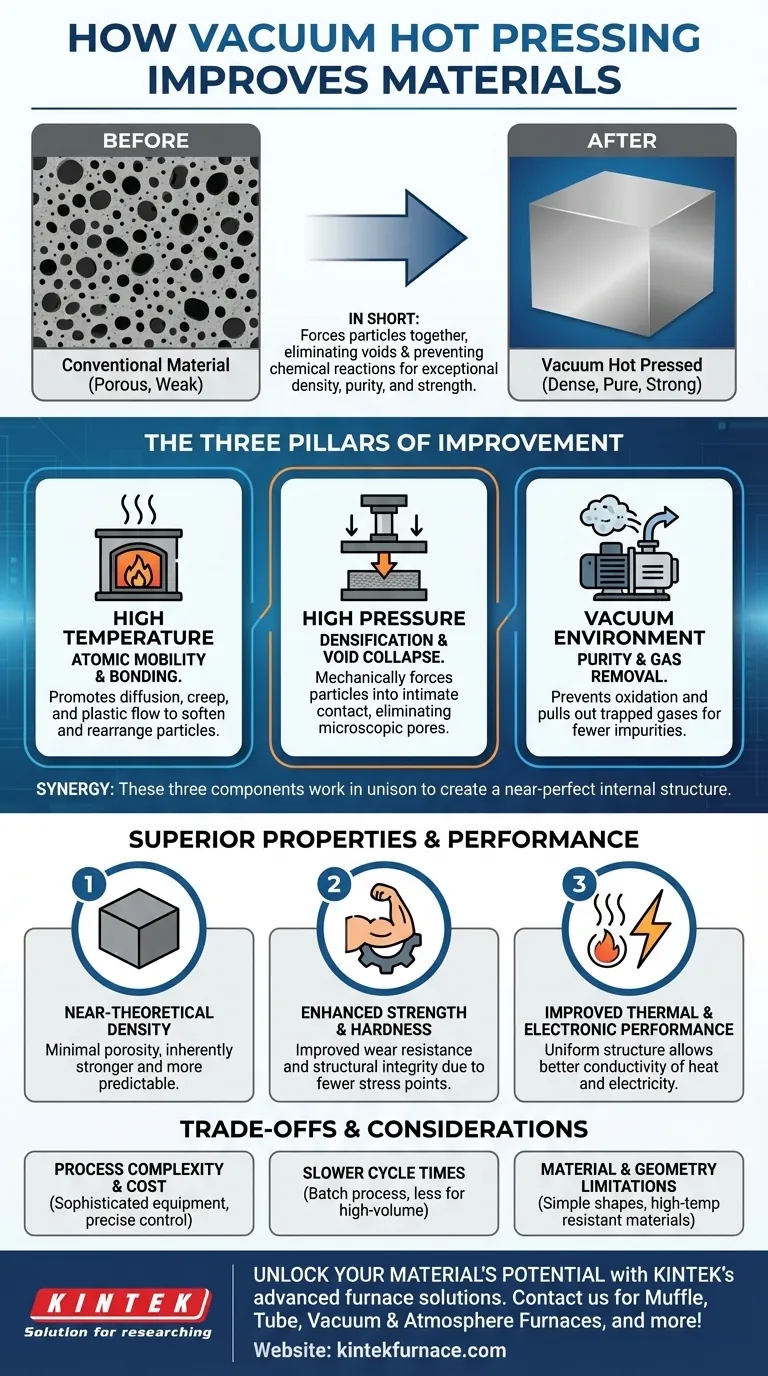

In short, vacuum hot pressing improves materials by simultaneously applying high temperature, high pressure, and a vacuum environment. This unique combination forces material particles together, eliminating internal voids and preventing chemical reactions like oxidation, which results in a final product that is exceptionally dense, pure, and strong.

The core advantage of vacuum hot pressing is its ability to create a near-perfect internal structure. By removing air and other gases while compacting the material under heat, the process systematically eliminates the microscopic defects—porosity and impurities—that weaken conventional materials.

The Three Pillars of Improvement

The enhanced properties are not the result of a single factor, but the synergy of three distinct process components working in unison: high temperature, mechanical pressure, and a vacuum environment.

The Role of High Temperature

Heat acts as the catalyst for atomic movement. It promotes mechanisms like diffusion, creep, and plastic flow, which allow the individual grains or particles of the material to soften, rearrange, and bond more effectively.

This increased atomic mobility is what enables the material to consolidate into a dense, coherent mass, effectively "healing" the gaps between particles.

The Role of High Pressure

Pressure is the driving force for densification. It mechanically forces particles into intimate contact, collapsing the microscopic voids and pores that would otherwise become trapped within the material.

This action directly increases the material's final density. By working in tandem with high temperature, pressure ensures that the rearranged particles are packed into the tightest possible configuration.

The Critical Function of the Vacuum

The vacuum environment is what elevates this process beyond standard hot pressing. Its primary function is to prevent contamination. By removing air and other reactive gases, it completely prevents oxidation and other unwanted chemical reactions on the particle surfaces.

Furthermore, the vacuum helps pull out any gases trapped within the material's pores or dissolved in the material itself. This results in a final product with significantly fewer impurities and higher structural integrity.

How This Translates to Superior Properties

The combination of densification and purification has a direct and measurable impact on the material's performance characteristics.

Achieving Near-Theoretical Density

The most significant outcome is the reduction of porosity. A dense, void-free structure is inherently stronger and performs more predictably under stress. This high density is the foundation for improvements in almost every other property.

Enhancing Mechanical Strength and Hardness

With fewer internal voids to act as stress concentration points, the material's hardness, wear resistance, and overall strength are dramatically improved. The refined, uniform microstructure ensures that loads are distributed evenly, preventing premature failure.

Improving Thermal and Electronic Performance

Voids and impurities disrupt the flow of heat and electricity. By creating a dense, pure, and uniform structure with fewer grain boundaries, vacuum hot pressing produces materials with superior thermal and electrical conductivity.

Understanding the Trade-offs

While powerful, vacuum hot pressing is not a universal solution. It involves clear trade-offs that make it suitable for specific, high-value applications.

Process Complexity and Cost

Vacuum hot press furnaces are sophisticated and expensive pieces of equipment. The process requires precise control over temperature, pressure, and vacuum levels, making it a costly and technically demanding manufacturing route.

Slower Cycle Times

Compared to methods like conventional sintering or casting, vacuum hot pressing is a batch process with longer cycle times. This makes it less suitable for high-volume, low-cost manufacturing.

Material and Geometry Limitations

The process is best suited for simple shapes like discs, blocks, or cylinders, as complex geometries can be difficult to press uniformly. Additionally, the material must be able to withstand the high temperatures and pressures without degrading.

Making the Right Choice for Your Goal

Selecting this process depends entirely on your end goal and performance requirements.

- If your primary focus is maximum performance and reliability: Vacuum hot pressing is the definitive choice for creating materials with the highest possible density, purity, and strength for mission-critical applications.

- If your primary focus is producing advanced ceramics or composites: This method is uniquely capable of consolidating materials that cannot be processed effectively by other means, such as non-oxide ceramics or dissimilar material laminates.

- If your primary focus is cost-effective mass production: You should explore alternative methods like conventional sintering or powder metallurgy, as the cost and cycle time of vacuum hot pressing may be prohibitive.

Ultimately, vacuum hot pressing is a precision tool used to engineer materials that push the boundaries of performance.

Summary Table:

| Key Aspect | Improvement |

|---|---|

| Density | Near-theoretical density with minimal porosity |

| Mechanical Strength | Enhanced hardness, wear resistance, and structural integrity |

| Purity | Reduced impurities and prevention of oxidation |

| Thermal/Electrical Conductivity | Improved due to uniform, void-free structure |

| Process Synergy | Combines high temperature, pressure, and vacuum for optimal results |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our vacuum hot pressing technologies can deliver denser, purer, and stronger materials for your critical applications!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What is the process of hot pressing? A Guide to Achieving Superior Material Density