport, enabling the creation of transparent ceramics.

The Mechanics of Pressure-Assisted Sintering

Driving Plastic Deformation

The press acts as the primary energy source for altering particle shape.

By applying high pressure (e.g., 175 MPa), the machine forces the CaF2 nanoparticles to undergo severe plastic deformation. This physical alteration is necessary to overcome the material's resistance to compaction.

Facilitating Particle Rearrangement

Beyond deformation, the uniaxial pressure forces the nanoparticles to shift and rotate.

This rearrangement eliminates voids between particles, creating a tightly packed structure that is a prerequisite for a dense, solid final product.

Achieving Transparency Through Densification

Increasing Contact Area

The transparency of the final ceramic is directly linked to how well the particles fuse.

The pressure applied by the press significantly increases the contact area between individual nanoparticles. This proximity is critical for reducing porosity, which is the main cause of opacity in ceramics.

Promoting Mass Transport

Densification requires material to move across particle boundaries.

The high pressure promotes mass transport—the movement of matter from the particles to the neck regions between them. This mechanism "heals" the interfaces between particles, resulting in a continuous, transparent medium.

Understanding the Trade-offs

The Pressure Threshold

Success in this process is binary regarding pressure application.

If the press fails to maintain the high pressure threshold (e.g., 175 MPa), the necessary plastic deformation will not occur. Without this deformation, mass transport is insufficient, resulting in a porous, opaque material rather than a transparent ceramic.

Uniaxial Limitations

The press applies force in a single direction (uniaxial).

While effective for flat tablets, this method relies heavily on the even distribution of force. Any inconsistency in the pressure application can lead to density gradients, potentially causing localized defects or varying levels of transparency across the sample.

Making the Right Choice for Your Goal

To optimize the cold sintering process for CaF2 ceramics, consider the following regarding the press function:

- If your primary focus is optical transparency: Ensure the press can consistently sustain high pressures (175 MPa) to maximize plastic deformation and eliminate light-scattering pores.

- If your primary focus is low-temperature processing: Rely on the press's mechanical force to compensate for the reduced thermal energy, ensuring densification occurs without requiring high heat.

The flat tablet press is not merely a shaping tool; it is the active driver of the densification physics that makes low-temperature transparency possible.

Summary Table:

| Feature | Function in CSP (CaF2 Ceramics) | Impact on Final Product |

|---|---|---|

| Uniaxial Pressure | Applies ~175 MPa to drive mechanical densification | Eliminates voids and ensures transparency |

| Plastic Deformation | Forces nanoparticle shape alteration | Overcomes material resistance to compaction |

| Particle Rearrangement | Shifts and rotates nanoparticles | Creates a tightly packed, pore-free structure |

| Mass Transport | Moves matter to particle neck regions | Heals interfaces to form a continuous medium |

Elevate Your Material Research with KINTEK

Are you looking to master the Cold Sintering Process (CSP)? KINTEK provides high-precision flat tablet presses and heating molds designed to sustain the rigorous pressure requirements needed for CaF2-based transparent ceramics.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab solutions, including:

- Muffle, Tube, Rotary, and Vacuum Systems

- CVD Systems

- Fully Customizable High-Temp Furnaces

Our equipment is engineered to ensure consistent pressure distribution and thermal control, helping you eliminate density gradients and achieve superior optical transparency. Contact us today to discuss your unique laboratory needs and discover how our customizable sintering solutions can drive your next breakthrough.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How do you maintain a heat press machine? A Proactive Guide to Consistent Prints & Longevity

- How does temperature precision in hot-pressing furnaces affect Pr3+:(Ca0.97Gd0.03)F2.03 ceramic microstructure?

- What is the core processing value of a vacuum hot pressing sintering furnace? Master AZ31 Magnesium Alloy Density

- What are the size variations available for hot press furnaces? Choose the Right Size for Your Lab or Production Needs

- What core functions do graphite molds serve? Essential Roles in Vacuum Hot Pressing Sintering of SiC/ZTA Ceramics

- How do graphite molds function during the SPS of Ti-6Al-4Zr-4Nb alloys? Mastering Dual-Action Sintering

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies

- What is the core technology behind vacuum press in metalworking industries? Unlock Precision Metal Forming