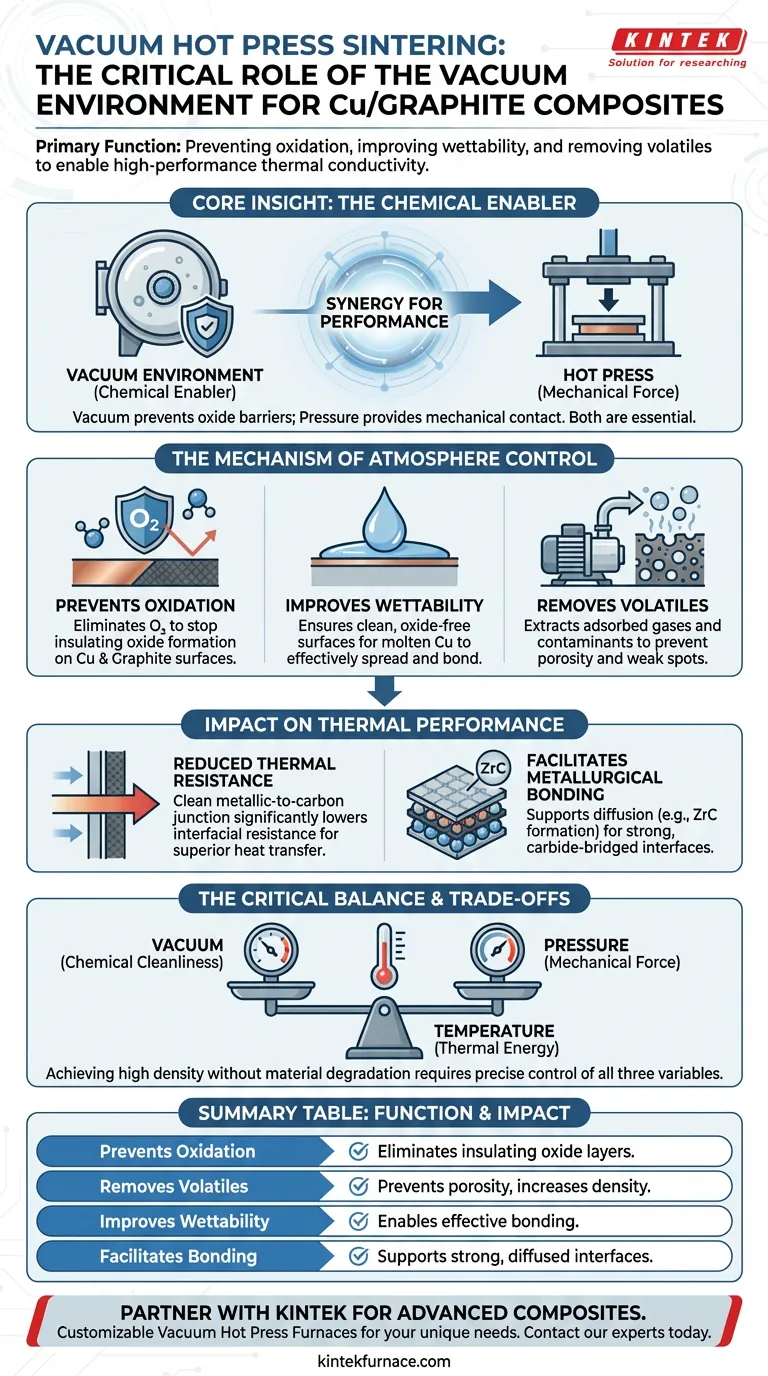

The primary function of the vacuum environment in a vacuum hot press furnace is to prevent oxidation reactions between the copper matrix and graphite reinforcement during high-temperature sintering. By creating a high-purity atmosphere, the vacuum preserves the physicochemical properties of the raw materials and removes adsorbed gases, which is essential for facilitating the wetting of the graphite surface by the copper.

Core Insight: In the context of copper/graphite composites, the vacuum environment acts as a chemical enabler while the hot press provides the mechanical force. Without the vacuum to prevent oxide barriers, even extreme mechanical pressure cannot achieve the low interfacial thermal resistance required for high-performance thermal conductivity.

The Mechanism of Atmosphere Control

Preventing Material Degradation

At the sintering temperatures required for copper (approximately 980°C to 1020°C), both copper and graphite are highly reactive to oxygen.

The vacuum environment eliminates oxygen from the chamber, preventing the copper matrix from forming insulating oxides. Simultaneously, it protects the graphite flakes from oxidation, which would degrade the reinforcement structure.

Improving Wettability

Copper and graphite naturally exhibit a "non-wetting" behavior, meaning molten or softened copper resists spreading over graphite surfaces.

Surface oxides exacerbate this issue by acting as a barrier. By maintaining a clean, oxide-free environment, the vacuum assists the copper in effectively wetting the graphite surface, which is a prerequisite for bonding.

Removal of Volatiles

Raw powder materials often contain adsorbed gases and volatiles on their surfaces.

The vacuum system actively extracts these contaminants before and during the heating phase. Removing these impurities prevents gas pockets from becoming trapped within the composite, which would otherwise form pores and weaken the material.

Impact on Thermal Performance

Reducing Interfacial Thermal Resistance

The ultimate goal of a copper/graphite composite is high thermal conductivity.

The interface between the copper and the graphite is the critical bottleneck for heat transfer. By preventing oxide formation—which acts as a thermal insulator—the vacuum ensures a clean metallic-to-carbon interface, significantly reducing thermal resistance.

Facilitating Metallurgical Bonding

In advanced sintering processes involving additives like zirconium, the vacuum plays a supporting role in chemical reactions.

It provides the stable environment needed for thermal energy to drive diffusion, such as the migration of zirconium atoms to form a Zirconium Carbide (ZrC) layer. This transforms the interface from a weak mechanical bond to a strong metallurgical bond.

Understanding the Trade-offs

Vacuum is Necessary, but Insufficient

While a vacuum ensures chemical cleanliness, it cannot overcome the physical limitations of the materials on its own.

Because copper and graphite are inherently non-wetting, a vacuum environment alone will not result in a dense composite. It must be coupled with high mechanical pressure (e.g., 40 MPa) to physically force the copper into the voids between graphite flakes.

The Balance of Temperature and Evaporation

Achieving high density requires high temperatures to soften the copper matrix or form a liquid phase.

However, operating in a high vacuum at temperatures approaching the melting point of the matrix requires careful control to avoid vaporizing volatile alloying elements. The process relies on a precise balance of vacuum level, temperature, and mechanical pressure to densify the material without altering its composition.

Optimizing Process Parameters for Your Goals

To achieve specific material properties, you must balance the vacuum environment with other sintering variables.

- If your primary focus is Thermal Conductivity: Prioritize high vacuum levels to minimize oxygen content, as even thin oxide layers at the interface will drastically impede heat flow.

- If your primary focus is Material Density: Focus on the "thermal-mechanical coupling" mentioned in your references; ensure the mechanical pressure (40 MPa) is applied while the matrix is in a softened or liquid phase to fill all micropores.

- If your primary focus is Bonding Strength: utilize the vacuum to facilitate the diffusion of active elements (like zirconium) to create carbide interlayers that bridge the copper-graphite mismatch.

The vacuum environment is not merely a protective measure; it is the fundamental baseline that allows pressure and temperature to successfully densify the composite.

Summary Table:

| Function | Impact on Composite |

|---|---|

| Prevents Oxidation | Eliminates insulating oxide layers at the copper-graphite interface. |

| Removes Volatiles | Prevents gas pockets and porosity, leading to higher material density. |

| Improves Wettability | Enables effective copper-to-graphite bonding by creating a clean surface. |

| Facilitates Metallurgical Bonding | Supports diffusion processes for stronger, carbide-bridged interfaces. |

Achieve optimal thermal performance and material density for your advanced composites. The sintering process is a delicate balance of vacuum, temperature, and pressure. Backed by expert R&D and manufacturing, KINTEK offers Vacuum Hot Press Furnaces and other lab high-temp systems, all customizable for your unique material science needs. Contact our experts today to discuss how we can help you perfect your sintering process.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering