In hot pressing, specialized mold materials serve as the core enabler of the process. These materials are not merely containers; they are active components engineered to withstand extreme temperatures and pressures while directly shaping the final part's geometry and quality. Their role is to ensure the integrity of the manufacturing cycle and influence the final properties of the consolidated material.

The selection of a mold material is a strategic engineering decision, not just an operational one. The choice between materials like graphite and superalloys dictates the process's efficiency, cost-effectiveness, and the ultimate performance characteristics of the manufactured component.

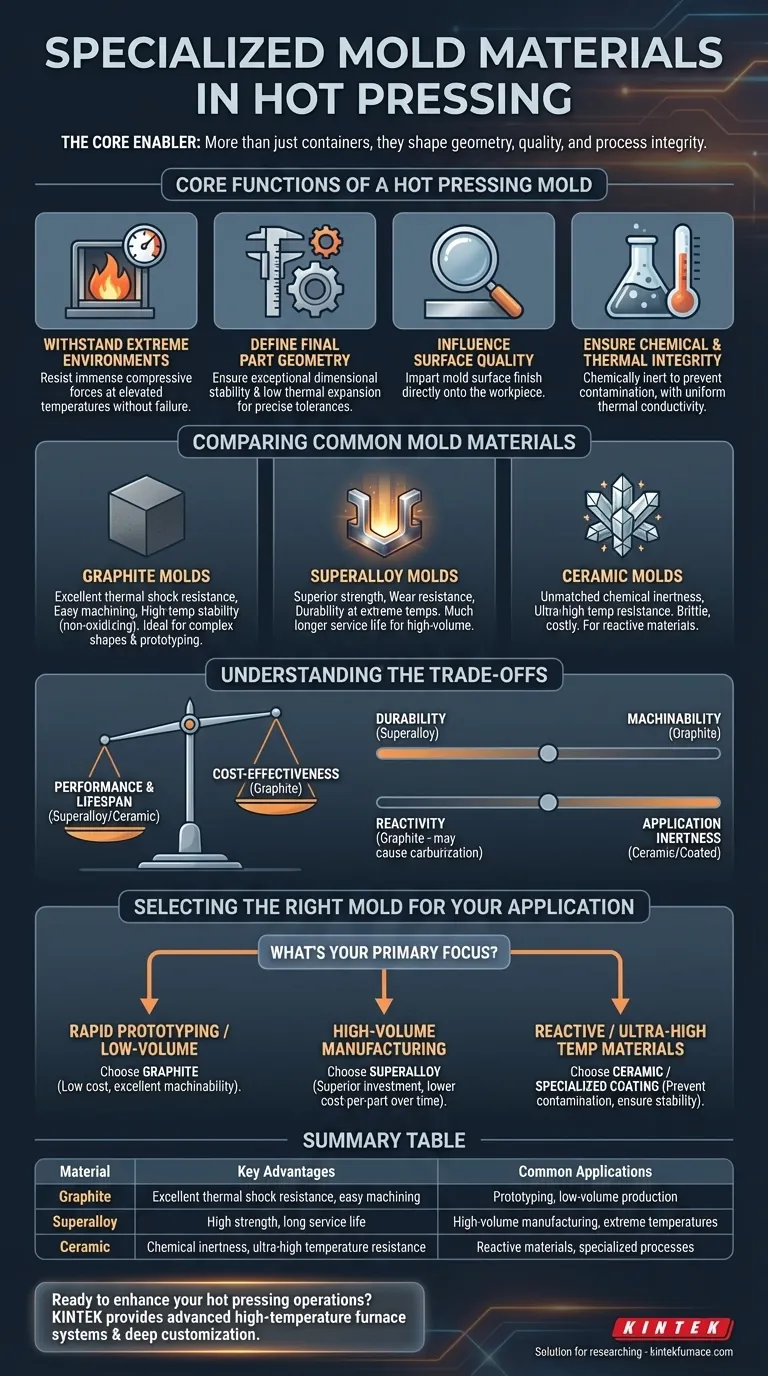

The Core Functions of a Hot Pressing Mold

A mold in a hot pressing operation must perform several critical functions simultaneously under some of the most demanding manufacturing conditions.

Withstanding Extreme Environments

The primary requirement is survival. Mold materials must possess high strength at elevated temperatures to resist the immense compressive forces applied during pressing without deforming, cracking, or failing.

Defining Final Part Geometry

The mold provides the net shape for the final component. Therefore, it must exhibit exceptional dimensional stability and low thermal expansion to ensure the finished part meets precise geometric tolerances after cooling.

Influencing Surface Quality

The surface of the mold is directly imparted onto the workpiece. A mold with a fine, polished surface will produce a part with a smooth finish, potentially reducing the need for secondary machining or finishing operations.

Ensuring Chemical and Thermal Integrity

A mold must be chemically inert with respect to the workpiece material to prevent unwanted reactions or contamination. Furthermore, its thermal conductivity is critical for ensuring uniform heating and cooling, which prevents internal stresses and defects in the final part.

Comparing Common Mold Materials

The choice of material is driven by the specific demands of the application, including the processing temperature, pressure, and the material being pressed.

Graphite Molds

Graphite is a common choice due to its excellent thermal shock resistance, high-temperature stability (in non-oxidizing atmospheres), and relative ease of machining. This makes it ideal for complex shapes and prototyping.

Superalloy Molds

Materials like nickel-based superalloys (e.g., Inconel) or refractory metals (e.g., molybdenum) offer superior strength, wear resistance, and durability at extreme temperatures. They provide a much longer service life than graphite in high-volume production environments.

Ceramic Molds

For ultra-high-temperature applications or when processing highly reactive materials, advanced ceramic molds (like silicon carbide or alumina) may be used. They offer unmatched chemical inertness and temperature resistance but are often more brittle and costly.

Understanding the Trade-offs

Selecting a mold material always involves balancing competing factors. Understanding these trade-offs is key to optimizing your process.

Performance vs. Cost

Superalloy and ceramic molds offer superior performance and lifespan but come with a significantly higher initial cost. Graphite is a cost-effective solution, especially for lower-volume runs or when frequent design changes are expected.

Durability vs. Machinability

The exceptional hardness that gives superalloys their durability also makes them difficult and expensive to machine. Graphite's relative softness makes it easy to shape into intricate geometries, accelerating development cycles.

Reactivity vs. Application

While often considered inert, graphite molds can lead to carbon contamination in certain alloys, a phenomenon known as carburization. In such cases, a metallic or ceramic mold—or a graphite mold with a protective ceramic coating—is essential to maintain the purity of the workpiece.

Selecting the Right Mold for Your Application

Your choice should be directly aligned with your project's primary objective.

- If your primary focus is rapid prototyping or low-volume production: Graphite is often the most practical choice due to its low cost and excellent machinability.

- If your primary focus is high-volume manufacturing and long-term durability: Superalloy molds are the superior investment, providing a lower cost-per-part over the tool's extended life.

- If your primary focus is processing highly reactive or ultra-high-temperature materials: A ceramic mold or a specialized coating is necessary to prevent contamination and ensure process stability.

Ultimately, the mold is not a passive tool but an active and critical component that defines the boundaries of what is possible in your hot pressing operation.

Summary Table:

| Material | Key Advantages | Common Applications |

|---|---|---|

| Graphite | Excellent thermal shock resistance, easy machining | Prototyping, low-volume production |

| Superalloy | High strength, long service life | High-volume manufacturing, extreme temperatures |

| Ceramic | Chemical inertness, ultra-high temperature resistance | Reactive materials, specialized processes |

Ready to enhance your hot pressing operations with tailored mold solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs—contact us today via our contact form to discuss how we can optimize your process efficiency and part quality!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What is a vacuum hot press furnace? Unlock Superior Material Performance