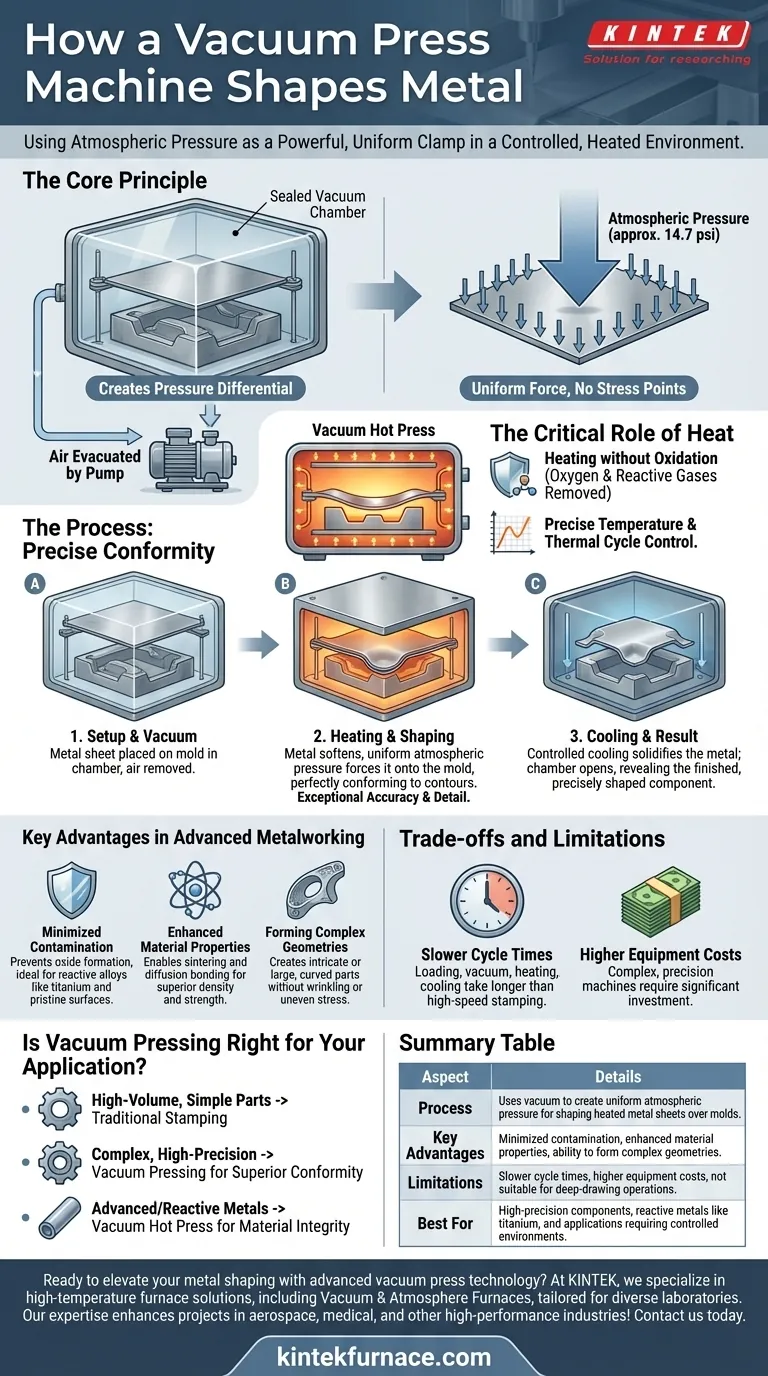

At its core, a vacuum press shapes metal by using atmospheric pressure as a powerful and perfectly uniform clamp. The process involves placing a metal sheet over a mold within a sealed chamber and then removing the air from underneath it. This creates a significant pressure differential between the chamber's interior and the outside atmosphere, forcing the heated, malleable metal sheet to conform precisely to the mold's shape.

The true value of vacuum pressing in metallurgy is not just the shaping force itself, but its ability to create a highly controlled environment. By combining vacuum with precise temperature control, the process enables the fabrication of complex parts and advanced materials with enhanced properties and minimal contamination.

The Mechanics of Vacuum Pressing: More Than Suction

The term "vacuum suction" is slightly misleading; the machine doesn't pull the metal down. Instead, it removes the air supporting the metal from below, allowing the immense weight of the atmosphere to push it down.

Creating the Pressure Differential

A powerful pump evacuates the air from the space between the metal sheet and the mold. This creates a near-vacuum on one side of the sheet.

Simultaneously, the outside of the sheet is exposed to normal atmospheric pressure, which is approximately 14.7 pounds per square inch (psi) at sea level. This seemingly small pressure, when applied over a large surface area, generates thousands of pounds of force.

This force is distributed perfectly evenly across the entire surface of the metal, eliminating the stress points that can occur with mechanical clamps or presses.

The Critical Role of Heat

Unlike plastics, metals require significant heat to become malleable enough to form. Vacuum presses used for metal are almost always vacuum hot presses.

The vacuum chamber is an ideal environment for heating. It allows the metal to be heated uniformly without the risk of oxidation, as the oxygen and other reactive gases have been removed. This is crucial for maintaining the material's structural integrity.

Achieving Precise Conformity

As the heated metal softens, the constant, uniform atmospheric pressure forces it onto the mold. It follows every detail and contour with exceptional accuracy.

Once the forming is complete, the controlled environment of the press can also manage the cooling rate. This control over the entire thermal cycle is essential for achieving desired metallurgical properties in the final product.

Key Advantages in Advanced Metalworking

The unique environment of a vacuum hot press furnace provides benefits that are critical for aerospace, medical, and other high-performance industries.

Minimized Contamination

By removing reactive gases like oxygen, the vacuum prevents the formation of oxides and other impurities on the metal's surface, especially at high temperatures. This is essential when working with reactive alloys like titanium or producing components with pristine surfaces.

Enhanced Material Properties

The process is not just for shaping. The precise control over temperature and pressure cycles allows for metallurgical processes like sintering (fusing powdered metal into a solid mass) and diffusion bonding (joining dissimilar metals at an atomic level). This results in materials with superior density, strength, and performance.

Forming Complex Geometries

The uniform pressure allows for the creation of intricate or large, gently curved parts that would be difficult or impossible to produce with traditional stamping, which can cause wrinkling or uneven stress.

Understanding the Trade-offs and Limitations

While powerful, vacuum pressing is a specialized technology with specific constraints. It is not a universal solution for all metal forming tasks.

Slower Cycle Times

The process of loading, sealing the chamber, pulling a vacuum, heating, forming, and cooling is inherently slower than high-speed mechanical stamping. This makes it less suitable for high-volume, low-cost part production.

Higher Equipment Costs

Vacuum hot press furnaces are complex, precision machines. The initial investment and ongoing operational costs are significantly higher than for most conventional presses.

Material and Shape Constraints

The process is best suited for forming metal sheets. It is not practical for deep-drawing operations, where the metal must be stretched significantly, as this can lead to tearing or excessive thinning.

Is Vacuum Pressing Right for Your Application?

Choosing the right forming method depends entirely on your project's material, complexity, and production volume goals.

- If your primary focus is high-volume production of simple parts: Traditional mechanical stamping or hydroforming will almost always be more cost-effective.

- If your primary focus is forming complex, high-precision components from standard alloys: Vacuum pressing offers superior conformity and detail compared to many other methods.

- If your primary focus is working with advanced or reactive metals (like titanium): The controlled, oxygen-free environment of a vacuum hot press is essential for maintaining material integrity and achieving desired metallurgical properties.

By understanding its principles and trade-offs, you can leverage vacuum pressing to achieve component quality and material characteristics that are impossible with conventional methods.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Uses vacuum to create uniform atmospheric pressure for shaping heated metal sheets over molds. |

| Key Advantages | Minimized contamination, enhanced material properties, ability to form complex geometries. |

| Limitations | Slower cycle times, higher equipment costs, not suitable for deep-drawing operations. |

| Best For | High-precision components, reactive metals like titanium, and applications requiring controlled environments. |

Ready to elevate your metal shaping with advanced vacuum press technology? At KINTEK, we specialize in high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for diverse laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring precise temperature control, uniform heating, and minimal contamination for superior results. Contact us today to discuss how our expertise can enhance your projects in aerospace, medical, and other high-performance industries!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure