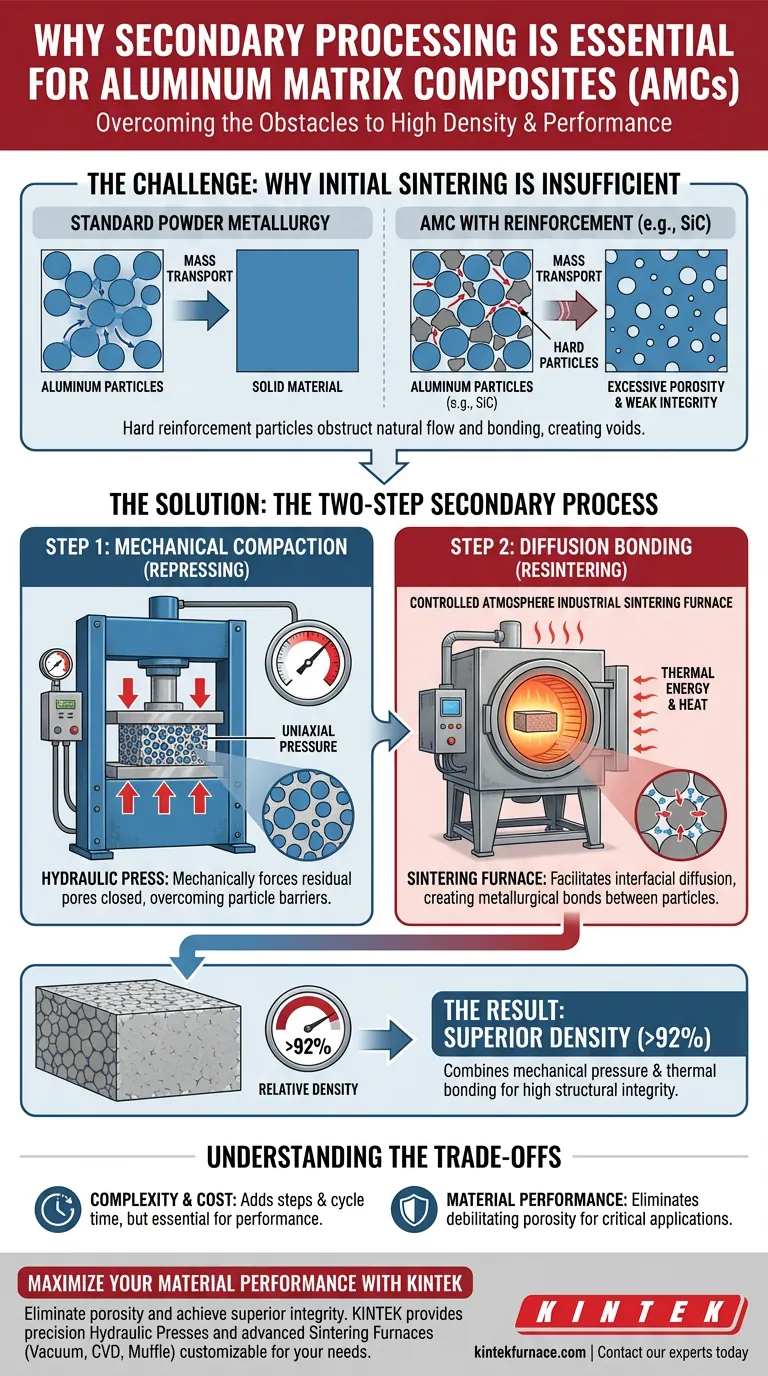

Secondary processing is necessary for Aluminum Matrix Composites (AMCs) because the addition of hard reinforcement particles, such as silicon carbide, physically obstructs the natural flow and bonding of the aluminum matrix.

Initially sintered materials often retain excessive porosity because these hard particles hinder mass transport. To correct this, a "repressing and resintering" strategy is required: the hydraulic press mechanically forces residual pores closed, while the sintering furnace facilitates the interfacial diffusion needed to lock in a relative density exceeding 92%.

The Core Mechanics of Densification Hard reinforcement particles act as physical barriers within the soft metal matrix, preventing standard sintering from achieving full solidity. Secondary processing decouples the solution: it uses mechanical force to crush voids and thermal energy to bond the material at the molecular level.

The Challenge: Why Initial Sintering is Insufficient

The Obstruction of Mass Transport

In standard powder metallurgy, metal particles fuse together through a process called mass transport. However, when you add hard particles like silicon carbide (SiC) to aluminum, these particles physically get in the way.

The Problem of Residual Porosity

Because the hard particles effectively "prop open" the structure, the aluminum cannot flow freely to fill all gaps.

Consequently, materials that have only undergone an initial sinter often suffer from excessive porosity. This porosity acts as a defect, significantly weakening the structural integrity of the final composite.

The Solution: The Two-Step Secondary Process

Step 1: Mechanical Compaction (Hydraulic Press)

The first phase of secondary processing involves repressing. A hydraulic press applies high, uniaxial pressure to the semi-sintered part.

This pressure is purely mechanical. Its primary function is to forcibly close the open pores that remained after the initial heating. The force overcomes the friction and physical barriers presented by the hard silicon carbide particles.

Step 2: Diffusion Bonding (Sintering Furnace)

Mechanical compaction brings the particles close together, but they are not yet chemically fused. This is where resintering in a furnace becomes critical.

The application of heat triggers interfacial diffusion. Atoms migrate across the boundaries between the aluminum and the reinforcement particles, creating a true metallurgical bond.

The Result: Superior Density

By combining these two distinct forces—mechanical pressure followed by thermal bonding—the material can achieve a relative density of over 92%. This level of density is rarely achievable through primary sintering alone when high volumes of reinforcement particles are present.

Understanding the Trade-offs

Process Complexity vs. Material Performance

Secondary processing introduces additional steps, equipment costs, and cycle time compared to a single-shot process. However, omitting these steps results in a material dominated by voids and poor mechanical strength.

The Risk of Oxidation

While the hydraulic press addresses porosity, the subsequent heating phase introduces the risk of oxidation. As noted in the broader context of sintering, aluminum oxidizes readily.

If the secondary sintering furnace does not maintain a controlled atmosphere (such as a vacuum or inert gas), oxides may form on particle surfaces. These oxides inhibit the very diffusion bonding the furnace is meant to promote.

Making the Right Choice for Your Project

The necessity of secondary processing depends entirely on the mechanical requirements of your final component.

- If your primary focus is high structural integrity: You must employ secondary repressing and resintering to eliminate porosity and push relative density above 92%.

- If your primary focus is cost reduction for non-critical parts: You might rely on initial sintering, accepting that the material will retain voids and possess lower strength.

Ultimately, secondary processing is not an optional refinement but a fundamental requirement for creating high-performance aluminum matrix composites that are free of debilitating porosity.

Summary Table:

| Process Phase | Equipment | Primary Function | Key Outcome |

|---|---|---|---|

| Repressing | Hydraulic Press | Mechanical Compaction | Forces residual pores closed |

| Resintering | Sintering Furnace | Interfacial Diffusion | Creates metallurgical bonds |

| Final Result | Combined System | Densification | Relative density > 92% |

Maximize Your Material Performance with KINTEK

Eliminate porosity and achieve superior structural integrity in your Aluminum Matrix Composites. KINTEK provides the precision equipment necessary for advanced secondary processing. Backed by expert R&D and manufacturing, we offer high-performance Hydraulic Presses and a wide range of lab high-temp furnaces, including Vacuum, CVD, and Muffle systems, all customizable to your specific density requirements.

Ready to elevate your composite manufacturing? Contact our experts today to find the perfect sintering and pressing solution for your lab!

Visual Guide

References

- A Wasik, M. Madej. Sustainability in the Manufacturing of Eco-Friendly Aluminum Matrix Composite Materials. DOI: 10.3390/su16020903

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a hot press machine used for? From custom apparel to aerospace components

- Why is a vacuum essential for TiAl/Ti6Al4V hot pressing? Unlock High-Performance Metallurgical Bonding

- How are hot press furnaces involved in semiconductor manufacturing? Essential for Wafer Bonding in 3D ICs

- How does a Vacuum Hot Pressing (VHP) furnace prepare high-performance P-type Mg3Sb2 thermoelectric materials?

- What are the technical advantages of using a Spark Plasma Sintering (SPS) system for Barium Titanate ceramics?

- How does a vacuum press machine work in shaping metals? Achieve Precision Metal Forming with Uniform Pressure

- What are the key advantages of hot pressing in terms of material quality? Achieve Superior Density and Purity for High-Performance Materials

- What are the functions of high-pressure compaction and the 500°C hardening process? Achieve Target Stability