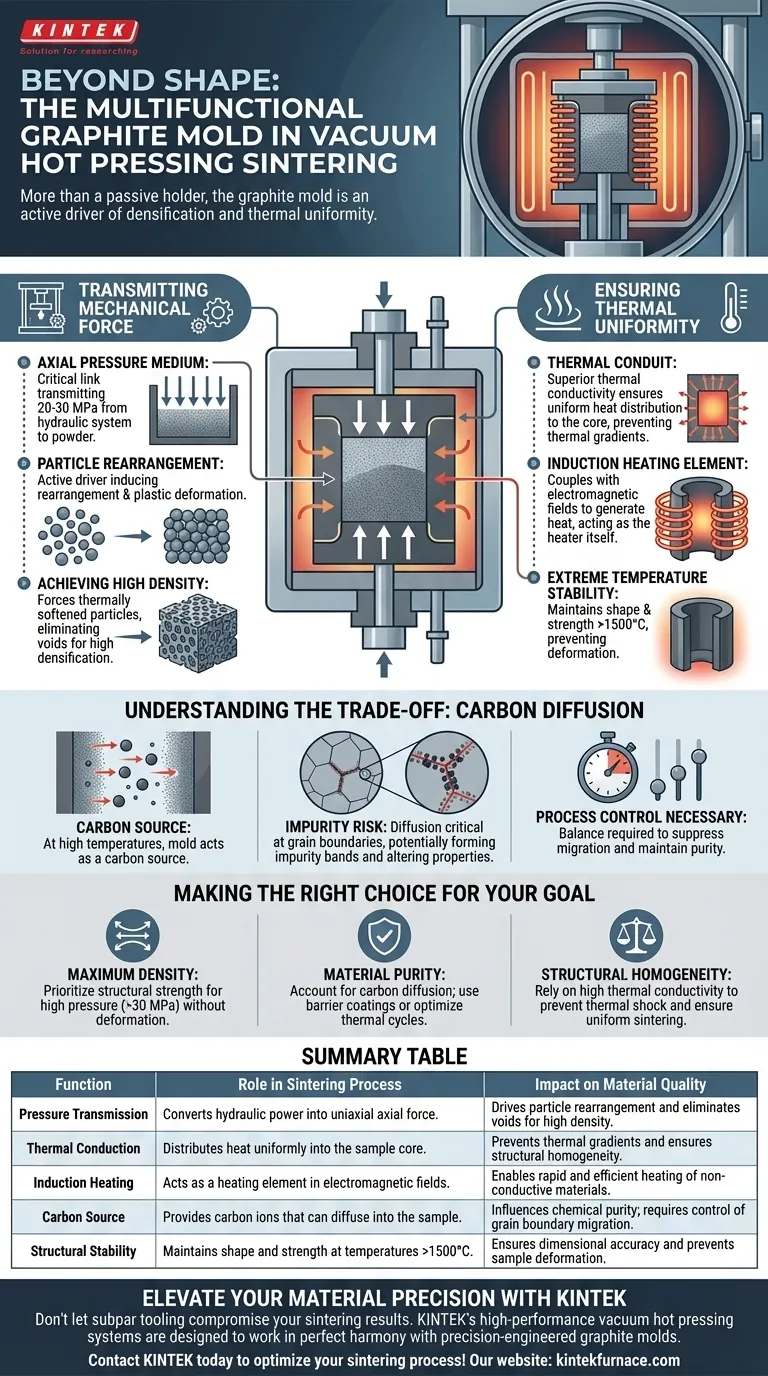

Beyond merely defining geometry, a graphite mold functions as the primary interface for transferring both mechanical force and thermal energy to the sample. It acts as a robust transmission vessel that converts hydraulic power into material densification while ensuring the uniform heat distribution necessary for structural integrity.

Core Insight The graphite mold is not a passive shape-holder; it is an active tool responsible for driving densification through precise pressure transmission and thermal conduction. Its ability to maintain structural stability under extreme heat directly dictates whether the material achieves a dense, uniform microstructure or suffers from porosity and defects.

Transmitting Mechanical Force for Densification

The Medium for Axial Pressure

In vacuum hot pressing, the mold serves as the critical link between the machine's hydraulic system and the powder body. It must effectively transmit significant uniaxial pressure (often ranging from 20 to 30 MPa) directly to the material.

Driving Particle Rearrangement

This transmission of pressure is not static; it is an active driver of the sintering process. The force applied by the mold induces particle rearrangement and plastic deformation within the powder.

Achieving High Density

By forcing particles closer together while they are thermally softened, the mold facilitates the elimination of voids. This mechanical assistance is essential for achieving high densification that thermal sintering alone cannot provide.

Ensuring Thermal Uniformity

Acting as a Thermal Conduit

Graphite possesses superior thermal conductivity, which allows the mold to act as an efficient heat transfer medium. It ensures that thermal energy is conducted uniformly into the center of the sample, preventing thermal gradients.

The Role of Heating Element

In specific setups, such as induction heating modes, the graphite mold effectively acts as the heating element itself. It couples with the electromagnetic field to generate heat, which is then transferred to the non-conductive ceramic or powder inside.

Stability at Extreme Temperatures

The mold must maintain its dimensional stability and strength at sintering temperatures that can exceed 1500°C. This high-temperature resistance prevents the mold from deforming, ensuring the sample retains its intended shape and density throughout the thermal cycle.

Understanding the Trade-offs: Carbon Diffusion

The Mold as a Carbon Source

While graphite is excellent for thermal and mechanical transfer, it introduces a chemical variable: carbon. At high temperatures, the mold acts as a carbon source, where carbon ions may diffuse into the sample.

Risk of Impurity Bands

This diffusion is particularly critical at grain boundaries, where carbon accumulation can form impurity bands. If left unchecked, this can alter the chemical composition and mechanical properties of the sintered material.

Necessity of Process Control

Operators must balance the benefits of graphite against this diffusion effect. Controlling grain growth and sintering time is often required to suppress carbon migration and maintain material purity.

Making the Right Choice for Your Goal

To optimize your vacuum hot pressing process, consider how the mold's functions align with your specific material requirements:

- If your primary focus is Maximum Density: Prioritize the mold's structural strength to ensure it can withstand and transmit the maximum required pressure (e.g., >30 MPa) without deformation.

- If your primary focus is Material Purity: You must account for the mold acting as a carbon source; consider using barrier coatings or optimizing thermal cycles to minimize carbon diffusion at grain boundaries.

- If your primary focus is Structural Homogeneity: Rely on the high thermal conductivity of the graphite to prevent thermal shock, ensuring the core and surface of the sample sinter at the same rate.

The graphite mold is the engine of the hot pressing process, bridging the gap between raw powder and a fully dense, high-performance solid.

Summary Table:

| Function | Role in Sintering Process | Impact on Material Quality |

|---|---|---|

| Pressure Transmission | Converts hydraulic power into uniaxial axial force. | Drives particle rearrangement and eliminates voids for high density. |

| Thermal Conduction | Distributes heat uniformly into the sample core. | Prevents thermal gradients and ensures structural homogeneity. |

| Induction Heating | Acts as a heating element in electromagnetic fields. | Enables rapid and efficient heating of non-conductive materials. |

| Carbon Source | Provides carbon ions that can diffuse into the sample. | Influences chemical purity; requires control of grain boundary migration. |

| Structural Stability | Maintains shape and strength at temperatures >1500°C. | Ensures dimensional accuracy and prevents sample deformation. |

Elevate Your Material Precision with KINTEK

Don't let subpar tooling compromise your sintering results. KINTEK’s high-performance vacuum hot pressing systems are designed to work in perfect harmony with precision-engineered graphite molds, ensuring maximum densification and thermal uniformity for your most demanding lab applications.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your unique research needs. Whether you are aiming for maximum density or high-purity grain structures, our technical team is ready to provide the right solution.

Contact KINTEK today to optimize your sintering process!

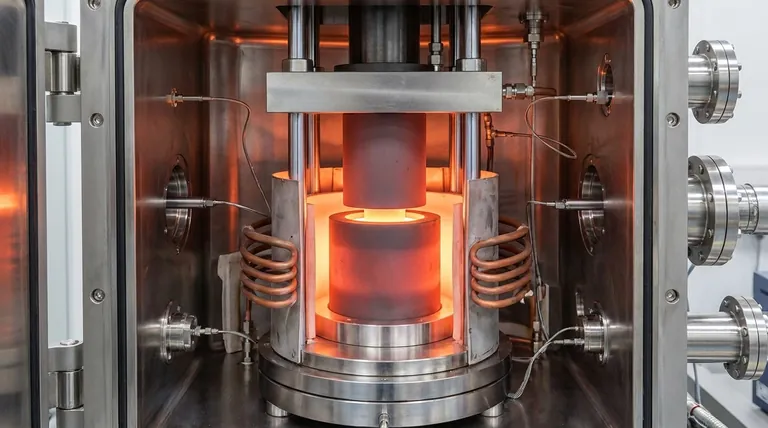

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does vacuum hot pressing or pressureless sintering equipment facilitate GdEuZrO preparation? Achieve High Density

- How does temperature precision in hot-pressing furnaces affect Pr3+:(Ca0.97Gd0.03)F2.03 ceramic microstructure?

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What are the core functions of a vacuum hot pressing furnace in the densification of Cr2AlC ceramics?

- What role does 30 MPa pressure play in SiC/Cu-Al2O3 sintering? Achieve 97.6% Density with Vacuum Hot Pressing

- What are the advantages of a high-pressure vacuum induction hot press furnace? Boost SiGe Thermoelectric Performance

- What is the impact of grain structure on material properties in hot pressing vs. cold compacting and sintering? Optimize Your Powder Metallurgy Process

- What roles do graphite molds play during the SPS of MgTiO3-CaTiO3? Achieve Rapid Densification and Precision