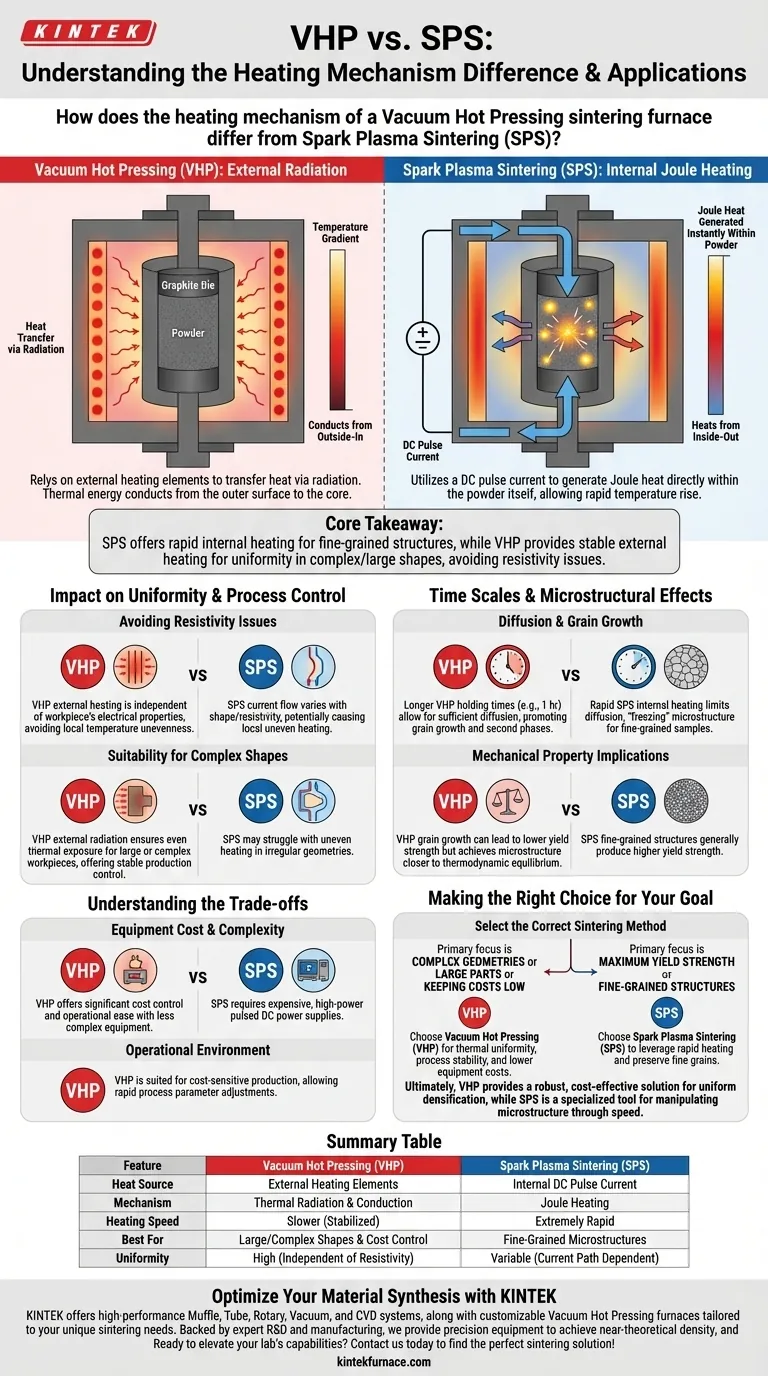

The fundamental difference lies in the origin of the thermal energy. A vacuum hot pressing (VHP) furnace relies on external heating elements to transfer heat via radiation from the outside surface into the powder. In contrast, Spark Plasma Sintering (SPS) utilizes a DC pulse current to generate Joule heat directly within the powder itself.

Core Takeaway While SPS offers rapid internal heating ideal for fine-grained structures, Vacuum Hot Pressing provides a stable, external heating environment. This makes VHP superior for controlling uniformity in complex or large shapes where electrical resistivity variations might otherwise cause uneven heating.

Distinct Mechanisms of Heat Generation

Vacuum Hot Pressing: External Radiation

In a VHP furnace, the heating elements are located outside the mold or pressing area. These elements generate heat which is transferred to the workpiece primarily through radiation.

Because the heat source is external, thermal energy must conduct from the outer surface of the material to its core. This process relies on standard thermal conduction principles to achieve temperature equilibrium throughout the powder compact.

Spark Plasma Sintering: Internal Joule Heating

SPS takes a radically different approach by passing a pulsed direct current (DC) through the graphite die and the powder compact.

This current encounters resistance within the material, generating Joule heat instantly throughout the volume of the powder. Instead of waiting for heat to travel from the outside in, the material heats up from the inside out, allowing for extremely rapid temperature distinct rise rates.

Impact on Uniformity and Process Control

Avoiding Resistivity Issues

A major advantage of the VHP external heating method is its independence from the electrical properties of the workpiece.

In SPS, differences in the workpiece's shape or electrical resistivity can alter how current flows, potentially leading to local temperature unevenness. VHP avoids this completely because the heat is applied environmentally rather than electrically.

Suitability for Complex Shapes

Because VHP does not rely on current paths, it is often more effective for large or complex workpieces.

The external radiation ensures that even irregular geometries receive consistent thermal exposure, making the process easier to control and significantly more stable for production-scale components.

Time Scales and Microstructural Effects

Diffusion and Grain Growth

The heating mechanism dictates the processing time. VHP typically requires longer holding times (e.g., 1 hour) compared to the rapid firing of SPS (approx. 10 minutes).

This prolonged exposure to heat in VHP allows for more sufficient diffusion of alloy elements. This promotes grain growth and the precipitation of second phases, such as the sigma phase, which results in distinct phase compositions.

Mechanical Property Implications

The rapid internal heating of SPS limits diffusion, effectively "freezing" the microstructure. This generally produces fine-grained samples with higher yield strength.

Conversely, the grain growth associated with the slower VHP process may result in lower yield strength, but it achieves a microstructure that is closer to thermodynamic equilibrium.

Understanding the Trade-offs

Equipment Cost and Complexity

While both methods achieve high densification, VHP offers significant advantages in cost control and operational ease.

The equipment required for external radiative heating is generally less complex and less expensive than the high-power pulsed DC power supplies required for SPS.

Operational Environment

VHP is often better suited for cost-sensitive production environments. It allows for the rapid adjustment of process parameters without the volatility associated with managing high-current pulses through changing powder resistances.

Making the Right Choice for Your Goal

To select the correct sintering method, you must weigh the importance of microstructural refinement against process stability and cost.

- If your primary focus is complex geometries or large parts: Choose Vacuum Hot Pressing (VHP) to ensure thermal uniformity and avoid issues caused by varying electrical resistivity.

- If your primary focus is keeping costs low: Choose VHP for its lower equipment costs and operational simplicity while still achieving near-theoretical density.

- If your primary focus is maximum yield strength: Choose Spark Plasma Sintering (SPS) to leverage rapid heating that preserves fine grain structures.

Ultimately, VHP provides a robust, cost-effective solution for uniform densification, while SPS is a specialized tool for manipulating microstructure through speed.

Summary Table:

| Feature | Vacuum Hot Pressing (VHP) | Spark Plasma Sintering (SPS) |

|---|---|---|

| Heat Source | External Heating Elements | Internal DC Pulse Current |

| Mechanism | Thermal Radiation & Conduction | Joule Heating |

| Heating Speed | Slower (Stabilized) | Extremely Rapid |

| Best For | Large/Complex Shapes & Cost Control | Fine-Grained Microstructures |

| Uniformity | High (Independent of Resistivity) | Variable (Current Path Dependent) |

Optimize Your Material Synthesis with KINTEK

Choosing between VHP and SPS is critical for your project's success. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable Vacuum Hot Pressing furnaces tailored to your unique sintering needs. Whether you require the thermal stability of VHP for complex geometries or specialized lab high-temp furnaces, our team provides the precision equipment necessary to achieve near-theoretical density and desired microstructures.

Ready to elevate your lab's capabilities? Contact us today to find the perfect sintering solution!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What types of heating elements are used in vacuum hot press furnaces? Optimize for High-Temp Performance

- What is the primary purpose of using a high-precision laboratory uniaxial hydraulic press to compact powders?

- What role do vacuum presses play in plastic forming and lamination? Essential Guide for Precision Fabrication

- What is the function of graphite dies in vacuum hot pressing? Optimize Austenitic Stainless Steel Sintering Results

- What is the vacuum hot pressing technique? Achieve Maximum Density & Purity for Advanced Materials

- What Role Does a Graphite Mold Play in Vacuum Hot Pressing? Enhancing Composite Sintering Efficiency

- What safety features are incorporated in vacuum hot press furnaces? Ensure Operator and Equipment Protection

- What advantages does a vacuum hot press furnace demonstrate for Fe-Cu-Ni-Sn-VN composites? Superior Nanostructure Prep