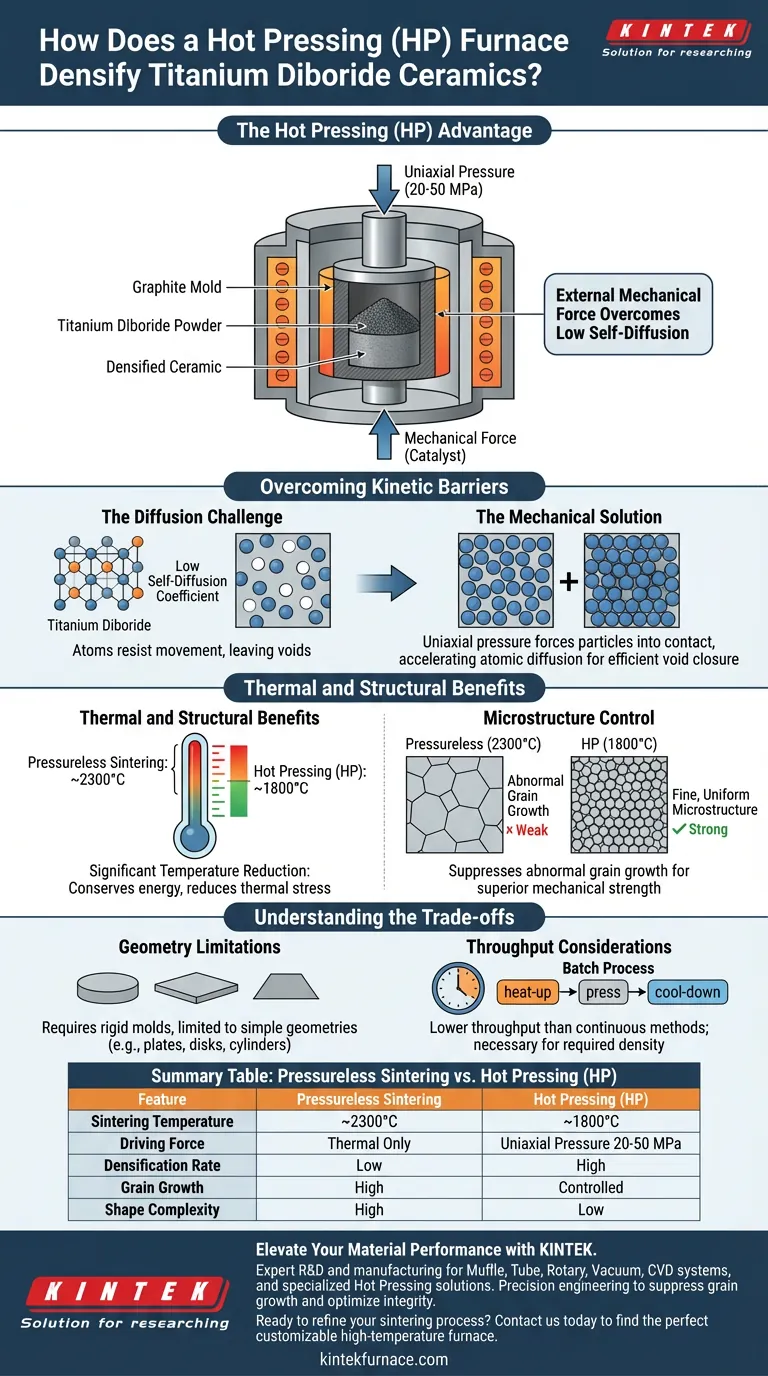

A Hot Pressing (HP) furnace drives densification by applying simultaneous uniaxial pressure to Titanium Diboride powder encased in a graphite mold. This external mechanical force, typically ranging from 20 to 50 MPa, acts as a catalyst to overcome the material's naturally low self-diffusion coefficient.

By substituting extreme thermal energy with mechanical force, Hot Pressing shifts the sintering requirements of Titanium Diboride, enabling high density at significantly lower temperatures while preserving structural integrity.

Overcoming Kinetic Barriers

The Diffusion Challenge

Titanium Diboride is inherently difficult to densify because its atomic structure resists movement. Under normal conditions, it possesses a low self-diffusion coefficient, meaning the atoms do not naturally rearrange themselves to fill voids and eliminate pores. Traditional sintering relies solely on thermal energy to drive this movement, often requiring excessive heat.

The Mechanical Solution

An HP furnace introduces a mechanical driving force to solve this kinetic problem. By applying uniaxial pressure directly to the powder, the furnace forces particles into closer contact. This physically accelerates atomic diffusion, ensuring that voids are closed more efficiently than thermal energy could achieve alone.

Thermal and Structural Benefits

Significant Temperature Reduction

Because pressure assists in the densification process, the thermal requirement drops drastically. While pressureless sintering of Titanium Diboride demands temperatures around 2300°C, Hot Pressing achieves comparable or better results at approximately 1800°C. This reduction conserves energy and reduces thermal stress on the equipment.

Microstructure Control

High temperatures often lead to a phenomenon known as abnormal grain growth, where crystals grow too large and degrade the material's strength. By sintering at 1800°C rather than 2300°C, Hot Pressing effectively suppresses abnormal grain growth. This results in a fine, uniform microstructure that is critical for the mechanical performance of the final ceramic.

Understanding the Trade-offs

Geometry Limitations

The application of uniaxial pressure requires rigid graphite molds. This limits the complexity of shapes you can produce; the process is best suited for simple geometries like plates, disks, or cylinders. Parts with complex features or undercuts cannot be effectively formed using this method.

Throughput Considerations

Hot Pressing is inherently a batch process involving heat-up, pressing, and cool-down cycles for specific mold sets. It generally has lower throughput compared to continuous pressureless sintering methods. However, for materials like Titanium Diboride, the trade-off is often necessary to achieve the required density.

Making the Right Choice for Your Goal

To determine if Hot Pressing is the correct approach for your Titanium Diboride application, consider your specific performance targets:

- If your primary focus is Maximum Density: Hot Pressing is essential to overcome low self-diffusion and eliminate porosity without reaching extreme temperatures.

- If your primary focus is Microstructural Integrity: The lower processing temperature (1800°C) is the best method to prevent grain coarsening and maintain mechanical strength.

Hot Pressing transforms the processing of Titanium Diboride from a thermal challenge into a controlled, mechanically assisted success.

Summary Table:

| Feature | Pressureless Sintering | Hot Pressing (HP) |

|---|---|---|

| Sintering Temperature | ~2300°C | ~1800°C |

| Driving Force | Thermal energy only | Uniaxial pressure (20-50 MPa) |

| Densification Rate | Low (due to low diffusion) | High (mechanical assistance) |

| Grain Growth | High (abnormal growth risk) | Controlled (fine microstructure) |

| Shape Complexity | High (complex geometries) | Low (simple disks/plates) |

Elevate Your Material Performance with KINTEK

Are you struggling to achieve full densification in advanced ceramics like Titanium Diboride? Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized Hot Pressing solutions tailored for your unique lab needs. Our precision engineering helps you suppress grain growth and optimize structural integrity at lower energy costs.

Ready to refine your sintering process? Contact us today to consult with our experts and find the perfect customizable high-temperature furnace for your research or production goals.

Visual Guide

References

- Xinran Lv, Gang Yu. Review on the Development of Titanium Diboride Ceramics. DOI: 10.21926/rpm.2402009

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does the application of mechanical pressure contribute to the vacuum hot pressing formation of TiAl/Ti6Al4V? Expert Analysis

- What is the function of a rigid mould in vacuum hot pressing? Master Structural Precision in Layered Composites

- What is the core function of a vacuum hot press sintering furnace? Unlock High-Performance TiCN Composite Synthesis

- What is the function of an infrared pyrometer in the SPS process of Ti-6Al-4Zr-4Nb? Precision Phase Control Explained

- Why is vacuum hot press sintering recommended over pressureless sintering? Achieve Peak Density for IZO Ceramic Targets

- Why is a high-vacuum environment required during SPS for transparent materials? Achieve Optical Purity

- How does a vacuum hot press work? Unlock Superior Material Density and Purity

- Why is a high vacuum essential for ZnS hot press sintering? Achieve Maximum Infrared Transmittance