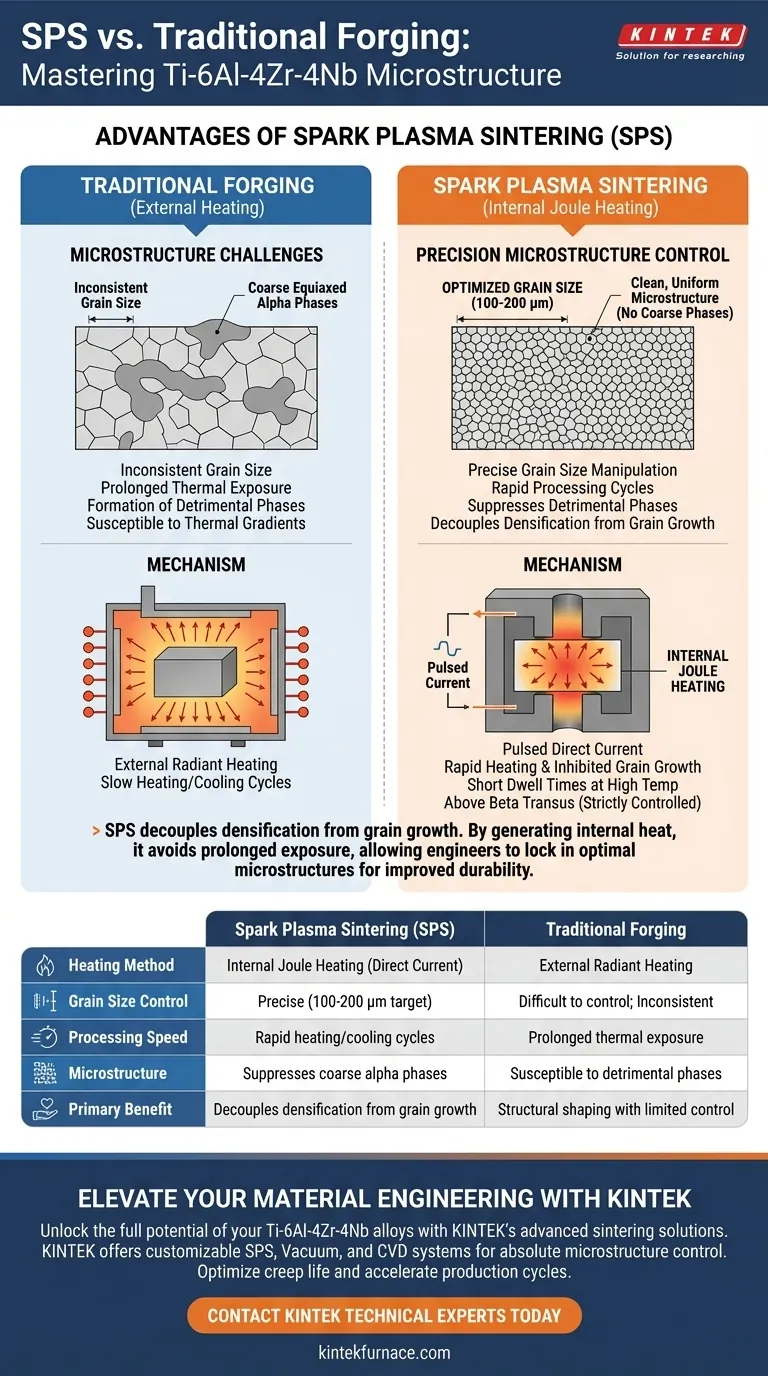

Spark plasma sintering (SPS) provides superior microstructural control compared to traditional forging, specifically by enabling precise grain size manipulation and preventing detrimental phase formation. By utilizing rapid processing cycles and sintering temperatures above the beta transus, SPS enhances the mechanical integrity and creep life of Ti-6Al-4Zr-4Nb alloys.

The core advantage of SPS lies in its ability to decouple densification from grain growth. By generating internal heat for rapid consolidation, it avoids the prolonged thermal exposure of forging, allowing engineers to lock in optimal microstructures that improve the alloy's long-term durability.

Precision Microstructure Management

Controlling Grain Size

The primary benefit of applying SPS to Ti-6Al-4Zr-4Nb is the ability to maintain grain size within a specific, optimized range of 100 to 200 μm.

This is achieved by carefully manipulating sintering temperatures, specifically pushing them above the beta transus temperature.

Unlike forging, which can result in inconsistent grain structures due to thermal gradients, SPS offers a high degree of customization to meet specific performance requirements.

Eliminating Detrimental Phases

Traditional thermal processing often leads to the formation of coarse equiaxed alpha phases.

These phases can compromise the material's mechanical properties, particularly under high-stress conditions.

SPS effectively suppresses the formation of these coarse phases, resulting in a cleaner, more uniform microstructure that directly contributes to extended creep life.

The Mechanism Behind the Advantage

Internal Joule Heating

SPS differs fundamentally from traditional methods by passing a pulsed current directly through the mold or sample.

This generates Joule heat internally, rather than relying on external radiant heating used in resistance furnaces.

This internal heating mechanism, combined with axial pressure, allows for rapid heating rates that traditional forging cannot match.

Inhibiting Grain Growth

Because the heating is internal and rapid, the material spends significantly less time at high temperatures.

This "plasma activation effect" promotes grain boundary diffusion necessary for densification while simultaneously inhibiting unwanted grain growth.

The result is a fully dense material achieved in a fraction of the time, preserving the fine microstructural features that are often lost during the long dwell times of conventional processing.

Understanding the Process Sensitivities

The Criticality of Temperature Targets

While SPS offers superior control, it requires precise adherence to specific temperature windows.

To achieve the cited benefits for this specific titanium alloy, operations must be strictly controlled above the beta transus temperature.

Failing to maintain these specific parameters prevents the optimization of the grain size to the 100-200 μm target, negating the improvements in creep life.

Making the Right Choice for Your Goal

To maximize the utility of Ti-6Al-4Zr-4Nb, select your processing method based on your specific engineering priorities:

- If your primary focus is maximizing creep life: Prioritize SPS to achieve a controlled grain size between 100 and 200 μm and eliminate coarse equiaxed alpha phases.

- If your primary focus is process efficiency: Leverage SPS for its rapid densification and shorter cycle times to reduce overall production duration.

By moving from external forging to internal spark plasma sintering, you transition from rough shaping to precise microstructural engineering.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Forging |

|---|---|---|

| Heating Method | Internal Joule Heating (Direct Current) | External Radiant Heating |

| Grain Size Control | Precise (100-200 μm target) | Difficult to control; Inconsistent |

| Processing Speed | Rapid heating/cooling cycles | Prolonged thermal exposure |

| Microstructure | Suppresses coarse alpha phases | Susceptible to detrimental phases |

| Primary Benefit | Decouples densification from grain growth | Structural shaping with limited grain control |

Elevate Your Material Engineering with KINTEK

Unlock the full potential of your Ti-6Al-4Zr-4Nb alloys with KINTEK’s advanced sintering solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers customizable Spark Plasma Sintering (SPS), Vacuum, and CVD systems designed to give you absolute control over microstructure and mechanical integrity. Whether you need to optimize creep life or accelerate production cycles, our high-temp lab furnaces are tailored to meet your unique research and industrial requirements.

Ready to transform your results? Contact our technical experts today to find the perfect system for your lab!

Visual Guide

References

- Shilong Liang, Yoko Yamabe‐Mitarai. Microstructure Evolution and Mechanical Properties of Ti–6Al–4Zr–4Nb Alloys Fabricated by Spark Plasma Sintering (SPS). DOI: 10.1007/s11661-024-07422-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the primary function of the vacuum environment in a vacuum hot press furnace during the sintering of graphite flake/copper composites? Ensure High-Performance Thermal Conductivity

- What is the primary function of graphite foil within the FAST system? Optimize Your Sintering and Tooling Protection

- What is the function of Molybdenum Disulfide (MoS2) coating on molds during vacuum hot press sintering? Protect Your Samples and Molds from Damage

- What is the core function of a vacuum hot press furnace in manufacturing high-density graphite/copper composites? The Forced-Wetting Solution for Superior Composites

- How does a vacuum press machine work in shaping metals? Achieve Precision Metal Forming with Uniform Pressure

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- How does the heating mechanism of a vacuum hot pressing sintering furnace differ from SPS? A Comparative Guide

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability