A vacuum hot press sintering furnace outperforms atmospheric methods because it applies mechanical pressure simultaneously with heat in a controlled environment. While atmospheric sintering relies solely on thermal diffusion to bond particles, vacuum hot pressing utilizes external force to physically rearrange magnesium oxide (periclase) grains, achieving near-theoretical density at significantly lower temperatures while actively removing impurities.

Core Takeaway The superiority of vacuum hot pressing lies in its ability to decouple densification from temperature. By using pressure to force grain rearrangement and vacuum to extract volatiles, you achieve a denser, purer material structure without the excessive heat that causes abnormal grain growth in atmospheric sintering.

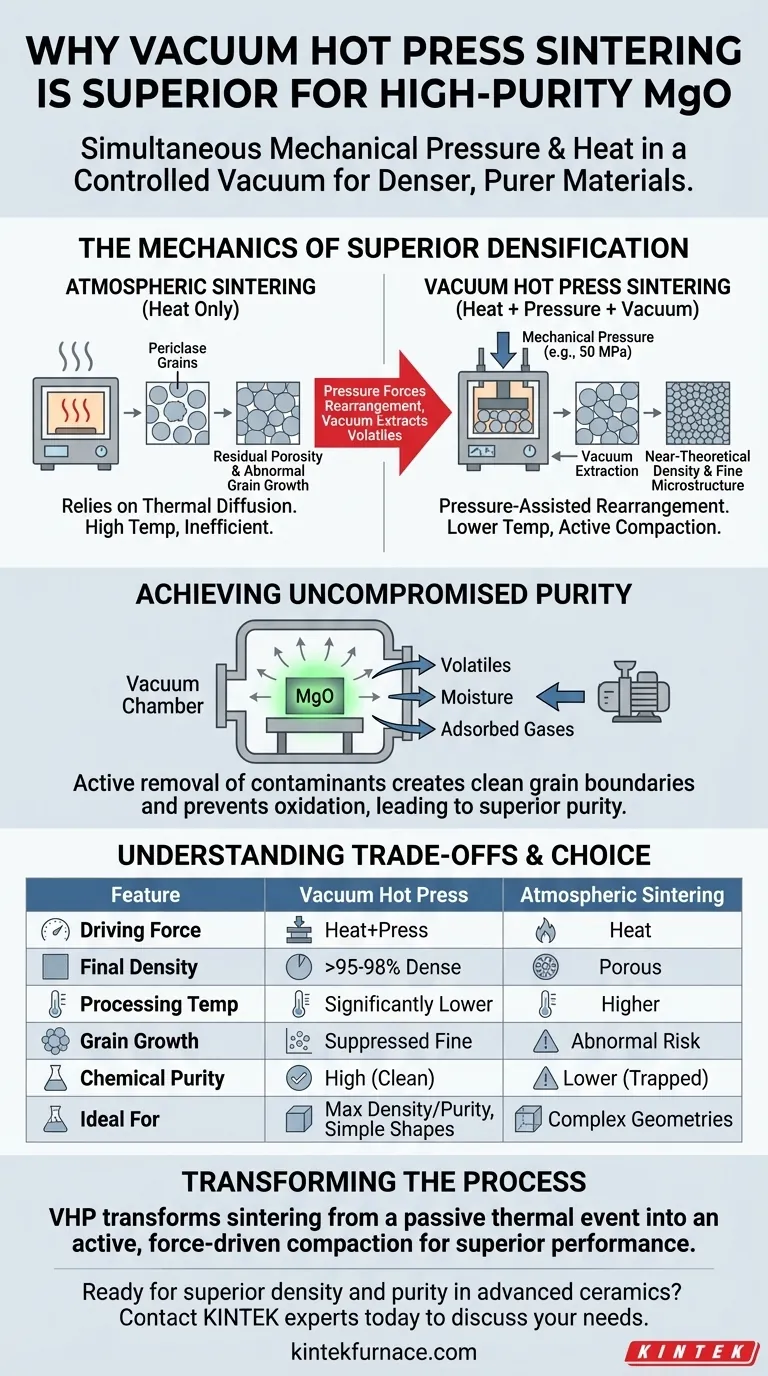

The Mechanics of Superior Densification

The Role of Mechanical Pressure

In atmospheric sintering, you rely on high temperatures to induce densification, which can be inefficient for difficult-to-sinter materials. A vacuum hot press applies mechanical pressure (e.g., 50 MPa) during the heating stage. This external force significantly increases the rearrangement rate of periclase grains, physically closing gaps that thermal energy alone cannot easily bridge.

Lower Temperatures, Better Microstructure

Because mechanical pressure provides an additional driving force, densification occurs at temperatures significantly lower than those required for atmospheric sintering. Lower processing temperatures are critical because they suppress abnormal grain growth. This results in a fine-grained microstructure, which directly correlates to higher hardness and fracture toughness.

Elimination of Micro-Pores

Atmospheric sintering often leaves residual porosity inside the material. The pressure-assisted method effectively eliminates micro-pores located in powder gaps and grain boundaries. This leads to a relative density that can exceed 95% to 98%, levels that are often unattainable with pressureless atmospheric methods.

Achieving Uncompromised Purity

Active Removal of Volatiles

High-purity magnesium oxide requires chemically clean grain boundaries. The vacuum environment actively removes adsorbed gases, moisture, and volatiles from the powder surfaces before sintering initiates. In an atmospheric furnace, these contaminants can become trapped within the closed pores, degrading the material's final properties.

Prevention of Contamination

Operating in a vacuum eliminates the presence of reactive gases found in air, such as oxygen and carbon dioxide. This prevents unwanted chemical reactions, oxidation of reinforcement phases, or the formation of oxide inclusions. The result is a "clean" atmosphere that improves the wettability between the matrix and any reinforcement phases, facilitating strong interfacial bonding.

Understanding the Trade-offs

Complexity vs. Quality

While vacuum hot pressing yields superior material properties, it introduces higher process complexity compared to atmospheric sintering. Atmospheric furnaces are generally simpler and allow for continuous processing. Vacuum hot pressing is typically a batch process that requires precise management of vacuum levels, hydraulic pressure, and thermal gradients.

Geometry Constraints

The application of mechanical pressure generally limits the geometry of the final product. Vacuum hot pressing is ideal for simple shapes like plates, disks, or cylinders. If your project requires complex, net-shape components with intricate geometries, atmospheric sintering (potentially followed by Hot Isostatic Pressing) might be a necessary logistical compromise despite the lower initial density.

Making the Right Choice for Your Goal

To ensure you select the correct processing method for your specific application, consider the following:

- If your primary focus is maximum density and mechanical strength: Choose vacuum hot pressing. The mechanical pressure is essential for eliminating micro-pores and achieving high fracture toughness.

- If your primary focus is ultra-high chemical purity: Choose vacuum hot pressing. The active removal of volatiles and isolation from atmospheric contaminants ensures the cleanest possible grain boundaries.

- If your primary focus is complex part geometry: Acknowledge that atmospheric sintering may be required for shaping, but be prepared for lower density or the need for secondary post-processing.

Vacuum hot pressing transforms the sintering process from a passive thermal event into an active, force-driven compaction that guarantees superior material performance.

Summary Table:

| Feature | Vacuum Hot Press Sintering | Atmospheric Sintering |

|---|---|---|

| Driving Force | Heat + Mechanical Pressure | Heat Only |

| Final Density | >95-98% (Near-Theoretical) | Lower (Residual Porosity) |

| Processing Temp | Significantly Lower | Higher |

| Grain Growth | Suppressed (Fine Microstructure) | Risk of Abnormal Growth |

| Chemical Purity | High (Volatiles & Contaminants Removed) | Lower (Risk of Trapped Impurities) |

| Ideal For | Maximum Density/Purity, Simple Shapes | Complex Geometries, Simpler Process |

Ready to achieve superior density and purity in your advanced ceramics?

For projects requiring maximum performance from materials like magnesium oxide, the controlled environment of a vacuum hot press is essential. Backed by expert R&D and manufacturing, KINTEK offers a range of high-temperature furnaces, including customizable Vacuum Hot Press systems, designed to meet your unique research and production needs.

Contact our experts today to discuss how our sintering solutions can enhance your material's properties.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- What is the role of the temperature control system in a vacuum furnace? Achieve Precise Material Transformations

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance