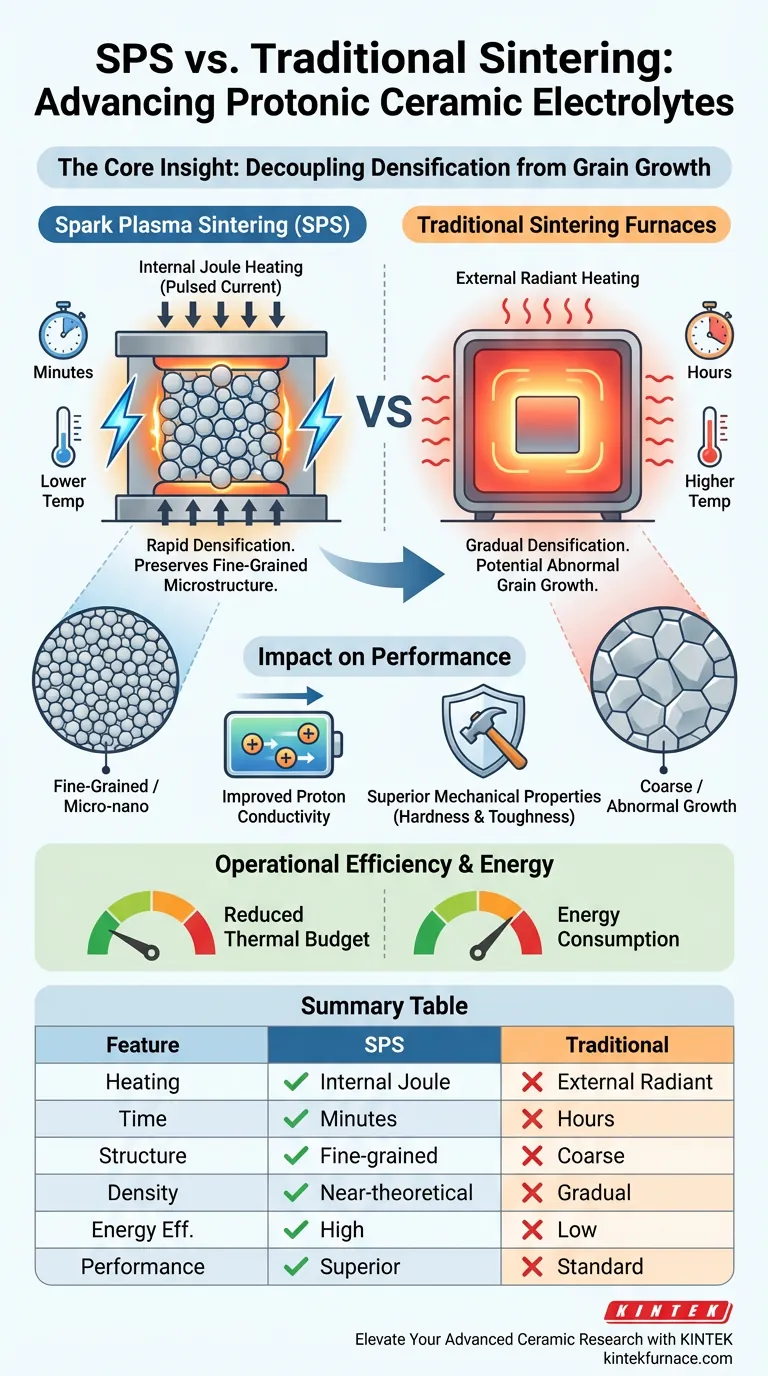

Spark Plasma Sintering (SPS) offers a distinct processing advantage by utilizing high-voltage pulsed current to generate internal heat and pressure simultaneously. Unlike traditional external heating methods, this allows protonic ceramic electrolytes to achieve rapid densification at significantly lower temperatures.

The Core Insight: The defining characteristic of SPS is its ability to decouple densification from grain growth. By achieving full density in minutes rather than hours, the process preserves a fine-grained microstructure, which is critical for maximizing both the mechanical integrity and the proton conductivity of the electrolyte.

The Mechanism of Rapid Densification

Internal Joule Heating

Traditional furnaces rely on radiant heat transfer from the outside in. In contrast, SPS applies pulsed current directly to the sample and mold. This generates Joule heating and plasma discharge between particles, creating immediate internal heat.

Simultaneous Pressure Application

SPS integrates synchronous mechanical pressure during the heating phase. This provides an additional driving force for sintering, allowing the material to reach near-theoretical density through particle rearrangement and plastic flow much faster than pressureless methods.

Localized Activation

The pulsed current causes temperatures at the specific contact points between particles to spike significantly higher than the overall sample temperature. This localized energy facilitates particle bonding (or liquid phase formation) without requiring the entire bulk material to reach excessive thermal extremes.

Impact on Microstructure and Performance

Inhibition of Grain Growth

Because the heating rate is extremely high and the holding time is very short, the window for grain coarsening is minimized. Traditional sintering often leads to abnormal grain growth due to prolonged high-temperature exposure, but SPS effectively "freezes" the fine grain structure in place.

Isotropic Fine-Grained Structure

The result is a ceramic with an isotropic micro-nano fine grain structure. For protonic electrolytes, this structural uniformity is vital for consistent performance across the material.

Enhanced Electrolyte Properties

The primary reference indicates a direct correlation between this fine-grained structure and performance. A dense electrolyte produced via SPS exhibits improved proton conductivity alongside superior mechanical properties, such as hardness and fracture toughness.

Operational Efficiency and Energy

Reduced Thermal Budget

The rapid heating mechanism significantly lowers the overall bulk sintering temperature required to densify the ceramic. This reduction in thermal budget prevents the degradation of volatile components often found in complex ceramic chemistries.

Energy Consumption

Compared to traditional pressureless sintering, SPS substantially reduces energy consumption. The process eliminates the need for long ramp-up and cool-down cycles, focusing energy only where and when it is needed.

Understanding the Process Nuances

Temperature Gradients

While the bulk temperature remains low, the local temperature at particle contact points is extreme. Users must understand that the "measured" temperature of the mold may differ from the microscopic temperature at the particle interface, which drives the sintering physics.

Making the Right Choice for Your Goal

If you are developing protonic ceramic electrolytes, the choice between SPS and traditional methods depends on your specific performance targets:

- If your primary focus is Conductivity and Strength: Choose SPS to achieve a high-density, fine-grained structure that maximizes proton transport and fracture toughness.

- If your primary focus is Processing Speed: Choose SPS to leverage rapid heating rates and short holding times, reducing cycle times from hours to minutes.

- If your primary focus is Material Stability: Choose SPS to sinter at lower bulk temperatures, minimizing the risk of volatilization or abnormal grain growth.

SPS provides a high-precision pathway to producing robust, highly conductive electrolytes that traditional thermal cycling simply cannot replicate.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Sintering Furnaces |

|---|---|---|

| Heating Mechanism | Internal Joule Heating (Pulsed Current) | External Radiant Heating |

| Sintering Time | Minutes | Hours |

| Grain Structure | Fine-grained / Micro-nano (Inhibited growth) | Coarse / Potential abnormal growth |

| Density | Near-theoretical (Rapidly achieved) | Gradual densification |

| Energy Efficiency | High (Low thermal budget) | Low (Long ramp-up/cool-down) |

| Key Performance | Superior conductivity & toughness | Standard mechanical/electrical properties |

Elevate Your Advanced Ceramic Research with KINTEK

Unlock the full potential of your protonic ceramic electrolytes with KINTEK’s high-precision sintering solutions. Backed by expert R&D and manufacturing, we offer customizable Spark Plasma Sintering (SPS), Vacuum, CVD systems, and Muffle furnaces tailored to your unique research needs. Whether you are aiming for superior proton conductivity or optimized mechanical integrity, our systems provide the control and efficiency required for next-generation material science.

Ready to transform your lab's capabilities? Contact KINTEK today to find the perfect high-temperature furnace for your application.

Visual Guide

References

- Mengyang Yu, Shenglong Mu. Recent Novel Fabrication Techniques for Proton-Conducting Solid Oxide Fuel Cells. DOI: 10.3390/cryst14030225

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the core advantages of using a vacuum hot press furnace? Achieve Near-Forged Density for Ti-6Al-4V Alloys

- Why is a vacuum hot press furnace required for sintering CNT-Al composites? Optimize Density and Interface Bonding

- Why is a Vacuum Hot Pressing Sintering Furnace Essential for 6061-20IQC? Unlock High-Performance Composites

- How does precise temperature control in a vacuum hot press furnace affect Al-Si/graphite? Optimize Interface Bonding

- How does vacuum hot pressing compare to vacuum brazing and sintering? Choose the Right Process for Your Materials

- How does a Vacuum Hot Press (VHP) furnace facilitate the fabrication of bulk nanostructured Al-4Cu alloys?

- What role do specialized mold materials play in hot pressing? Optimize Your Process with the Right Choice

- What control features does a vacuum hot press furnace offer? Precision Control for Advanced Materials Processing