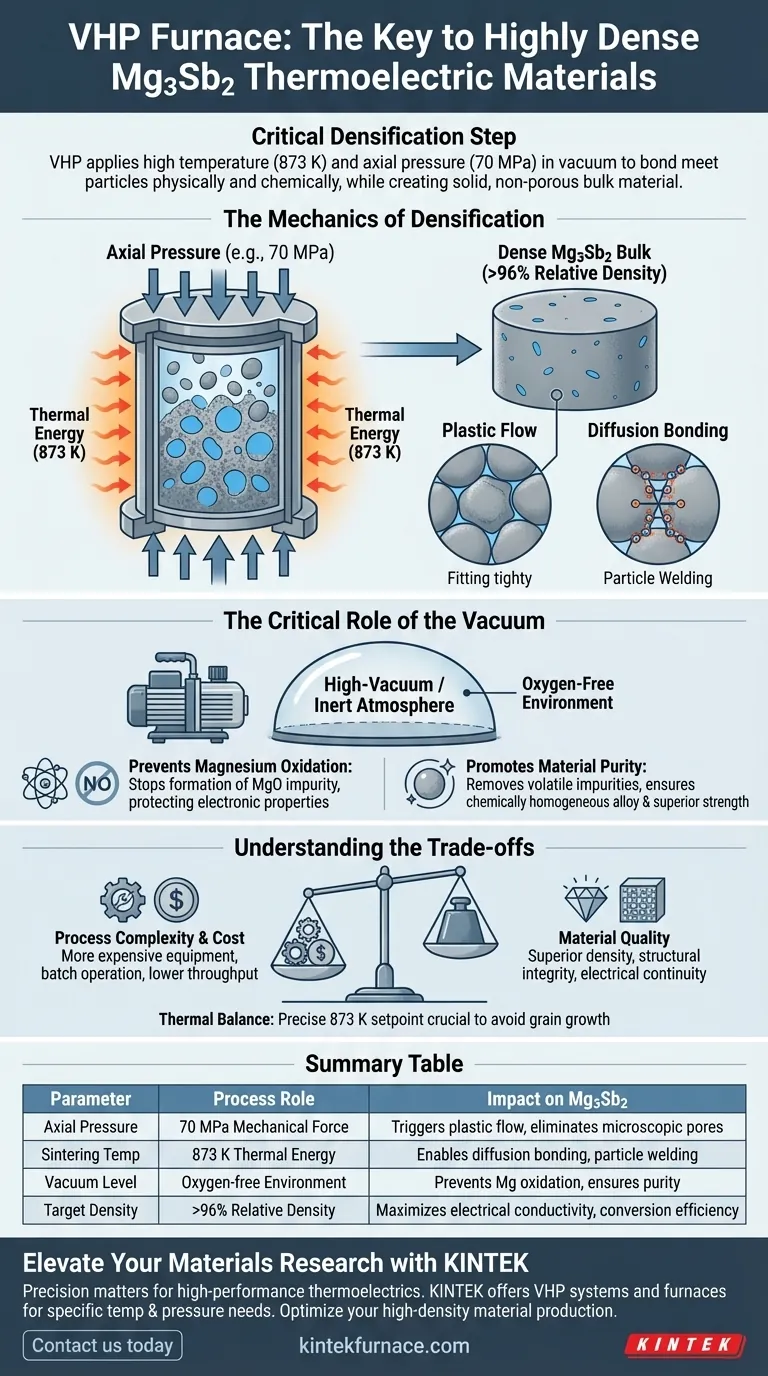

Vacuum Hot Pressing (VHP) serves as the critical densification step for creating high-performance Mg3Sb2 thermoelectric materials. By simultaneously subjecting the powder to high temperatures (typically around 873 K) and substantial axial pressure (around 70 MPa) within a vacuum, the furnace forces particles to bond physically and chemically. This dual-action process creates a solid, non-porous bulk material that standard heating methods cannot achieve.

The core advantage of VHP lies in triggering plastic flow and diffusion bonding at the particle level. This mechanism eliminates microscopic pores to achieve relative densities exceeding 96%, ensuring the material has the structural integrity and electrical continuity required for efficient thermoelectric energy conversion.

The Mechanics of Densification

Simultaneous Thermal and Mechanical Force

Standard sintering relies solely on heat to bond particles, which often leaves gaps (pores) in the material.

VHP overcomes this by applying axial pressure (e.g., 70 MPa) while the material is heated to 873 K. This combination provides the necessary activation energy to deform the solid particles, forcing them to fill voids that heat alone cannot close.

Plastic Flow and Diffusion Bonding

Under this intense heat and pressure, the Mg3Sb2 powder undergoes plastic flow.

The particles soften and physically deform to fit together tightly. Simultaneously, diffusion bonding occurs, where atoms move across the boundaries of touching particles, welding them together into a coherent solid mass.

Achieving Near-Theoretical Density

The ultimate goal of this process is to maximize density.

VHP allows the sample to reach a relative density of over 96% (near-theoretical levels). High density is non-negotiable for thermoelectrics because pores act as barriers to electron flow, drastically reducing electrical conductivity and overall efficiency.

The Critical Role of the Vacuum

Preventing Magnesium Oxidation

Magnesium (Mg) is highly reactive and prone to rapid oxidation when exposed to air, especially at high temperatures.

The VHP furnace operates in a high-vacuum or inert atmosphere. This oxygen-free environment is essential to prevent the formation of magnesium oxide (MgO), an impurity that would degrade the electronic properties of the final material.

Promoting Material Purity

Beyond preventing oxidation, the vacuum environment aids in cleaning the particle surfaces.

It helps facilitate the removal of volatile impurities and ensures that the reaction between Magnesium and Antimony (Sb) proceeds without interference from atmospheric gases. This results in a chemically homogeneous alloy with superior mechanical strength.

Understanding the Trade-offs

Process Complexity vs. Material Quality

While VHP produces superior density compared to pressureless sintering, it introduces complexity.

The equipment is more expensive and the process is generally a batch operation, limiting throughput compared to continuous casting or simple sintering methods.

Thermal Balance

There is a delicate balance required in the heating profile.

While high temperatures aid densification, excessive heat or prolonged processing times can lead to unwanted grain growth. You must precisely control the 873 K setpoint to maximize density without degrading the material's microstructural benefits.

Making the Right Choice for Your Goal

When configuring your VHP process for Mg3Sb2, consider your specific performance targets:

- If your primary focus is Electrical Conductivity: Prioritize maximizing axial pressure (up to 70 MPa) to eliminate pore scattering and achieve relative density >96%.

- If your primary focus is Compositional Purity: Ensure your system maintains a high-vacuum environment throughout the heating cycle to protect the reactive Magnesium from oxidation.

By leveraging the combined forces of heat and pressure in a controlled vacuum, you transform loose powder into a robust, high-efficiency thermoelectric component.

Summary Table:

| Parameter | Process Role | Impact on Mg3Sb2 |

|---|---|---|

| Axial Pressure | 70 MPa Mechanical Force | Triggers plastic flow to eliminate microscopic pores |

| Sintering Temp | 873 K Thermal Energy | Enables diffusion bonding and particle welding |

| Vacuum Level | Oxygen-free Environment | Prevents magnesium oxidation and ensures purity |

| Target Density | >96% Relative Density | Maximizes electrical conductivity and conversion efficiency |

Elevate Your Materials Research with KINTEK

Precision matters when synthesizing high-performance thermoelectrics like Mg3Sb2. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Hot Pressing (VHP) systems, Muffle, Tube, Rotary, and CVD furnaces tailored for your laboratory's specific temperature and pressure requirements.

Our customizable high-temperature solutions ensure your materials achieve near-theoretical density and exceptional purity through precise thermal-mechanical control. Contact us today to discuss your unique project needs and discover how our advanced furnace technology can optimize your production of high-density functional materials.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the technical advantages of a Spark Plasma Sintering (SPS) system? Achieve Superior TiB2 Ceramic Performance

- Why is a Vacuum Hot Pressing Sintering Furnace Essential for 6061-20IQC? Unlock High-Performance Composites

- What physical conditions does a vacuum hot-pressing furnace provide? Optimize GNPs-Cu/Ti6Al4V Composite Preparation

- What are the advantages of spark plasma sintering (SPS) over traditional forging? Precision Microstructural Control

- How does vacuum hot pressing improve material properties? Achieve Denser, Stronger Materials with Precision

- What are the steps in the hot press sintering process? Achieve Superior Material Density and Performance

- What is the role of the vacuum environment in SiC/ZTA sintering? Enhance Densification & Material Purity

- What are the processing advantages of RHS or SPS for A357 aluminum composites? Achieve Near-Full Density Faster