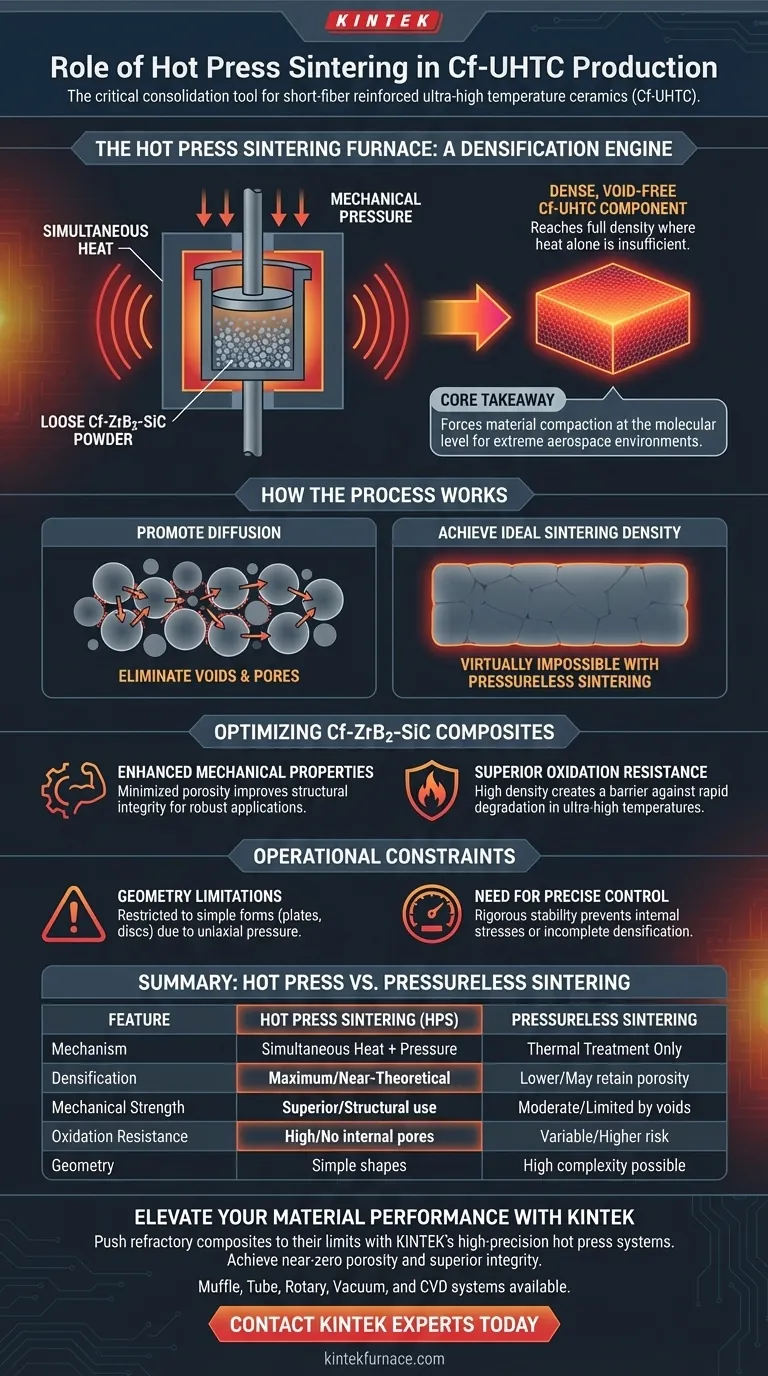

The hot press sintering furnace acts as the critical consolidation tool in the manufacturing of short-fiber reinforced ultra-high temperature ceramics (Cf-UHTC), specifically Cf-ZrB2-SiC composites. It functions by creating a strictly controlled environment that applies simultaneous high temperature and mechanical pressure to ceramic powders, driving the material to reach full density where heat alone would be insufficient.

Core Takeaway While standard furnaces only apply heat, a hot press sintering furnace uses physical pressure to force material compaction at the molecular level. This dual-action process is essential for transforming loose Cf-ZrB2-SiC powders into dense, oxidation-resistant components capable of surviving extreme aerospace environments.

How the Process Works

The production of high-performance ceramics requires more than simple thermal treatment. The hot press furnace addresses the specific physical challenges of sintering complex composites.

Simultaneous Heat and Pressure

The defining feature of this equipment is its ability to apply heat and pressure at the same time.

While the high temperature softens the material, the mechanical pressure forces the particles together.

Promoting Diffusion and Densification

For distinct ceramic powder particles to become a solid mass, atoms must move across particle boundaries.

The furnace promotes this diffusion, effectively eliminating voids and pores between particles. This ensures the material achieves an ideal sintering density, which is virtually impossible to achieve with pressureless sintering for these specific materials.

Optimizing Cf-ZrB2-SiC Composites

The primary reference highlights the specific application of this furnace for Cf-ZrB2-SiC (Carbon fiber reinforced Zirconium Diboride-Silicon Carbide) materials.

Enhancing Mechanical Properties

By minimizing porosity through pressure, the furnace significantly improves the structural integrity of the composite.

The resulting material exhibits superior mechanical properties, making it robust enough for structural applications rather than just thermal insulation.

Ensuring Oxidation Resistance

In ultra-high temperature environments, any internal porosity can lead to rapid material degradation.

The high density achieved via hot pressing creates a barrier that grants the composite superior oxidation resistance. This is a prerequisite for materials intended for re-entry vehicles or hypersonic flight.

Understanding the Operational Constraints

While the hot press furnace is vital for performance, it introduces specific operational factors that must be managed.

Geometry Limitations

Unlike pressureless sintering or muffle furnaces, which can process complex shapes, hot pressing typically restricts component geometry to simpler forms (plates or discs) due to the uniaxial pressure application.

The Need for Precise Control

The primary benefit of this furnace is the "controlled environment."

Deviations in either pressure or temperature curves can lead to internal stresses or incomplete densification. The equipment must maintain rigorous stability to ensure the "ideal" density mentioned in technical specifications is actually reached.

Making the Right Choice for Your Goal

To determine if this specific sintering technology aligns with your manufacturing requirements, consider the following technical priorities:

- If your primary focus is Maximum Density and Strength: You must use a hot press sintering furnace, as simultaneous pressure is required to eliminate voids in refractory ceramics like ZrB2-SiC.

- If your primary focus is Complex Geometry: You may need to explore pressureless sintering techniques, accepting that you will likely sacrifice some density and mechanical strength compared to hot-pressed parts.

The hot press sintering furnace is not merely a heater; it is a densification engine designed to push refractory composites to their theoretical performance limits.

Summary Table:

| Feature | Hot Press Sintering (HPS) | Pressureless Sintering |

|---|---|---|

| Mechanism | Simultaneous Heat + Mechanical Pressure | Thermal Treatment Only |

| Densification | Maximum (Near-Theoretical Density) | Lower (May retain porosity) |

| Mechanical Strength | Superior; ideal for structural use | Moderate; often limited by voids |

| Oxidation Resistance | High; due to lack of internal pores | Variable; higher risk of degradation |

| Geometry Complexity | Simple shapes (plates, discs) | High complexity possible |

Elevate Your Material Performance with KINTEK

Ready to push your refractory composites to their theoretical limits? KINTEK’s high-precision hot press sintering systems provide the rigorous temperature and uniaxial pressure control necessary to achieve near-zero porosity and superior mechanical integrity in Cf-UHTC production.

Backed by expert R&D and world-class manufacturing, KINTEK offers a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or industrial needs. Don't compromise on density or durability—partner with the leaders in high-temperature technology.

Contact KINTEK Experts Today to discuss your custom furnace requirements.

Visual Guide

References

- Sirui Gong, Yukui Wang. Methodology for Surface Reconstruction and Prediction Based on the Electrical Discharge Machining Removal Mechanism of Cf-UHTC Materials. DOI: 10.3390/ma18020371

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the working principle of a vacuum hot press sintering furnace? Master Dense Material Creation

- Why is a high vacuum required in a hot-pressing furnace? Achieve Perfect Transparency in Fluoride Ceramics

- What applications does Vacuum Hot Press technology have in the electronics and semiconductor industry? Unlock High-Performance Component Manufacturing

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- Why is a high vacuum environment crucial when preparing copper-carbon nanotube composites in a vacuum hot press furnace? Achieve Superior Composite Integrity

- What are the technical advantages of using a Spark Plasma Sintering (SPS) system for Barium Titanate ceramics?

- Why are Carbon Fiber Reinforced Composite (CFRC) plates used in SPS? Optimize Thermal Stability in Sintering

- What are the key advantages of vacuum hot press furnaces compared to conventional furnaces? Achieve Superior Purity and Control