Resistance Heating Sintering (RHS) and Spark Plasma Sintering (SPS) offer a superior processing advantage through the use of field-assisted sintering technology. By passing pulsed electric current directly through the mold or powder to generate internal Joule heat, combined with axial pressure, these methods achieve rapid heating and densification that conventional furnaces cannot match.

The definitive advantage of RHS and SPS is the ability to achieve near-full densification in a matter of minutes. This rapid thermal cycle effectively suppresses grain coarsening, preserving the fine-grain structure that is critical for the mechanical strength of aluminum matrix composites.

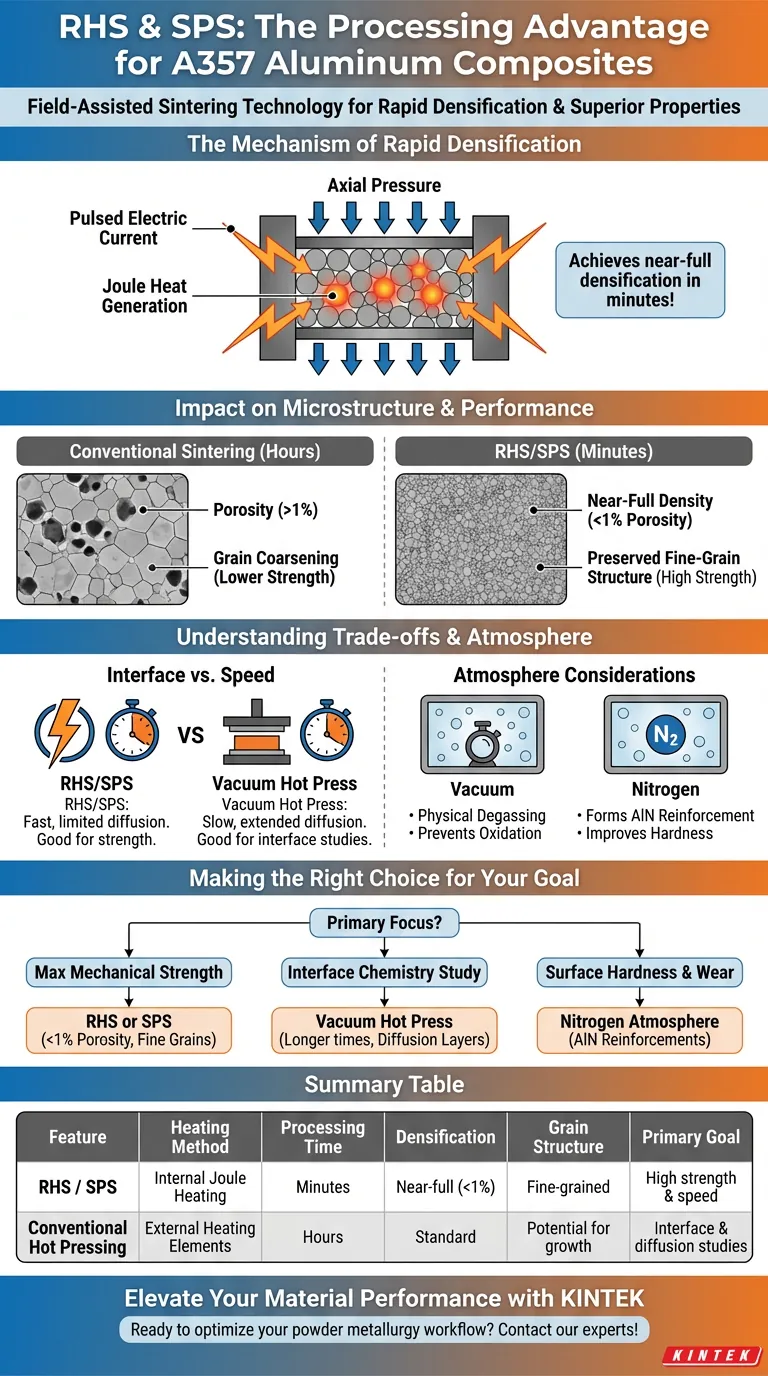

The Mechanism of Rapid Densification

Internal Joule Heating

Unlike traditional furnaces that rely on external heating elements, RHS and SPS generate heat internally. The pulsed electric current passes directly through the conductive powder or die. This creates Joule heat at the particle contact points, leading to immediate and uniform thermal distribution.

Simultaneous Pressure Application

These furnaces utilize axial pressure concurrently with the electric current. This mechanical force assists in breaking down surface oxides and rearranging particles. The combination of heat and pressure accelerates the consolidation process significantly.

Speed and Efficiency

The primary processing benefit is the extremely short sintering time. The entire process requires only a few minutes to complete. This is a drastic reduction compared to the hours often required by vacuum hot press or conventional sintering methods.

Impact on Microstructure and Performance

Achieving Near-Full Density

For A357 aluminum composites, porosity is a major defect that compromises performance. RHS and SPS can achieve a porosity of less than 1% (near-full densification). This is possible even at temperatures close to the solidus line, ensuring a solid, void-free matrix.

Preservation of Fine-Grain Strengthening

The speed of the process is not just about efficiency; it is a metallurgical necessity. Prolonged exposure to high temperatures causes metal grains to grow (coarsen), which reduces strength. Because RHS/SPS is so fast, it maximizes the suppression of grain coarsening. This preserves the fine-grain strengthening effect inherent to powder metallurgy.

Understanding the Trade-offs

Interface Evolution vs. Processing Speed

While the speed of SPS is excellent for strength, it limits atomic diffusion time. In contrast, vacuum hot press sintering maintains temperature and pressure for longer durations. This extended time allows for the formation of thicker, more distinct diffusion transition layers, which can be advantageous if your goal is to study interface evolution or thermal diffusion mechanisms.

Atmosphere Considerations

The environment inside the furnace is as critical as the heating method.

- Vacuum: Effective for physical degassing and removing volatiles, preventing oxidation of the aluminum matrix.

- Nitrogen: If a nitrogen atmosphere is used, gas can penetrate open pores. This triggers an exothermic reaction with aluminum to form aluminum nitride (AlN), a reinforcement phase that improves hardness and wear resistance.

Making the Right Choice for Your Goal

To select the optimal sintering strategy for your A357 composites, consider your specific performance requirements:

- If your primary focus is maximum mechanical strength: Prioritize RHS or SPS to minimize grain growth and achieve <1% porosity through rapid densification.

- If your primary focus is studying interface chemistry: Consider vacuum hot press sintering, as the longer holding times allow for clearer observation of diffusion transition layers.

- If your primary focus is surface hardness and wear resistance: Utilize a nitrogen atmosphere during sintering to generate dispersed aluminum nitride (AlN) reinforcements.

By leveraging the rapid internal heating of field-assisted sintering, you secure a dense, fine-grained microstructure that fully capitalizes on the potential of powder metallurgy.

Summary Table:

| Feature | Resistance Heating / SPS | Conventional Hot Pressing |

|---|---|---|

| Heating Method | Internal Joule Heating (Pulsed Current) | External Heating Elements |

| Processing Time | Minutes | Hours |

| Densification | Near-full (<1% porosity) | Standard densification |

| Grain Structure | Fine-grained (suppressed coarsening) | Potential for grain growth |

| Primary Goal | High mechanical strength & speed | Interface & diffusion studies |

Elevate Your Material Performance with KINTEK

Unlock the full potential of your A357 aluminum matrix composites with our cutting-edge sintering solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized field-assisted sintering technologies.

Whether you need to minimize grain growth through rapid densification or require a custom atmosphere for AlN reinforcement, our high-temp lab furnaces are fully customizable to meet your unique research and production needs.

Ready to optimize your powder metallurgy workflow?

Contact our technical experts today to find your perfect sintering solution.

Visual Guide

References

- Sarah Johanna Hirsch, Thomas Lampke. Combined Effect of Particle Reinforcement and T6 Heat Treatment on the Compressive Deformation Behavior of an A357 Aluminum Alloy at Room Temperature and at 350 °C. DOI: 10.3390/cryst14040317

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the function of a vacuum hot pressing furnace? Precision Diffusion Bonding for 321H Stainless Steel

- What is the purpose of using a laboratory hydraulic press for Bismuth Telluride? Optimize Thermoelectric Green Bodies

- Which industries commonly use hot press furnaces? Unlock Superior Material Performance

- What industries benefit from the use of vacuum hot press furnaces? Unlock High-Performance Materials for Your Industry

- What role does 30 MPa pressure play in SiC/Cu-Al2O3 sintering? Achieve 97.6% Density with Vacuum Hot Pressing

- What role do high-strength graphite molds play during SPS? Boost Mo-Cr-Y Composite Densification

- What are the advantages of spark plasma sintering (SPS) over traditional forging? Precision Microstructural Control

- What Role Does a Graphite Mold Play in Vacuum Hot Pressing? Enhancing Composite Sintering Efficiency