At their core, vacuum hot pressing, vacuum brazing, and vacuum sintering are fundamentally different manufacturing processes designed to achieve distinct goals. Vacuum brazing is a joining process that uses a filler metal to bond solid components together. In contrast, both vacuum sintering and vacuum hot pressing create a solid part from a powder, but hot pressing adds external pressure to force densification, whereas sintering relies on heat alone.

The critical distinction lies in the desired outcome and the mechanism used to achieve it. Your choice depends entirely on whether you need to join components, consolidate a powder with heat, or compress a powder with heat and force to achieve maximum density.

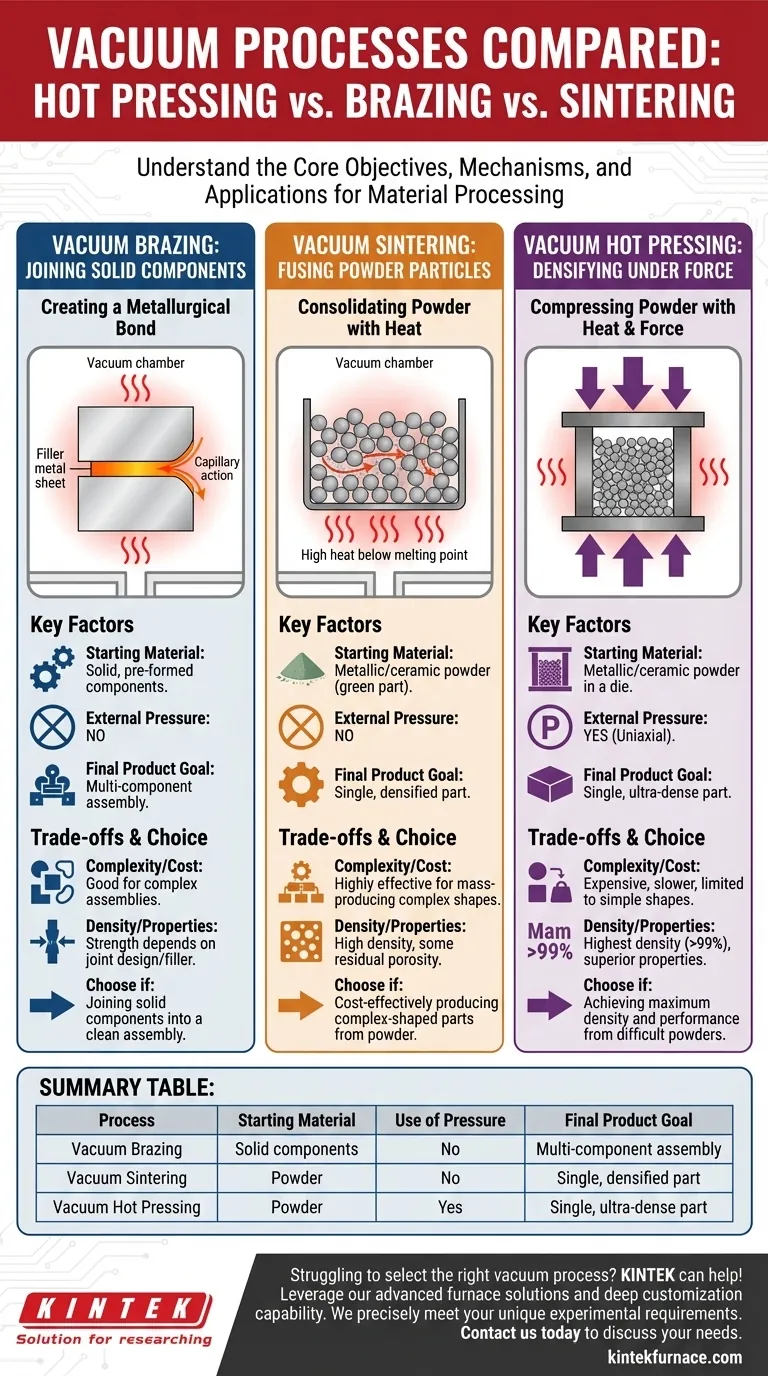

Understanding the Core Objective of Each Process

While all three processes operate in a vacuum to prevent oxidation and contamination, their purposes do not overlap. Each manipulates materials at a granular or atomic level in a unique way.

Vacuum Brazing: Creating a Metallurgical Bond

Vacuum brazing is a joining technique. Its sole purpose is to connect two or more separate, solid parts into a single assembly.

The process involves placing a filler metal, which has a lower melting point than the base components, at the joint. When heated in a vacuum, this filler metal melts, flows into the gap via capillary action, and solidifies upon cooling, creating a strong, permanent, and often seamless bond.

Vacuum Sintering: Fusing Powder Particles Together

Vacuum sintering is a powder metallurgy process used to create solid objects from a powdered material without melting it.

A "green" part, which is a loosely compacted powder, is heated to a high temperature below its melting point. At this temperature, atoms diffuse across the boundaries of the particles, causing them to fuse together. This process reduces porosity and causes the part to shrink and densify.

Vacuum Hot Pressing: Densifying Under Force

Vacuum hot pressing is an advanced consolidation process that combines high temperature and uniaxial pressure simultaneously. Like sintering, it starts with a powder.

However, the application of direct mechanical pressure dramatically accelerates the densification process. This force aids in particle rearrangement and plastic deformation, effectively squeezing out porosity. This is essential for materials that are very difficult to densify through sintering alone.

Key Differentiating Factors

The choice between these methods becomes clear when you analyze three key factors: the use of pressure, the starting material, and the final product's objective.

The Role of External Pressure

This is the most important distinction. Vacuum hot pressing is the only process of the three that uses external, mechanical pressure.

Sintering relies only on thermal energy to drive atomic diffusion. Brazing relies on capillary action to distribute a molten filler. The pressure in hot pressing overcomes the material's resistance to densification, making it ideal for high-performance applications.

Starting Material Form

The state of the material at the beginning of the process dictates the method.

- Vacuum Brazing: Starts with two or more solid, pre-formed components.

- Vacuum Sintering: Starts with a metallic or ceramic powder, often pre-formed into a shape.

- Vacuum Hot Pressing: Starts with a metallic or ceramic powder placed inside a die.

The Final Product's Goal

The intended function of the final product is a clear indicator of the required process.

- Brazing results in a multi-component assembly (e.g., a turbine blade joined to a disc).

- Sintering results in a single, densified part created from a powder (e.g., a gear or a medical implant).

- Hot Pressing results in a single, ultra-dense part created from a powder (e.g., a block of advanced ceramic or a sputtering target).

Understanding the Trade-offs

Each process comes with its own set of advantages and limitations related to cost, complexity, and performance.

Geometric Complexity and Cost

Vacuum sintering is highly effective for mass-producing complex, near-net-shape parts, which minimizes post-processing and cost at scale.

Vacuum hot pressing is typically more expensive and much slower. Because pressure is applied along a single axis, it is generally limited to producing simple shapes like discs, blocks, and cylinders.

Achievable Density and Properties

Vacuum hot pressing consistently achieves the highest final densities, often exceeding 99% of the material's theoretical density. This lack of porosity leads to superior mechanical properties like strength and hardness.

While vacuum sintering can produce highly dense parts, some residual porosity is common. The strength of a brazed joint is entirely dependent on the joint design and the properties of the filler metal.

How to Choose the Right Process

Your decision should be guided by the specific engineering requirement you need to fulfill.

- If your primary focus is joining solid components into a clean, strong assembly: Vacuum brazing is the correct and only choice for this task.

- If your primary focus is cost-effectively producing complex-shaped parts from a powder: Vacuum sintering is the industry standard for this goal.

- If your primary focus is achieving maximum density and mechanical performance from a powder, especially with difficult-to-sinter materials: Vacuum hot pressing is the necessary tool, despite its geometric limitations.

Ultimately, selecting the right thermal process is about matching the mechanism to your material and final objective.

Summary Table:

| Process | Starting Material | Use of Pressure | Final Product Goal |

|---|---|---|---|

| Vacuum Brazing | Solid components | No | Multi-component assembly |

| Vacuum Sintering | Powder | No | Single, densified part |

| Vacuum Hot Pressing | Powder | Yes | Single, ultra-dense part |

Struggling to select the right vacuum process for your materials? KINTEK can help! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether you need to join components, consolidate powders, or achieve maximum density. Contact us today to discuss how our tailored solutions can enhance your manufacturing efficiency and performance!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?