Precise temperature control is the single most critical variable determining the optical and structural integrity of Pr3+:(Ca0.97Gd0.03)F2.03 ceramics.

It acts as the regulator for atomic behavior, directly dictating whether the material achieves full densification with fine grains or suffers from transparency-killing defects.

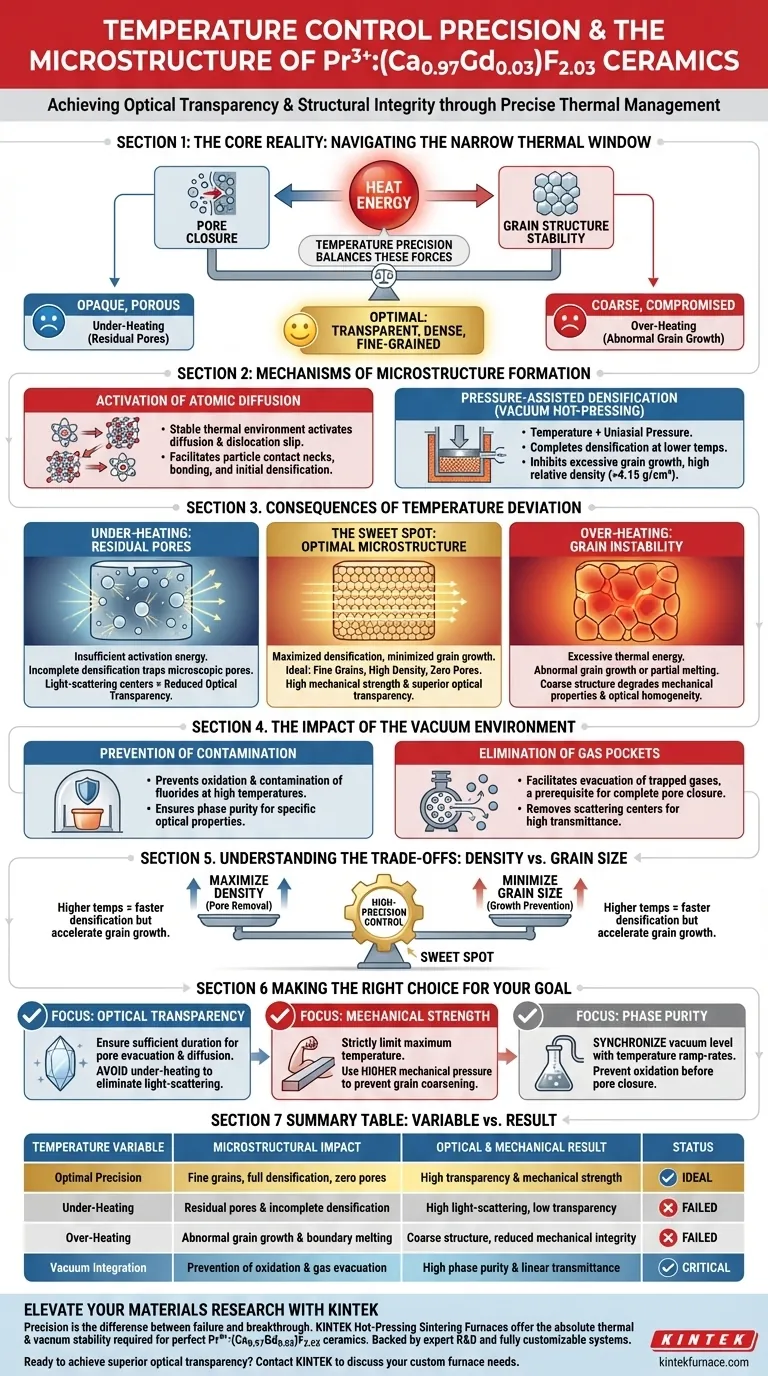

The Core Reality Achieving a perfect microstructure requires navigating a narrow thermal window. Temperature precision balances the energy needed to close pores against the risk of destabilizing the grain structure; failing to maintain this balance results in either opaque, porous material or coarse, structurally compromised ceramics.

The Mechanisms of Microstructure Formation

Activation of Atomic Diffusion

High-precision temperature control provides the stable thermal environment necessary to activate atomic diffusion and dislocation slip.

This thermal energy is required to form Shockley partial dislocations and stacking faults. These defects are essential mechanisms that dominate the initial growth of particle contact necks, facilitating the material's ability to bond and densify.

The Role of Pressure-Assisted Densification

In a vacuum hot-pressing furnace, temperature does not work alone; it works in tandem with uniaxial mechanical pressure.

This combination allows the densification process to complete rapidly at lower temperatures than would be possible with heat alone. By enabling densification at lower thermal thresholds, the process effectively inhibits excessive grain growth while ensuring high relative density (potentially exceeding 4.15 g/cm³).

Consequences of Temperature Deviation

The Risk of Under-Heating (Residual Pores)

If the temperature is maintained below the optimal window, the activation energy supplied is insufficient to complete the sintering process.

The immediate result is incomplete densification. This leaves residual pores trapped within the ceramic matrix.

These microscopic pores act as light-scattering centers. For a transparent ceramic like Pr3+:(Ca0.97Gd0.03)F2.03, this is catastrophic, as it significantly reduces optical transparency and lowers the material's transmission quality.

The Risk of Over-Heating (Grain Instability)

Conversely, exceeding the optimal temperature threshold introduces excessive thermal energy into the system.

This leads to abnormal grain growth or even partial melting of the grain boundaries. While the material may be dense, the coarse grain structure degrades mechanical properties and potentially alters the optical homogeneity of the ceramic.

The Impact of the Vacuum Environment

Prevention of Contamination

Precise control of the vacuum environment during heating prevents the oxidation or contamination of the fluoride materials.

At high sintering temperatures, fluorides are susceptible to reacting with the atmosphere. A high vacuum ensures phase purity, which is fundamental for maintaining the specific optical properties of the Pr3+ dopant.

Elimination of Gas Pockets

The vacuum facilitates the evacuation of gases trapped within microscopic pores.

Removing these gases is a prerequisite for closing the pores completely. This elimination of gas-filled voids is critical for removing scattering centers, thereby ensuring high linear transmittance in both visible and near-infrared spectral regions.

Understanding the Trade-offs

The Density vs. Grain Size Conflict

The central challenge in hot-pressing is the trade-off between maximizing density and minimizing grain size.

Higher temperatures generally promote faster densification (removing pores) but simultaneously accelerate grain growth.

The "Sweet Spot" Strategy

The goal of high-precision control is to hit the exact "sweet spot" where densification is maximized, but grain boundary migration (growth) is minimized.

This results in the ideal microstructure: fine grains, high density, and zero pores. This specific configuration is what yields high mechanical strength and superior optical transparency.

Making the Right Choice for Your Goal

To optimize the Pr3+:(Ca0.97Gd0.03)F2.03 ceramic production, you must tailor your thermal profile to your specific performance requirements:

- If your primary focus is Optical Transparency: Prioritize a temperature profile that ensures sufficient duration for pore evacuation and diffusion, avoiding even slight under-heating to eliminate light-scattering centers.

- If your primary focus is Mechanical Strength: Strictly limit the maximum temperature and utilize higher mechanical pressure to achieve density, preventing the grain coarsening that weakens the material.

- If your primary focus is Phase Purity: Ensure the vacuum level is synchronized with temperature ramp-rates to prevent oxidation before pore closure occurs.

Ultimately, the transparency of your ceramic is a direct reflection of the stability and precision of your furnace's temperature control system.

Summary Table:

| Temperature Variable | Microstructural Impact | Optical & Mechanical Result |

|---|---|---|

| Optimal Precision | Fine grains, full densification, zero pores | High transparency & mechanical strength |

| Under-Heating | Residual pores & incomplete densification | High light-scattering, low transparency |

| Over-Heating | Abnormal grain growth & boundary melting | Coarse structure, reduced mechanical integrity |

| Vacuum Integration | Prevention of oxidation & gas evacuation | High phase purity & linear transmittance |

Elevate Your Materials Research with KINTEK

Precision is the difference between a failed sample and a breakthrough. At KINTEK, we understand that achieving the perfect "sweet spot" for Pr3+:(Ca0.97Gd0.03)F2.03 ceramics requires absolute thermal and vacuum stability.

Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized Hot-Pressing Sintering furnaces. Our systems are fully customizable to your unique research needs, ensuring you maintain the exact temperature profiles required to eliminate pores and control grain growth.

Ready to achieve superior optical transparency?

Contact KINTEK today to discuss your custom furnace needs

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- How does a Vacuum Hot Pressing (VHP) furnace prepare high-performance P-type Mg3Sb2 thermoelectric materials?

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- How does a vacuum hot press furnace contribute to the fabrication of ZnS infrared ceramics? Optimize Optical Quality

- What is the primary role of mechanical pressure in Ti-Al vacuum hot pressing? Optimize Bonding and Density

- Why is graphite mold interaction critical for ZnS ceramics? Protect Your Optical Purity in Vacuum Hot Pressing

- What role does a hot press sintering furnace play in Cf-UHTC production? Achieve Peak Density in Refractory Composites