At the core of a vacuum hot press furnace's capability lies a sophisticated system designed for absolute thermal precision. These furnaces achieve this through a combination of insulated heating zones, high-accuracy temperature sensors like thermocouples, and advanced computer-controlled systems. Together, these components ensure uniform heat distribution across the workpiece and enable the execution of complex, repeatable thermal cycles.

A vacuum hot press furnace does more than just get hot. Its primary function is to provide an inert, contamination-free environment where temperature can be manipulated with extreme precision, a requirement for creating advanced materials with specific, predictable properties.

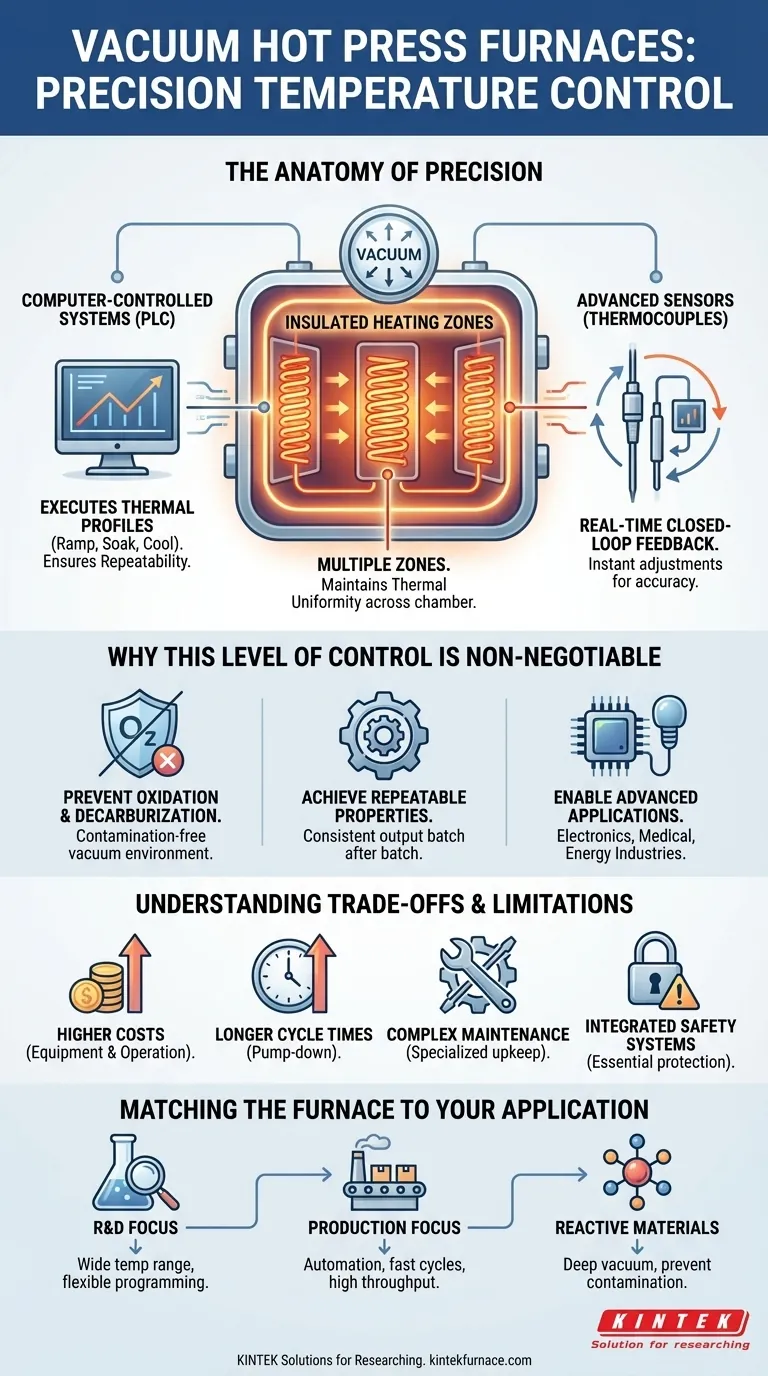

The Anatomy of Precision Temperature Control

Understanding how these furnaces manage heat is key to appreciating their value in advanced manufacturing and research. The control system is not a single component but a trio of integrated technologies working in unison.

Computer-Controlled Systems: The Brains of the Operation

The entire process is governed by a Programmable Logic Controller (PLC) or a dedicated computer system. This controller acts as the central brain, executing pre-programmed thermal profiles with high fidelity.

Operators can define precise heating rates (ramps), holding times (soaks), and cooling rates. This automation ensures that every production run is identical, which is critical for quality control and process validation.

Insulated Heating Zones: Ensuring Uniformity

A key challenge at high temperatures is maintaining thermal uniformity, preventing hot or cold spots that could ruin a component. Vacuum furnaces solve this with multiple, independently managed heating zones.

Each zone has its own heating elements and sensors. The central controller constantly adjusts the power to each zone, ensuring the entire chamber and the material within it maintain a consistent temperature as specified by the process recipe.

Advanced Temperature Sensors: The Feedback Loop

High-accuracy thermocouples are the "nerves" of the system. Placed strategically within the furnace chamber, they provide constant, real-time temperature data back to the controller.

This closed-loop feedback is what allows the system to react instantly to any deviation, making the precise temperature adjustments needed to stay on profile. This is essential for processes like sintering or crystal growth, where even minor temperature fluctuations can compromise the final product.

Why This Level of Control is Non-Negotiable

The combination of a vacuum environment and precise thermal control enables processes that are impossible in a standard atmosphere furnace.

Preventing Oxidation and Decarburization

The primary benefit of the vacuum is the removal of atmospheric gases, especially oxygen. This prevents unwanted chemical reactions like oxidation, which can degrade or destroy sensitive metallic and non-metallic materials at high temperatures.

Achieving Repeatable Material Properties

Processes like annealing, brazing, and sintering rely on specific thermal cycles to achieve the desired microstructure and material properties. The ability to program and repeat these cycles exactly is what ensures consistent, high-quality output batch after batch.

Enabling Advanced Applications

This technology is fundamental to producing components for the electronics, medical, and energy industries. From growing artificial gems to purifying high-temperature materials, the controlled environment is what makes these modern manufacturing processes possible.

Understanding the Trade-offs and Limitations

While powerful, vacuum hot press technology comes with specific considerations that must be weighed.

Higher Equipment and Operational Costs

These furnaces represent a significant capital investment compared to standard atmospheric furnaces. The complexity of the vacuum pumps, control systems, and chamber construction drives up the cost.

Longer Cycle Times

Achieving a high vacuum is not instantaneous. The "pump-down" time required to evacuate the chamber adds to the total cycle time, which can be a factor in high-volume production planning.

Complex Maintenance Requirements

Maintaining the integrity of the vacuum system is critical. Seals, pumps, and sensors require regular, specialized maintenance to prevent leaks and ensure reliable operation. This often requires more highly skilled technicians than a conventional furnace.

Integrated Safety Systems

Due to the high temperatures and energies involved, these furnaces are equipped with robust safety features. Systems like over-temperature alarms, water cooling interlocks, and overvoltage protection are not optional—they are essential for safe and reliable operation.

Matching the Furnace to Your Application

Choosing the right furnace configuration depends entirely on your end goal. The key is to match the furnace's capabilities to the specific demands of your material and process.

- If your primary focus is research and development: Prioritize a furnace with a wide operating temperature range (e.g., up to 2400°C) and highly flexible programming to explore different material behaviors.

- If your primary focus is high-volume production: Emphasize automation, fast cycle times (including pump-down), and robust, repeatable process control to maximize throughput and quality.

- If your primary focus is processing highly reactive materials: The quality of the vacuum system is paramount. Invest in a system capable of achieving the deep vacuum necessary to prevent any contamination.

Understanding these control features empowers you to select and utilize this technology to achieve superior material outcomes.

Summary Table:

| Feature | Description |

|---|---|

| Computer-Controlled Systems | Uses PLC or computers for precise heating, holding, and cooling cycles, ensuring repeatability and automation. |

| Insulated Heating Zones | Multiple zones with independent control to maintain thermal uniformity and prevent hot/cold spots. |

| Advanced Temperature Sensors | High-accuracy thermocouples provide real-time feedback for closed-loop control and instant adjustments. |

| Vacuum Environment | Removes oxygen to prevent oxidation and decarburization, enabling contamination-free processing. |

| Safety Systems | Includes over-temperature alarms, water cooling interlocks, and overvoltage protection for reliable operation. |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in R&D, high-volume production, or handling reactive materials, our expertise ensures superior thermal control and consistent results. Contact us today to discuss how our tailored solutions can enhance your material processing and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy