In short, vacuum hot press furnaces are essential for industries that demand materials with exceptional performance, including aerospace, medical, automotive, and electronics. They are used to create high-strength, high-purity components by simultaneously applying intense heat and pressure within a controlled, oxygen-free environment.

The true value of a vacuum hot press is not just heating, but fundamentally transforming materials. By eliminating atmospheric contamination and applying immense pressure, this technology enables the creation of advanced ceramics, composites, and alloys with properties unattainable through conventional methods.

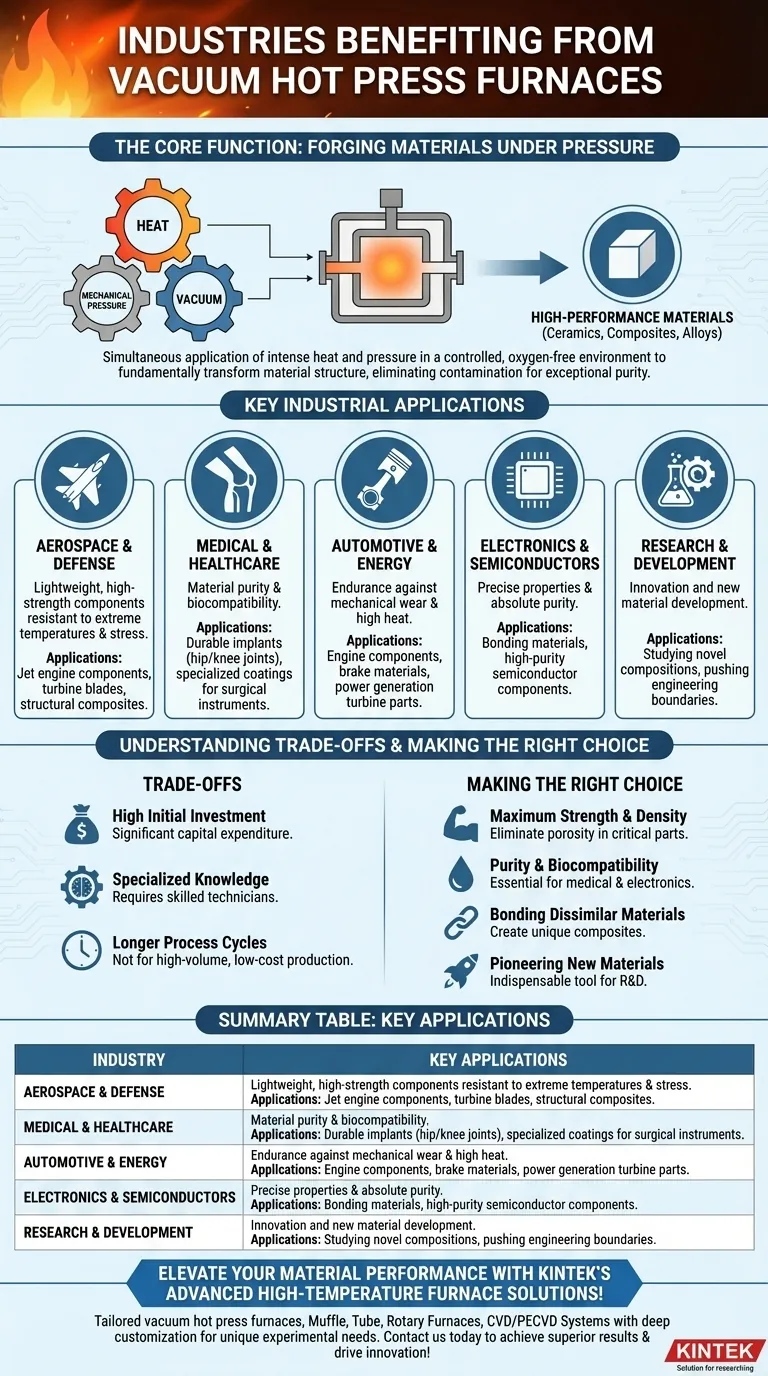

The Core Function: Forging Materials Under Pressure

A vacuum hot press furnace isn't simply an oven. It's a sophisticated system that combines three critical elements—heat, mechanical pressure, and a vacuum—to fundamentally alter a material's structure.

Why the Vacuum is Critical

The vacuum environment is the defining feature. By removing air and other gases, it prevents oxidation and other chemical reactions that would otherwise compromise the material's integrity at high temperatures.

This ensures the final product is exceptionally pure and free from contamination, which is non-negotiable for high-performance applications.

The Power of Sintering and Bonding

The primary process is hot pressing, which includes sintering and diffusion bonding. Sintering compacts and forms a solid mass of material from powder using heat and pressure, dramatically increasing its density and strength.

Diffusion bonding uses the same forces to join dissimilar materials together without any adhesives, creating unique composite parts with combined properties. This technology is capable of processing advanced ceramics, carbon composites, and metal powders.

Key Industrial Applications

The ability to create superior materials makes this technology indispensable across several key sectors. Each industry leverages the furnace's unique capabilities to solve specific, high-stakes challenges.

Aerospace & Defense

This sector requires materials that are both lightweight and incredibly resistant to extreme temperatures and stresses.

Vacuum hot presses are used to fabricate jet engine components, turbine blades, and high-strength structural composites that can withstand the harsh conditions of flight and re-entry.

Medical & Healthcare

In the medical field, material purity and biocompatibility are paramount. The technology is used to create durable, long-lasting medical implants like hip and knee joints.

It is also used to apply specialized, biocompatible, or antibacterial coatings to the surfaces of surgical instruments and other medical devices.

Automotive & Energy

High-performance automotive parts and energy generation equipment rely on materials that can endure constant mechanical wear and high heat.

Vacuum hot pressing produces durable engine components, high-performance brake materials, and parts for power generation turbines, improving both efficiency and reliability.

Electronics & Semiconductors

The electronics industry depends on materials with precise, predictable properties and absolute purity.

These furnaces are used to bond materials and create high-purity components for semiconductors and other advanced electronic systems where even microscopic contamination can cause failure.

Research & Development

For materials scientists, the vacuum hot press is a critical tool for innovation.

Laboratories and universities use these systems to develop and study the behavior of entirely new materials, pushing the boundaries of what is possible in engineering and technology.

Understanding the Trade-offs

While powerful, this technology is a strategic investment with specific considerations. It is not a universal solution for all heating applications.

High Initial Investment

Vacuum hot press furnaces are complex, precision-engineered systems. Their acquisition and installation represent a significant capital expenditure compared to standard atmospheric furnaces.

Specialized Operational Knowledge

Operating these systems effectively and safely requires skilled technicians. The processes of creating a vacuum, controlling pressure, and managing high temperatures demand specific expertise.

Longer Process Cycles

Achieving a deep vacuum and executing a controlled pressing and cooling cycle takes more time than a simple heat treatment process. This makes it better suited for high-value components rather than high-volume, low-cost production.

Making the Right Choice for Your Goal

The decision to use a vacuum hot press furnace should be driven by your end-goal for the material itself.

- If your primary focus is maximum strength and density: This is the definitive technology for eliminating porosity in ceramics and powdered metals for critical structural parts.

- If your primary focus is material purity and biocompatibility: The oxygen-free environment is essential for producing medical implants and high-purity electronic components.

- If your primary focus is bonding dissimilar materials: Use this for creating unique, high-performance composites that cannot be joined by conventional welding or brazing.

- If your primary focus is pioneering new materials: It is an indispensable tool for R&D, allowing you to test novel compositions under precisely controlled conditions.

Ultimately, a vacuum hot press furnace is the tool you turn to when standard materials and processes are no longer sufficient for your challenge.

Summary Table:

| Industry | Key Applications |

|---|---|

| Aerospace & Defense | Jet engine components, turbine blades, structural composites |

| Medical & Healthcare | Medical implants, surgical instrument coatings |

| Automotive & Energy | Engine parts, brake materials, turbine components |

| Electronics & Semiconductors | High-purity components, semiconductor bonding |

| Research & Development | New material development, advanced studies |

Elevate your material performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored vacuum hot press furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs in industries like aerospace, medical, automotive, and electronics. Contact us today to discuss how we can help you achieve superior results and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials