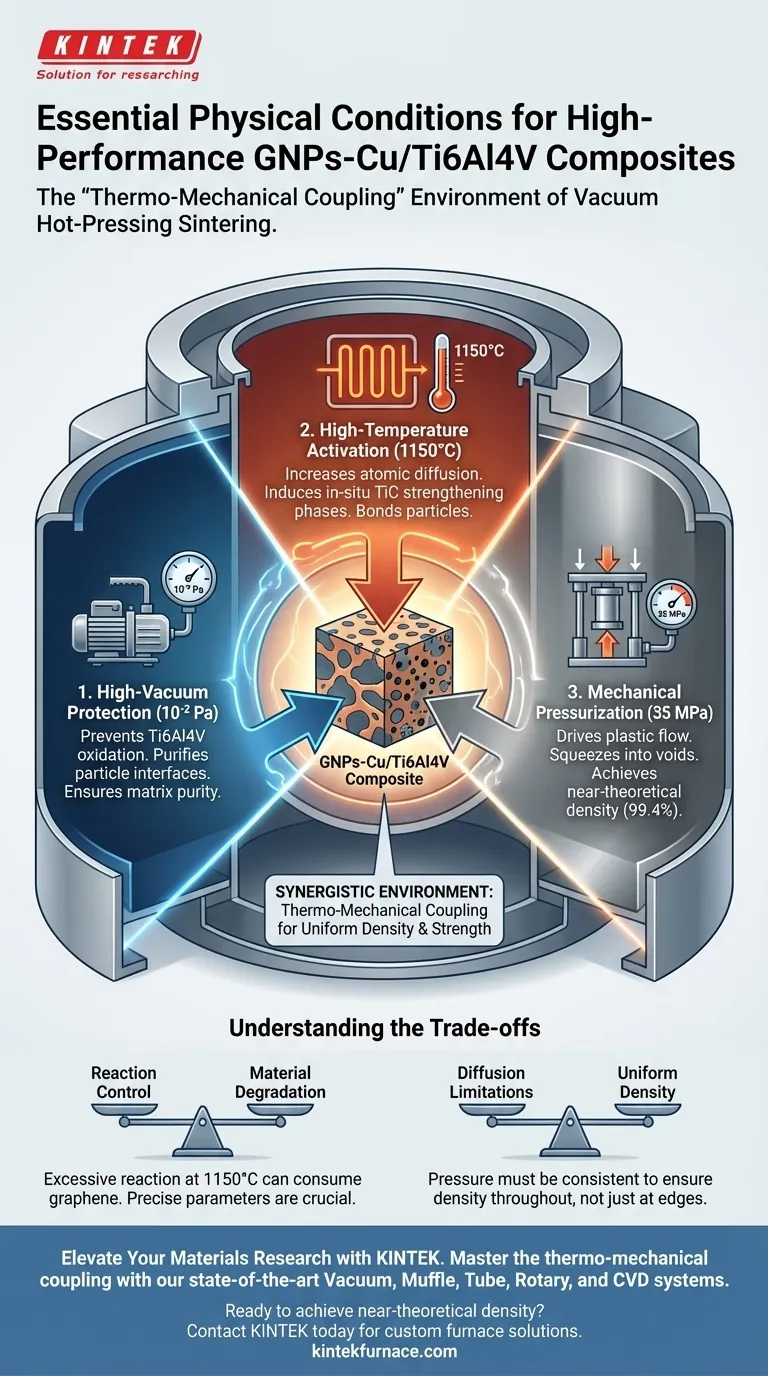

The vacuum hot-pressing sintering furnace creates a critical "thermo-mechanical coupling" environment characterized by three specific physical conditions: a high vacuum ($10^{-2}$ Pa), high temperature (1150°C), and substantial mechanical pressure (35 MPa). These conditions are essential for processing GNPs-Cu/Ti6Al4V composites to prevent the rapid oxidation of the titanium alloy matrix while forcing the material to achieve near-theoretical density through plastic flow.

Core Takeaway The fundamental challenge in fabricating titanium-based composites is balancing densification with chemical purity. The vacuum hot-pressing furnace solves this by utilizing mechanical pressure to physically close pores and vacuum to prevent oxidation, allowing thermal energy to bond particles and generate strengthening phases without degrading the matrix.

The Synergistic Physical Environment

To prepare high-performance composites, specifically those with a Titanium alloy (Ti6Al4V) matrix reinforced by Graphene Nanoplatelets (GNPs) and Copper (Cu), the equipment must maintain a delicate balance of three forces.

1. High-Vacuum Protection ($10^{-2}$ Pa)

The most immediate threat to titanium alloys at elevated temperatures is oxidation. Titanium is highly reactive; even trace amounts of oxygen can form brittle oxide layers that ruin the material's mechanical properties.

Preventing Matrix Oxidation The furnace establishes a vacuum environment of $10^{-2}$ Pa. This effectively eliminates oxygen from the chamber, ensuring the Ti6Al4V matrix retains its purity and metallic characteristics during the heating cycle.

Interface Purification Beyond preventing oxidation, the vacuum aids in evacuating adsorbed gases and volatile impurities trapped within the powder interstices. This purification is vital for ensuring high wettability and atomic-level contact between the matrix and the reinforcement phases.

2. Thermo-Mechanical Coupling

The unique advantage of this equipment is the simultaneous application of heat and pressure, often referred to as a "thermo-mechanical coupling field."

High-Temperature Activation (1150°C) The furnace heats the composite to 1150°C. At this temperature, the atomic diffusion rates increase significantly, allowing the powder particles to bond. Crucially, this thermal energy induces the in-situ generation of strengthening phases, specifically Titanium Carbide (TiC). This occurs as the titanium reacts continuously with available carbon sources (such as the GNPs), creating a harder, stiffer composite.

Mechanical Pressurization (35 MPa) While heat softens the material, pressure is required to densify it. The furnace applies 35 MPa of mechanical pressure. This force drives the plastic flow of the powder particles, physically squeezing them into voids and gaps. This mechanism is responsible for achieving relative densities as high as 99.4%, effectively eliminating porosity that would otherwise weaken the final part.

Understanding the Trade-offs

While vacuum hot pressing is effective, the process involves inherent compromises that must be managed to ensure composite quality.

Reaction Control vs. Material Degradation

The high temperature (1150°C) promotes the formation of TiC, which strengthens the material. However, this is a double-edged sword. Excessive reaction between the Titanium matrix and the Graphene Nanoplatelets (GNPs) can consume the graphene, destroying the very reinforcement you are trying to introduce. The process parameters must be precise to allow bonding without depleting the reinforcement.

Diffusion Limitations

Unlike liquid-phase casting, this is primarily a solid-state or semi-solid process. The densification relies heavily on atomic diffusion and plastic deformation. If the pressure is applied unevenly or if the "hold time" is insufficient, the center of the composite may remain porous while the edges are dense. The mechanical pressure (35 MPa) must be maintained consistently to ensure uniform density throughout the part.

Making the Right Choice for Your Goal

When configuring a vacuum hot-pressing cycle for GNPs-Cu/Ti6Al4V, prioritize your parameters based on the specific performance metric you need to maximize.

- If your primary focus is Maximum Density (Porosity Elimination): Prioritize maintaining the 35 MPa mechanical pressure throughout the high-temperature dwell time to force plastic flow into every void.

- If your primary focus is Interfacial Strength: Ensure the vacuum level is strictly maintained at $10^{-2}$ Pa or better to strip all oxides, allowing for pristine atomic diffusion between the Cu/GNPs and the Ti matrix.

- If your primary focus is Hardness/Reinforcement: Carefully control the 1150°C temperature profile; higher or longer heat exposure will increase TiC formation, increasing hardness but potentially reducing ductility.

Success in fabricating these composites relies on the precise synchronization of vacuum purity, thermal energy, and mechanical force to drive diffusion while protecting the reactive matrix.

Summary Table:

| Physical Parameter | Required Value | Critical Role in Composite Fabrication |

|---|---|---|

| Vacuum Level | $10^{-2}$ Pa | Prevents Ti6Al4V oxidation and purifies particle interfaces. |

| Temperature | 1150°C | Increases atomic diffusion and induces in-situ TiC strengthening phases. |

| Mechanical Pressure | 35 MPa | Drives plastic flow to achieve near-theoretical density (99.4%). |

| System State | Thermo-Mechanical | Synchronizes heat and force to eliminate porosity without degradation. |

Elevate Your Materials Research with KINTEK

Precision is non-negotiable when dealing with reactive matrices like Titanium and advanced reinforcements like Graphene. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Vacuum, Muffle, Tube, Rotary, and CVD systems designed to master the thermo-mechanical coupling your composites require.

Whether you need a specialized vacuum hot-pressing furnace or a customizable high-temp system for unique laboratory needs, our equipment ensures consistent density, purity, and performance.

Ready to achieve near-theoretical density in your next project? Contact KINTEK today to discuss your custom furnace solution.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the advantages of using WC-Co anvils in UHP-SPS? Unlock Extreme Sintering Pressures and Material Density

- How do the temperature and pressure conditions in a vacuum hot-pressing furnace facilitate the densification of AMC?

- How does a vacuum press machine work in shaping metals? Achieve Precision Metal Forming with Uniform Pressure

- How does a Vacuum Hot Pressing (VHP) furnace prepare high-performance P-type Mg3Sb2 thermoelectric materials?

- What are the common applications of vacuum hot pressing? Essential for High-Performance Materials

- What industrial applications utilize vacuum hot press furnaces? Essential for Aerospace, Medical, and Electronics

- What are the technical advantages of rapid hot pressing for Sn-Ag-Bi-Se-Te/MWCNTs? Achieve 98%+ Density in 15 Minutes

- What are the main components of a vacuum hot press sintering furnace? Unlock Precision in Material Densification