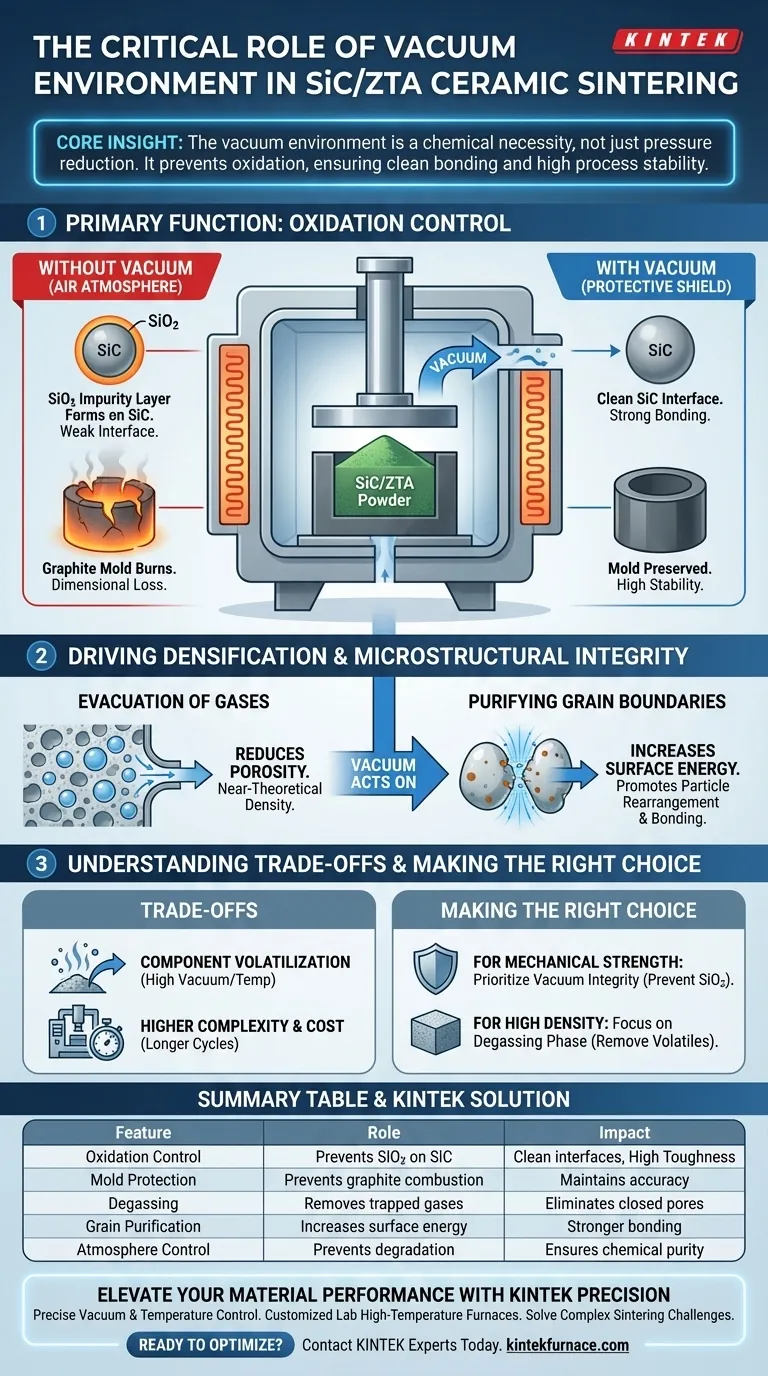

The vacuum environment acts as a critical protective shield and a facilitator of physical densification. Its primary function during the sintering of SiC/ZTA (Silicon Carbide/Zirconia Toughened Alumina) ceramics is to strictly control the chemical atmosphere, preventing the oxidation of non-oxide components and the processing equipment itself.

Core Insight: The vacuum environment is not merely about pressure reduction; it is a chemical necessity. It prevents the formation of brittle silica layers on SiC particles and protects graphite molds from combustion, ensuring clean interfacial bonding and high process stability.

The Primary Function: Oxidation Control

The most immediate "Surface Need" in sintering SiC/ZTA composites is preventing the chemical degradation of materials that are unstable in air at high temperatures.

Protecting Non-Oxide Components (SiC)

The inclusion of Silicon Carbide (SiC) in a ZTA matrix provides reinforcement, but SiC is highly susceptible to oxidation.

In the presence of oxygen, SiC particle surfaces form silica (SiO2) impurity layers. The vacuum environment effectively suppresses this reaction. By preventing this silica layer, the vacuum ensures a "clean" interface between the SiC and the ZTA matrix, which is vital for the mechanical transfer of stress and the overall toughness of the ceramic.

Preserving the Graphite Mold

Vacuum hot pressing almost exclusively utilizes graphite molds due to their thermal stability and electrical conductivity.

However, graphite oxidizes rapidly (burns) in air at sintering temperatures. The vacuum environment is essential to avoid oxidative damage to the mold. This preserves the dimensional accuracy of the component and prevents mold failure, ensuring process stability.

Driving Densification and Microstructural Integrity

Beyond protection, the vacuum serves a "Deep Need" by altering the thermodynamics and kinetics of the sintering process to maximize density.

Evacuation of Adsorbed and Volatile Gases

Raw ceramic powders naturally adsorb gases on their surfaces, and chemical reactions during heating can generate volatile byproducts.

If these gases are not removed, they become trapped, forming closed pores that weaken the final product. The vacuum environment actively extracts these residual impurities and adsorbed gases from the powder interstices. This reduction in porosity is decisive for achieving near-theoretical density.

Purifying Grain Boundaries

The vacuum aids in the volatilization or reduction of existing surface oxide layers on the raw particles.

By cleaning the particle surfaces, the vacuum purifies grain boundaries and increases surface energy. Higher surface energy improves the "sintering driving force," promoting particle rearrangement and stronger bonding between the SiC and ZTA grains.

Understanding the Trade-offs

While a vacuum environment is critical for SiC/ZTA, it introduces specific processing constraints that must be managed.

Component Volatilization

A vacuum lowers the boiling point/sublimation point of materials.

If the vacuum level is too high (pressure is too low) relative to the temperature, constituents with high vapor pressures may decompose or volatilize rather than sinter. While SiC and ZTA are generally stable, accurate control of the vacuum level is required to prevent surface degradation or stoichiometry shifts in the ceramic matrix.

Complexity and Cost

Vacuum hot pressing is inherently a batch process that requires sophisticated sealing and pumping systems.

Unlike continuous atmospheric sintering, the cycle times are longer and the equipment is significantly more expensive. This makes the process best suited for high-performance applications where material quality justifies the increased operational overhead.

Making the Right Choice for Your Goal

When configuring your sintering parameters for SiC/ZTA ceramics, align your vacuum strategy with your specific material objectives.

- If your primary focus is Mechanical Strength: Prioritize vacuum integrity to prevent silica layer formation on SiC, ensuring maximum interfacial bonding strength.

- If your primary focus is High Density: Focus on the vacuum's role in the "degassing" phase to fully evacuate adsorbed gases before the pores close off.

The vacuum environment is the fundamental enabler that transforms reactive powders into a chemically pure, structurally dense high-performance composite.

Summary Table:

| Feature | Role in SiC/ZTA Sintering | Impact on Final Ceramic |

|---|---|---|

| Oxidation Control | Prevents SiO2 formation on SiC particles | Ensures clean interfaces and high toughness |

| Mold Protection | Prevents graphite mold combustion | Maintains dimensional accuracy and stability |

| Degassing | Removes adsorbed gases and volatiles | Eliminates closed pores for near-theoretical density |

| Grain Purification | Increases surface energy of particles | Promotes stronger bonding and faster sintering |

| Atmosphere Control | Prevents degradation of non-oxides | Ensures chemical purity of the composite matrix |

Elevate Your Material Performance with KINTEK Precision

Achieving near-theoretical density in SiC/ZTA ceramics requires precise control over vacuum and temperature parameters. KINTEK provides industry-leading Vacuum, Hot Press, and CVD systems designed to solve your most complex sintering challenges. Backed by expert R&D and world-class manufacturing, our customizable lab high-temperature furnaces empower researchers and manufacturers to produce chemically pure, high-performance composites with ease.

Ready to optimize your sintering process?

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a vacuum hot press sintering furnace considered superior to atmospheric sintering for preparing high-purity dense magnesium oxide? Achieve Maximum Density and Purity

- What is the primary function of the vacuum environment in a vacuum hot press furnace during the sintering of graphite flake/copper composites? Ensure High-Performance Thermal Conductivity

- How does the vacuum environment facilitate the densification of ZnS ceramics? Unlock High-Performance Liquid Sintering

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- Why is secondary processing using a hydraulic press and a sintering furnace necessary for aluminum matrix composites?

- How does a vacuum hot pressing furnace contribute to high-hardness composites? Achieve Near-Theoretical Density

- What are the main components of a vacuum hot press furnace? Unlock Precision Material Processing

- How does temperature control at 950°C affect SiC/Cu-Al2O3 composites? Optimize Sintering for High Strength