At its core, a vacuum hot press furnace is used in industries where material performance is non-negotiable. Its primary applications are in aerospace for creating lightweight superalloys, medical for producing biocompatible implants, electronics for fabricating high-purity semiconductors, and in advanced materials manufacturing for sintering ceramics and consolidating metal powders into components with superior strength and density.

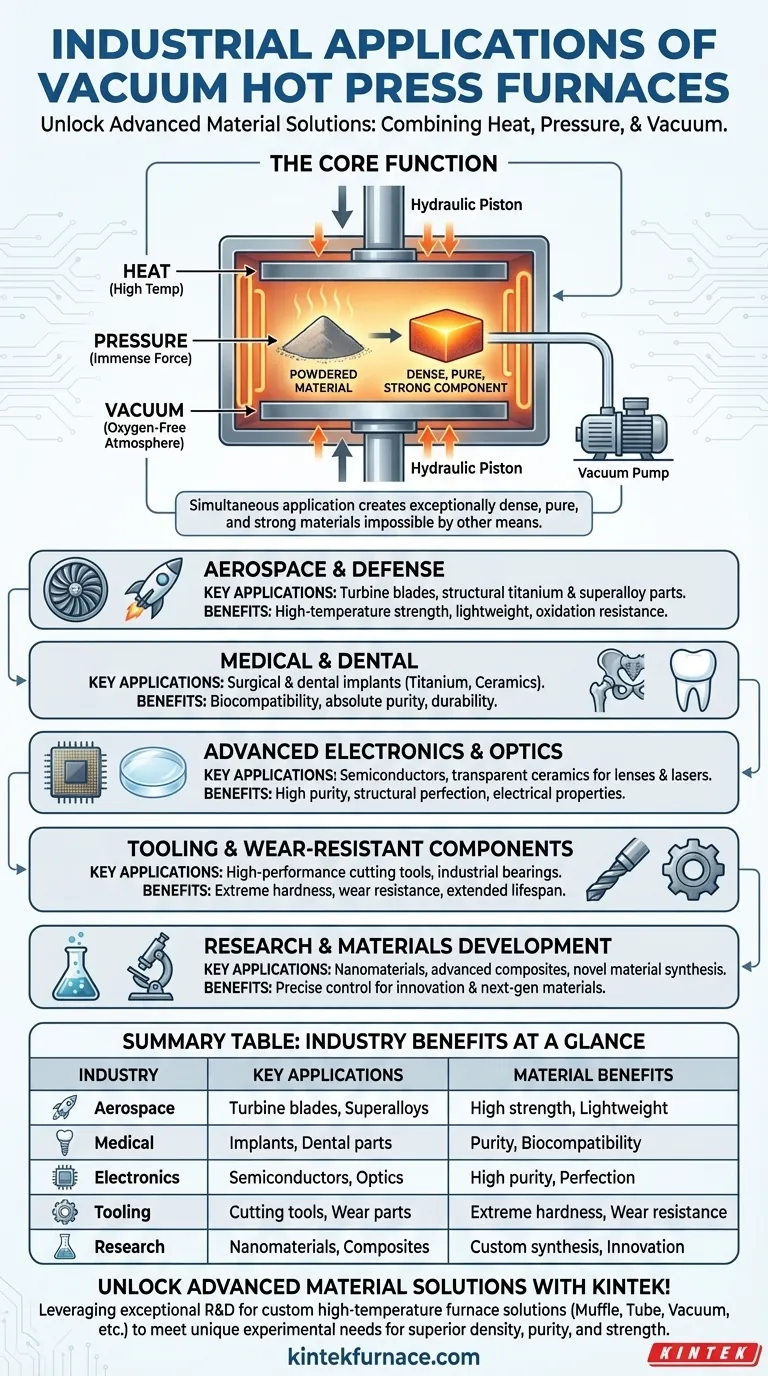

The true value of a vacuum hot press is not simply heating a material. It is the simultaneous application of high temperature and immense pressure within a controlled, oxygen-free atmosphere to create exceptionally dense, pure, and strong materials that are often impossible to produce by other means.

The Core Function: Combining Heat, Pressure, and Vacuum

Understanding the industrial applications begins with understanding the three fundamental problems this technology solves. A vacuum hot press uniquely combines these elements to achieve specific material outcomes.

Achieving Maximum Density

The process, often called sintering or consolidation, applies mechanical pressure to a material—typically a powder—as it is heated.

This force physically compacts the material, squeezing out the voids and porosity between particles. The result is a solid, fully dense component, which is critical for high-performance ceramics and powder metallurgy.

Preventing Oxidation and Contamination

Heating reactive metals like titanium or superalloys in the open air would cause them to oxidize and become brittle, destroying their valuable properties.

The vacuum or inert gas atmosphere inside the furnace removes oxygen and other contaminants. This ensures the material remains pure and retains its intended chemical composition, which is vital for aerospace components, medical implants, and semiconductors.

Creating Superior Material Properties

The combination of heat and pressure does more than just consolidate a material; it fundamentally enhances its physical characteristics.

This process improves strength, hardness, and wear resistance. This is why it's the preferred method for producing ultra-hard cutting tools and durable wear-resistant components from materials like silicon nitride and boron carbide.

A Breakdown of Key Industrial Applications

The unique capabilities of vacuum hot pressing make it indispensable in sectors that push the boundaries of material science.

Aerospace and Defense

This sector requires components that are both incredibly strong and lightweight, with the ability to withstand extreme temperatures.

Vacuum hot pressing is used to fabricate turbine blades, structural titanium alloy parts, and other superalloy components. The process guarantees the high-temperature strength and material purity necessary for engine performance and structural integrity.

Medical and Dental

Biocompatibility is the top priority for any material placed inside the human body. The slightest impurity can lead to rejection or failure.

These furnaces produce surgical and dental implants from materials like titanium and advanced ceramics. The vacuum environment ensures absolute purity, while the pressing action creates the high-strength, durable part needed to function for decades.

Advanced Electronics and Optics

The performance of a semiconductor wafer or an advanced optical lens depends on its structural perfection and chemical purity.

Vacuum hot pressing is used to sinter transparent ceramics for lenses and lasers and to fabricate specific semiconductor components. The process removes micro-porosity that would scatter light and eliminates impurities that would disrupt electrical properties.

Tooling and Wear-Resistant Components

In heavy industry and manufacturing, the hardness of a tool dictates its lifespan and effectiveness.

This technology is central to producing high-performance cutting tools, industrial bearings, and wear-resistant parts. It transforms powders like boron carbide or silicon nitride into fully dense solids with extreme hardness.

Research and Materials Development

For scientists and engineers, the vacuum hot press is a critical tool for innovation.

It is widely used in laboratories to synthesize and test novel materials, including nanomaterials, advanced composites, and metal-ceramic mixtures. The precise control over temperature, pressure, and atmosphere allows for the creation of next-generation materials.

Understanding the Trade-offs

While powerful, vacuum hot pressing is not a universal solution. It is a highly specialized process with specific constraints.

Process Complexity and Cost

Vacuum hot press furnaces are sophisticated and expensive pieces of equipment. The process requires careful control and monitoring, making it more costly than conventional furnaces or standard heat treatment.

Slower Cycle Times

Achieving a deep vacuum, ramping up to temperature, applying pressure, and cooling down is a time-consuming cycle. This makes the process less suitable for high-volume, low-cost commodity parts and better suited for high-value, performance-critical components.

Geometric Limitations

The need to apply uniform pressure via a die or press inherently limits the complexity of shapes that can be easily manufactured. While advanced techniques exist, it is best suited for parts with relatively simple geometries.

Making the Right Choice for Your Goal

Selecting the right manufacturing process depends entirely on your final objective.

- If your primary focus is maximum material purity and strength: Vacuum hot pressing is essential for reactive metals, superalloys, and high-performance ceramics where oxidation is unacceptable.

- If your primary focus is densifying powdered materials: This process is the definitive method for turning powders like ceramics or metal composites into solid, void-free components with superior physical properties.

- If your primary focus is high-volume, low-cost production: You will likely need to explore alternative, faster methods like conventional sintering or metal injection molding, as vacuum hot pressing is a specialized, high-value process.

Ultimately, vacuum hot pressing is the enabling technology for materials that define the cutting edge of modern industry.

Summary Table:

| Industry | Key Applications | Material Benefits |

|---|---|---|

| Aerospace | Turbine blades, superalloy components | High strength, lightweight, oxidation resistance |

| Medical | Biocompatible implants, dental parts | Purity, durability, biocompatibility |

| Electronics | Semiconductors, optical ceramics | High purity, structural perfection |

| Tooling | Cutting tools, wear-resistant parts | Extreme hardness, wear resistance |

| Research | Nanomaterials, advanced composites | Custom synthesis, enhanced properties |

Unlock advanced material solutions with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior density, purity, and strength in materials. Contact us today to elevate your industrial applications!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?