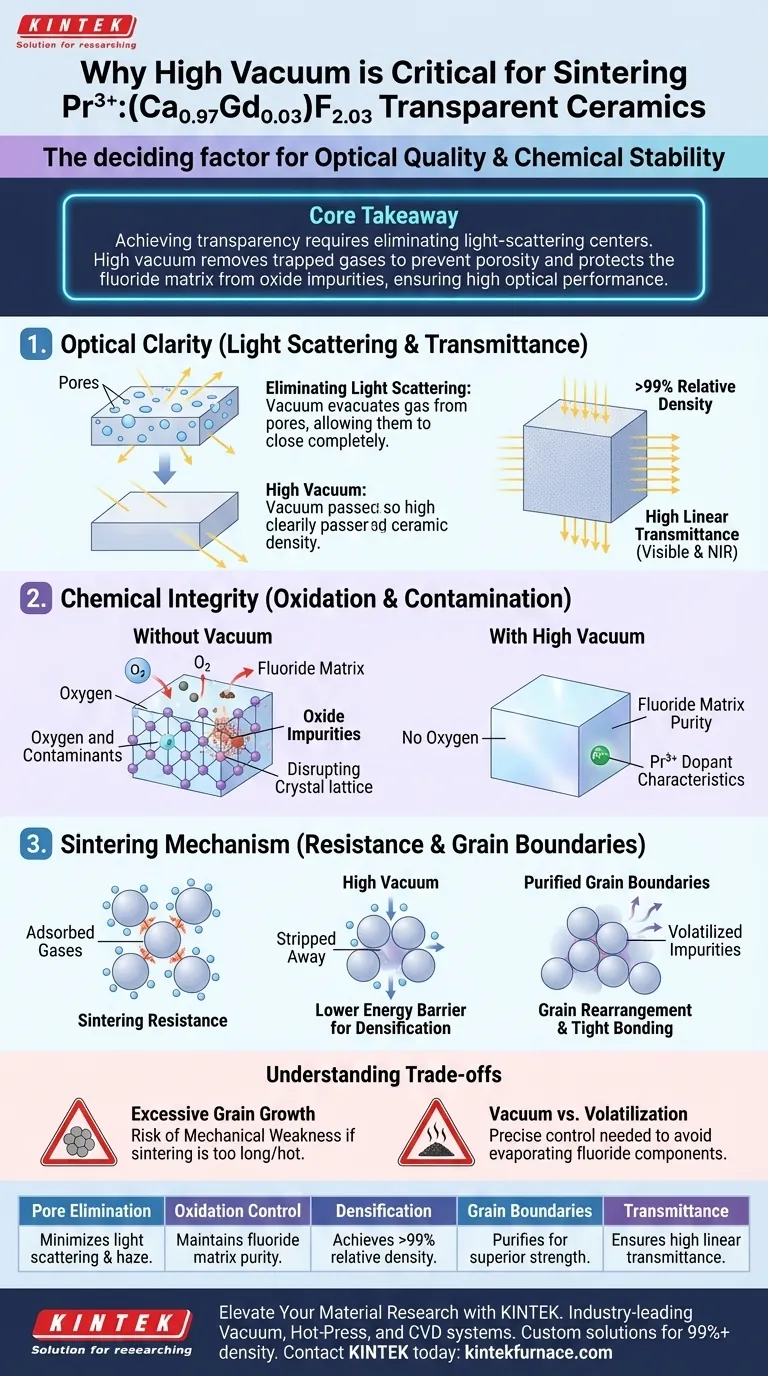

A high vacuum environment is critical for ensuring the optical quality and chemical stability of Pr3+:(Ca0.97Gd0.03)F2.03 transparent ceramics. Primarily, it prevents the oxidation of the fluoride matrix at high temperatures and actively evacuates gases from microscopic pores, which is the deciding factor in achieving high transparency.

Core Takeaway Achieving transparency in ceramics requires the near-total elimination of light-scattering centers. A high vacuum is the primary mechanism for removing trapped gases that cause porosity, while simultaneously protecting the material from forming oxide impurities that degrade optical performance.

The Critical Role of Vacuum in Optical Clarity

Eliminating Light Scattering Centers

The most significant barrier to transparency in ceramics is light scattering. Even microscopic residual pores act as scattering centers, causing the material to appear opaque or hazy.

A high vacuum environment creates a pressure differential that draws gases out of these tiny pores. By evacuating this gas, the vacuum allows the pores to close completely during the sintering process.

Achieving High Linear Transmittance

For applications requiring operation in the visible and near-infrared spectral regions, the material must be dense.

The removal of pore-filling gases ensures the final ceramic reaches a high relative density (often exceeding 99%). This high density is directly responsible for the material's high linear transmittance.

Preserving Chemical Integrity

Preventing High-Temperature Oxidation

Fluoride materials are chemically sensitive, particularly when subjected to the heat required for sintering.

Without a vacuum, oxygen present in the atmosphere would react with the fluoride matrix. This oxidation creates oxide impurities, which disrupt the crystal lattice and degrade the intrinsic properties of the Pr3+:(Ca0.97Gd0.03)F2.03 compound.

Avoiding Contamination

Beyond simple oxidation, a high vacuum eliminates other atmospheric contaminants.

By maintaining a pristine environment, the furnace ensures that the chemical composition of the ceramic remains pure. This purity is essential for maintaining the specific optical characteristics of the praseodymium (Pr3+) dopant.

Enhancing the Sintering Mechanism

Reducing Sintering Resistance

Powder particles naturally adsorb gases on their surfaces. If these gases are not removed, they create resistance between particles, preventing them from bonding together.

The vacuum environment strips away these adsorbed gases and any volatile byproducts generated during heating. This lowers the energy barrier for densification, allowing particles to fuse more easily.

Purifying Grain Boundaries

The interface between crystal grains—the grain boundary—must be clean for the material to be mechanically strong and optically clear.

Vacuum promotes the volatilization of surface impurities. This purification increases surface energy and creates favorable conditions for the grains to rearrange and bond tightly under the mechanical pressure of the hot press.

Understanding the Trade-offs

The Risk of Excessive Grain Growth

While vacuum aids densification, it must be balanced carefully with temperature and pressure.

If the temperature is too high or the sintering time too long under vacuum, grains may grow abnormally large. While the material may be pore-free, excessive grain growth can mechanically weaken the ceramic, even if transparency is achieved.

Vacuum vs. Volatilization

There is a delicate balance when sintering fluorides. While vacuum prevents oxidation, extremely high vacuums at peak temperatures can sometimes lead to the volatilization of the fluoride components themselves.

Precise control is required to remove impurities without evaporating the matrix material, which would alter the stoichiometry (chemical ratio) of the ceramic.

Making the Right Choice for Your Goal

To optimize the sintering of Pr3+:(Ca0.97Gd0.03)F2.03, prioritize your parameters based on the specific defect you are trying to eliminate:

- If your primary focus is eliminating haze (scattering): Prioritize the depth of the vacuum during the initial heating stages to ensure maximum evacuation of trapped gases before pores seal off.

- If your primary focus is chemical purity: Ensure the vacuum is established well before the temperature reaches the oxidation threshold of the fluoride components.

- If your primary focus is mechanical strength: Balance the vacuum with precise mechanical pressure (e.g., hot pressing) to maximize density while keeping grain size fine.

Ultimately, the vacuum is not just a protective measure; it is an active processing tool that physically extracts the defects that stand between opacity and transparency.

Summary Table:

| Feature | Impact on Pr3+:(Ca0.97Gd0.03)F2.03 Ceramics |

|---|---|

| Pore Elimination | Removes trapped gases to minimize light scattering and haze. |

| Oxidation Control | Prevents oxygen reactions to maintain fluoride matrix purity. |

| Densification | Lowers sintering resistance to achieve >99% relative density. |

| Grain Boundaries | Purifies interfaces for superior mechanical and optical strength. |

| Transmittance | Ensures high linear transmittance in visible and NIR regions. |

Elevate Your Material Research with KINTEK

Precision sintering requires uncompromising atmosphere control. KINTEK provides industry-leading Vacuum, Hot-Press, and CVD systems designed to eliminate light-scattering defects and prevent high-temperature oxidation in sensitive fluoride ceramics.

Backed by expert R&D and precision manufacturing, our lab high-temperature furnaces are fully customizable to meet your unique chemical and optical specifications.

Ready to achieve 99%+ relative density in your ceramic samples?

Contact KINTEK today for a custom furnace solution.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the advantages of SPS vs Hot Pressing for Ti-6Al-4V/HA? Maximize Bioactivity with Rapid Sintering

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- How does a Vacuum Hot Pressing (VHP) furnace facilitate the preparation of highly dense Mg3Sb2? Expert Densification

- What advantages does vacuum press technology offer in metal shaping processes? Achieve Precision and Efficiency in Metal Forming

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing

- What are the process advantages of using SPS for protonic ceramic electrolytes? Achieve Rapid Densification

- What are the core functions of a vacuum hot pressing furnace in the densification of Cr2AlC ceramics?

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies