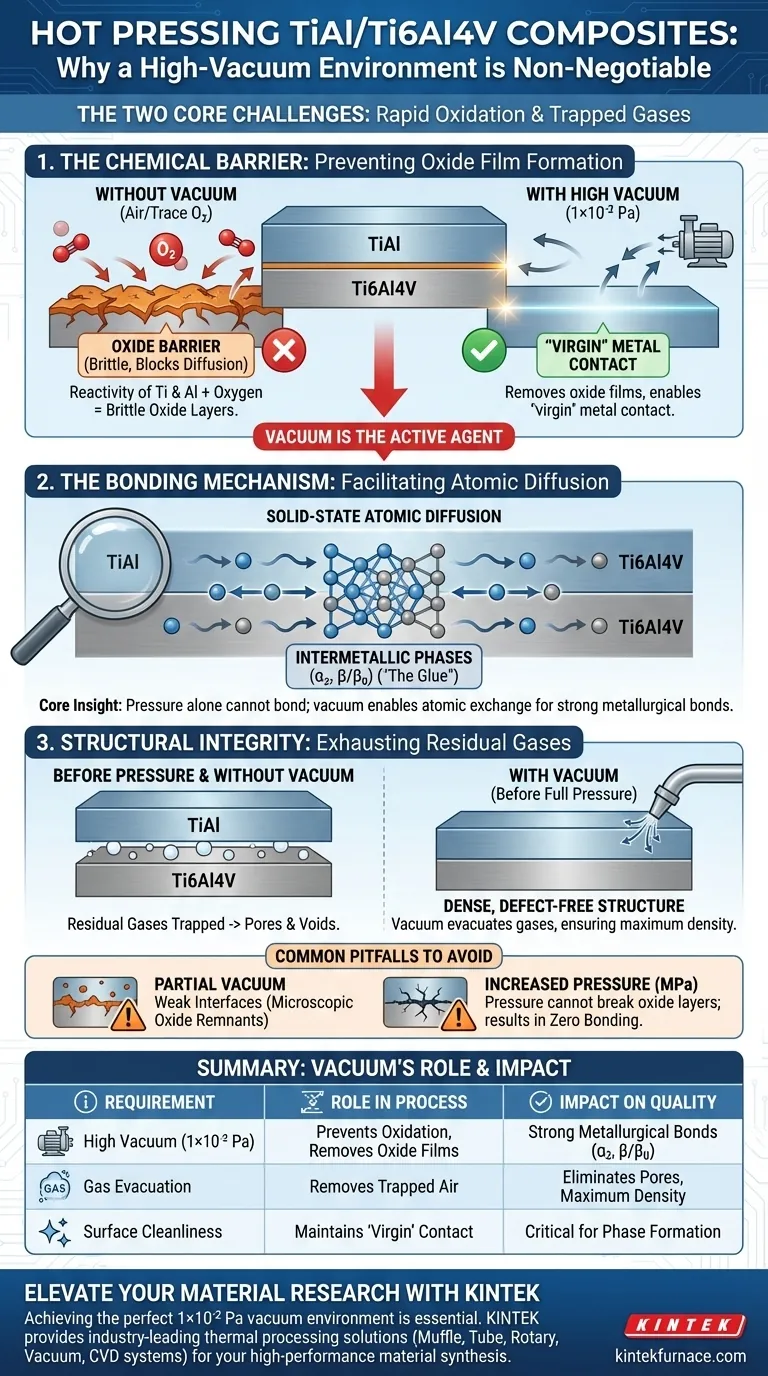

A high-vacuum environment is the non-negotiable prerequisite for the successful hot pressing of TiAl/Ti6Al4V layered composites. It serves two simultaneous functions: it strictly prevents the rapid oxidation of reactive titanium and aluminum elements at high temperatures, and it physically evacuates trapped gases to ensure a dense, defect-free structure. Without this environment, metallurgical bonding is chemically impossible.

The Core Insight High mechanical pressure alone cannot bond these materials; the interface must be chemically clean. The vacuum removes oxide film barriers, allowing "virgin" metal surfaces to touch directly. This contact is the only way to enable the atomic diffusion necessary to create strong intermetallic compound phases.

The Chemical Barrier: Preventing Oxidation

The Reactivity of Titanium and Aluminum

Titanium (Ti) and Aluminum (Al) are highly reactive elements, particularly when exposed to the high temperatures (e.g., 1000°C) required for hot pressing.

In the presence of even trace amounts of oxygen, these metals instantly form stable, brittle oxide layers.

Removing the Oxide Film

A high vacuum (typically 1×10⁻² Pa) is required to prevent these oxide films from forming or to destabilize existing thin films.

This environment ensures that the surfaces of the stacked layers remain as "virgin metal" rather than ceramic-like oxides.

Why "Virgin" Contact Matters

Oxide layers act as a diffusion barrier, physically blocking atoms from moving between layers.

By maintaining a vacuum, you ensure that raw metal touches raw metal, which is the foundational requirement for any subsequent bonding.

The Bonding Mechanism: Enabling Atomic Diffusion

Facilitating Interlayer Transport

Once the oxide barrier is removed, the vacuum environment allows for effective solid-state atomic diffusion between the TiAl and Ti6Al4V layers.

This diffusion is not merely about sticking layers together; it is about exchanging atoms to create a continuous material.

Formation of Intermetallic Phases

The goal of this diffusion is to form specific intermetallic compound phases, such as α₂ and β/β₀ phases.

These phases act as the "glue" that creates a robust metallurgical bond, ensuring the composite acts as a single structural unit rather than a stack of separate sheets.

Structural Integrity: Eliminating Physical Defects

Exhausting Residual Gases

Before the layers are compressed under high mechanical pressure (e.g., 30 MPa), air and other volatiles are naturally trapped between the sheets.

The vacuum environment evacuates these residual gases before the material creates a seal, preventing them from becoming permanently trapped.

Ensuring Material Density

If these gases are not removed, they form pores and voids within the composite.

A vacuum ensures the final material is dense and free of gas pore defects, which is critical for maintaining mechanical strength and fatigue resistance.

Common Pitfalls to Avoid

The "Partial Vacuum" Risk

Achieving a "rough" vacuum is often insufficient; if the pressure is not low enough (e.g., significantly higher than 1×10⁻² Pa), partial oxidation can still occur.

This results in "weak interfaces" where bonding looks successful visually but fails under stress due to microscopic oxide remnants.

Misunderstanding Pressure vs. Vacuum

It is a common error to believe that increasing mechanical pressure (MPa) can compensate for a poor vacuum.

Pressure closes gaps, but it cannot break through a continuous oxide layer; without a proper vacuum, you are simply pressing two oxidized surfaces together, resulting in zero metallurgical bonding.

Making the Right Choice for Your Goal

To ensure the integrity of your TiAl/Ti6Al4V composites, adhere to the following principles:

- If your primary focus is Interface Strength: Prioritize reaching and maintaining a vacuum of at least 1×10⁻² Pa to guarantee the formation of α₂ and β/β₀ phases.

- If your primary focus is Defect Elimination: Ensure the vacuum is applied before full mechanical pressure is exerted to allow residual interlayer gases to escape completely.

Ultimately, the vacuum is not just an environmental condition; it is the active agent that transforms stacked sheets into a unified high-performance composite.

Summary Table:

| Requirement | Role in Process | Impact on Composite Quality |

|---|---|---|

| High Vacuum (1×10⁻² Pa) | Prevents oxidation & removes oxide films | Enables atomic diffusion for strong metallurgical bonds |

| Gas Evacuation | Removes trapped air between layers | Eliminates pores and voids for maximum density |

| Surface Cleanliness | Maintains "virgin" metal contact | Allows formation of critical α₂ and β/β₀ phases |

| Mechanical Pressure | Closes physical gaps | Compresses layers into a unified structural unit |

Elevate Your Material Research with KINTEK

Achieving the perfect 1×10⁻² Pa vacuum environment is essential for the integrity of TiAl/Ti6Al4V composites. KINTEK provides industry-leading thermal processing solutions designed to meet these rigorous standards. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to your specific laboratory needs.

Don't let oxidation compromise your results. Contact our specialists today to find the ideal vacuum furnace for your high-performance material synthesis.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is it necessary to treat graphite molds containing mixed powders in a vacuum drying oven before vacuum hot press sintering? Prevent Porosity and Ensure Maximum Density

- What is a vacuum hot press? Achieve Ultimate Material Purity and Density

- What is the role of sacrificial inserts in the Spark Plasma Sintering (SPS) process? Master Complex Geometry Design

- What functions does a graphite mold perform? Unlock Superior Densification in Vacuum Hot Pressing

- How does a Spark Plasma Sintering (SPS) system compare to traditional furnaces for Al2O3-TiC ceramics?

- What is the core advantage of using a Hot Pressing Sintering (HPS) furnace? Enhance SiC/YAG Ceramic Density & Strength

- How does hot pressing minimize workpiece deformation? Achieve Precision with Lower Heat and Pressure

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties