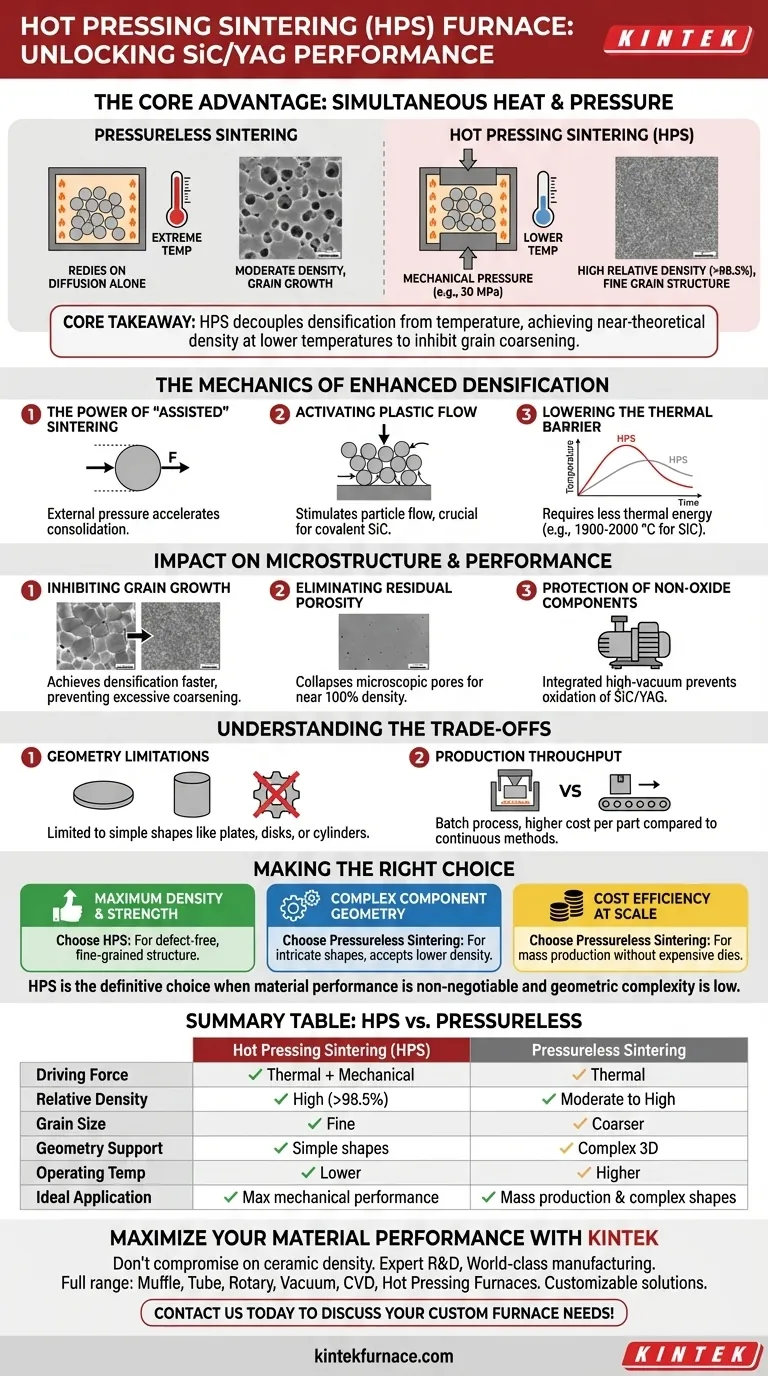

The core advantage of a Hot Pressing Sintering (HPS) furnace lies in its ability to apply external mechanical pressure simultaneously with high thermal energy. Unlike pressureless sintering, which relies solely on diffusion at extremely high temperatures, HPS utilizes this pressure (often around 30 MPa) to mechanically force particles together. This additional driving force enables SiC/YAG composite ceramics to achieve high relative densities (over 98.5%) at significantly lower temperatures.

Core Takeaway Hot Pressing Sintering decouples densification from temperature. By adding mechanical pressure, you can achieve near-theoretical density without the excessive heat that causes grain coarsening, resulting in a stronger, finer-grained ceramic microstructure.

The Mechanics of Enhanced Densification

The Power of "Assisted" Sintering

In traditional pressureless sintering, densification is driven strictly by the reduction of surface energy through atomic diffusion. HPS introduces a powerful external variable: uniaxial mechanical pressure. This pressure acts as a catalyst, physically accelerating the consolidation of the ceramic powder.

Activating Plastic Flow

The applied pressure stimulates plastic flow and particle rearrangement within the ceramic body. This mechanism is particularly effective for covalent materials like Silicon Carbide (SiC), which are notoriously difficult to densify using heat alone due to their low self-diffusion coefficients.

Lowering the Thermal Barrier

Because mechanical force is doing part of the work, the thermal energy required to bond the particles is reduced. HPS allows processing at temperatures (e.g., 1900-2000 °C for SiC) that are lower than what would be required for pressureless sintering to achieve the same density.

Impact on Microstructure and Performance

Inhibiting Grain Growth

One of the greatest enemies of ceramic strength is "abnormal grain growth," which typically occurs when materials are held at high temperatures for long periods to remove pores. Because HPS achieves densification faster and at lower temperatures, it effectively inhibits excessive grain coarsening.

Eliminating Residual Porosity

The axial pressure helps collapse microscopic pores that might otherwise remain trapped in the material. This leads to a microstructure with minimized defects and significantly improved mechanical properties, reaching near 100% of the theoretical density.

Protection of Non-Oxide Components

HPS systems are often integrated with high-vacuum environments. This combination not only aids densification but also removes residual gases from sintering necks, preventing the oxidation or decarburization of sensitive components like SiC or YAG during the heating phase.

Understanding the Trade-offs

Geometry Limitations

The primary downside of HPS is the geometric constraint. Because the pressure is usually applied uniaxially (from top and bottom), this method is generally limited to simple shapes like plates, disks, or cylinders. Complex geometries with undercuts or intricate internal features are better suited for pressureless atmosphere sintering.

Production Throughput

HPS is typically a batch process involving heavy graphite dies and longer cycle times compared to continuous sintering methods. While the material quality is superior, the production rate is generally lower and the cost per part is higher.

Making the Right Choice for Your Goal

To determine if HPS is the correct solution for your specific SiC/YAG application, evaluate your priorities:

- If your primary focus is Maximum Density and Strength: Choose Hot Pressing Sintering. The mechanical pressure ensures a defect-free, fine-grained structure that pressureless methods cannot easily match.

- If your primary focus is Complex Component Geometry: Choose Pressureless/Atmosphere Sintering. This allows for the densification of intricate shapes, provided you can accept slightly lower density or larger grain sizes.

- If your primary focus is Cost Efficiency at Scale: Choose Pressureless Sintering. The lack of expensive dies and the ability to process large batches simultaneously favor this method for mass production.

Ultimately, HPS is the definitive choice when material performance is non-negotiable and geometric complexity is low.

Summary Table:

| Feature | Hot Pressing Sintering (HPS) | Pressureless Sintering |

|---|---|---|

| Driving Force | Thermal energy + Mechanical pressure | Thermal energy (diffusion) |

| Relative Density | High (> 98.5% theoretical) | Moderate to High |

| Grain Size | Fine (inhibits grain coarsening) | Coarser (due to higher heat) |

| Geometry Support | Simple shapes (plates, disks) | Complex 3D geometries |

| Operating Temp | Lower required for densification | Higher required for densification |

| Ideal Application | Maximum mechanical performance | Mass production & complex shapes |

Maximize Your Material Performance with KINTEK

Don’t compromise on ceramic density. Whether you are developing SiC/YAG composite ceramics or advanced structural materials, KINTEK’s advanced sintering solutions provide the precision you need.

Backed by expert R&D and world-class manufacturing, we offer a full range of Muffle, Tube, Rotary, Vacuum, CVD systems, and Hot Pressing Furnaces, all fully customizable to your unique research or production requirements. Our systems are designed to minimize grain growth and eliminate porosity, ensuring your materials reach their near-theoretical potential.

Ready to elevate your ceramic processing? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Chang Zou, Xingzhong Guo. Microstructure and Properties of Hot Pressing Sintered SiC/Y3Al5O12 Composite Ceramics for Dry Gas Seals. DOI: 10.3390/ma17051182

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What core role does a vacuum hot press furnace play in the densification process of copper-carbon nanotube composites? Achieve High-Performance Cu-CNT Materials

- What are the advantages of SPS vs Hot Pressing for Ti-6Al-4V/HA? Maximize Bioactivity with Rapid Sintering

- How does a Hot Pressing (HP) furnace contribute to the densification of Titanium Diboride ceramics? Expert Solutions

- What are the advantages of using a Spark Plasma Sintering (SPS) system for UHTCs? Master Rapid Densification

- Why is a vacuum hot press furnace required for sintering CNT-Al composites? Optimize Density and Interface Bonding

- What temperature control features do vacuum hot press furnaces have? Achieve Precision in High-Temp Material Processing

- What materials are commonly processed in vacuum hot press furnaces? Unlock High-Performance Material Densification

- How does the pressure-assisted mechanism in a Vacuum Hot Press Furnace improve YAG ceramics? Unlock Optical Clarity