At its core, a vacuum hot press (VHP) is a specialized furnace that simultaneously applies high temperature, high pressure, and a vacuum environment to materials. This combination allows for the densification, bonding, or sintering of advanced materials like ceramics, metals, and composites, achieving properties that are impossible to attain through conventional heating methods alone.

The true value of a vacuum hot press is its ability to create exceptionally pure, dense, and strong materials. By removing air and other gases, the vacuum prevents oxidation and contamination, while heat and pressure work together to eliminate internal voids and create a solid, monolithic structure.

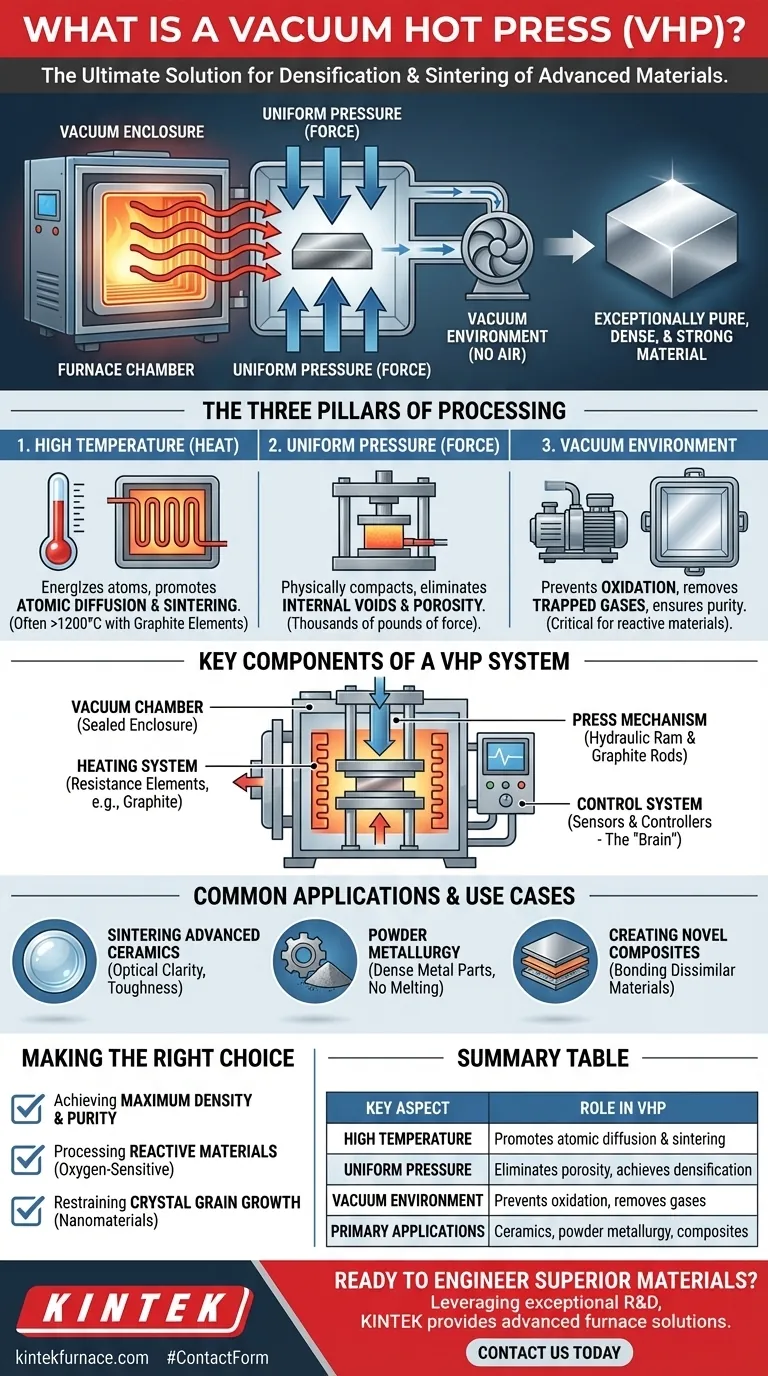

How a Vacuum Hot Press Works: The Three Pillars of Processing

The unique capabilities of a VHP stem from the precise, simultaneous control of three environmental factors: heat, pressure, and vacuum. Each plays a distinct and critical role in transforming raw powders or pre-formed parts into a highly engineered final product.

The Role of High Temperature (Heat)

A VHP is built around a high-temperature furnace, often utilizing graphite heating elements capable of reaching 1200°C or higher. This intense heat is not meant to melt the material but to energize its atoms.

This energy promotes atomic diffusion, allowing particles to bond and fuse together at their contact points. The process is known as sintering.

The Function of Uniform Pressure (Force)

Simultaneously, a hydraulic press mechanism exerts thousands of pounds of force on the material. This immense, uniform pressure physically compacts the material.

The primary goal of this pressure is to close the gaps and eliminate porosity (voids) between the initial particles. This is the key to achieving near-total densification and superior mechanical strength.

The Critical Importance of the Vacuum

The entire process takes place inside a sealed chamber where a vacuum generator removes the air. This low-pressure environment is arguably the most critical feature.

First, it prevents oxidation and other chemical reactions that would occur if reactive materials were heated in the presence of air. Second, it removes trapped gases from within the material itself, which would otherwise inhibit full densification and create structural defects.

Understanding the Key Components

A vacuum hot press is a system of integrated components, each with a specific function. Understanding these parts clarifies how the machine achieves such precise control.

The Vacuum Chamber

This is the sealed enclosure that contains the furnace, press, and the material being processed. It is designed to withstand both high internal temperatures and the external atmospheric pressure when a vacuum is drawn.

The Heating System

This system generates and controls the heat. It typically consists of resistance heating elements (like graphite) and a well-insulated chamber to ensure temperature uniformity and efficiency.

The Press Mechanism

Usually a hydraulic ram, this component applies the controlled, high force required for compaction. Graphite end rods are often used to transfer this force to the workpiece inside the hot zone of the furnace.

The Control System

This is the brain of the VHP. Advanced sensors and controllers monitor and regulate temperature, pressure, and vacuum levels throughout the process, ensuring the cycle is repeatable and tailored precisely to the material's requirements.

Common Applications and Use Cases

The ability to produce highly dense, pure materials makes the VHP indispensable in advanced research and specialized production environments.

Sintering Advanced Ceramics

VHPs are used to create high-performance and transparent ceramics. The process eliminates the microscopic pores that would otherwise scatter light or act as failure points, resulting in materials with exceptional optical clarity and mechanical toughness.

Powder Metallurgy

For refractory metals and other powdered alloys, the VHP process creates fully dense parts without having to melt the material. This is crucial for high-performance components used in aerospace and industrial applications.

Creating Novel Composite Materials

The VHP is essential for bonding dissimilar materials, such as carbon composites or ceramic-metal hybrids. The controlled environment ensures a strong bond between layers without degrading the constituent materials.

Making the Right Choice for Your Goal

Deciding if this technology fits your needs depends entirely on your desired material outcome.

- If your primary focus is achieving maximum density and purity: The VHP is the definitive tool, as it uniquely eliminates internal voids and prevents atmospheric contamination.

- If you are working with materials highly reactive to oxygen: The vacuum environment is non-negotiable, making the VHP essential for processing materials like certain metals, carbides, and nonmetal compounds.

- If your goal is to restrain crystal grain growth in nanomaterials: The combination of lower temperatures (relative to full melting) and high pressure helps produce dense nanostructured materials without coarsening the grains.

Ultimately, the vacuum hot press is a powerful tool for engineering materials at a fundamental level, enabling the creation of components that define the cutting edge of technology.

Summary Table:

| Key Aspect | Role in Vacuum Hot Pressing |

|---|---|

| High Temperature | Promotes atomic diffusion and particle bonding (sintering). |

| Uniform Pressure | Eliminates porosity and achieves near-total densification. |

| Vacuum Environment | Prevents oxidation and removes trapped gases for purity. |

| Primary Applications | Sintering advanced ceramics, powder metallurgy, creating composites. |

Ready to Engineer Superior Materials?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Contact us today to discuss how our vacuum hot press solutions can help you achieve maximum material density and purity for your most demanding applications.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?