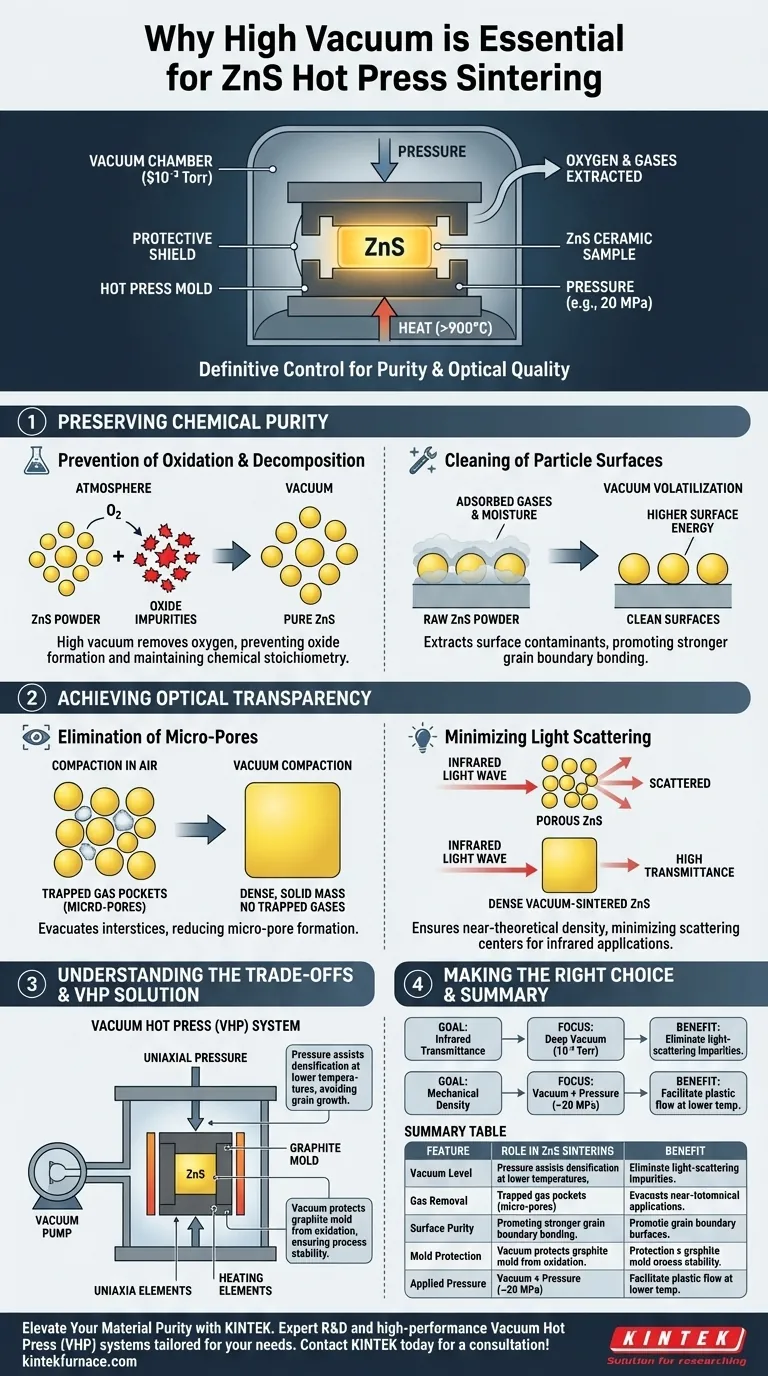

Maintaining a high vacuum environment during the hot press sintering of Zinc Sulfide (ZnS) is the definitive control measure required to prevent chemical degradation and ensure optical quality. Specifically, operating at vacuum levels around $10^{-3}$ Torr eliminates the presence of oxygen, preventing the oxidation and decomposition of the material while actively extracting trapped gases that would otherwise compromise the final ceramic structure.

The vacuum serves as a critical purification tool that directly impacts the optical performance of the ceramic. By evacuating trapped gases and preventing oxidation, the vacuum environment ensures the elimination of micro-pores, which is the deciding factor in minimizing light scattering and achieving high infrared transmittance.

Preserving Chemical Purity

Prevention of Oxidation and Decomposition

At the elevated temperatures required for sintering (often exceeding 900°C), Zinc Sulfide is highly susceptible to chemical instability.

High vacuum acts as a protective shield, removing atmospheric oxygen that would otherwise react with the ZnS powder. This prevents the formation of oxide impurities and ensures the material does not decompose, maintaining the chemical stoichiometry required for a pure final product.

Cleaning of Particle Surfaces

Raw ceramic powders often contain adsorbed gases, moisture, or volatile impurities on their surfaces.

A vacuum environment promotes the volatilization and extraction of these surface contaminants before the sintering process seals the material. This purifies the grain boundaries, creating higher surface energy that is more favorable for the bonding and densification of particles.

Achieving Optical Transparency

Elimination of Micro-Pores

The primary enemy of optical clarity in ceramics is porosity. Gases trapped between powder particles during densification create voids.

The vacuum environment effectively evacuates the air from powder interstices (the gaps between particles) prior to and during compaction. This prevents gas pockets from becoming trapped inside the solidifying mass, thereby reducing the formation of micro-pores in the final product.

Minimizing Light Scattering

For ZnS ceramics intended for use in infrared applications, internal structure is everything.

Micro-pores act as scattering centers for light waves, severely degrading transmission. By ensuring near-theoretical density through vacuum processing, you minimize these scattering centers. This is the decisive factor for ensuring the ceramic possesses the high transmittance required for infrared wavebands.

Understanding the Trade-offs

The Necessity of Mechanical Pressure

While a high vacuum is essential for purity, it is rarely sufficient on its own to achieve full density in ZnS ceramics.

Relying solely on vacuum sintering often requires excessively high temperatures to drive densification, which can lead to grain growth that hurts mechanical strength. The Vacuum Hot Press (VHP) method mitigates this by combining vacuum with uniaxial mechanical pressure (e.g., 20 MPa). This pressure assists particle rearrangement, allowing for densification at lower temperatures.

Equipment Stability

The vacuum does not only protect the ZnS; it also protects the processing equipment.

Hot press molds are frequently made of graphite, which oxidizes and degrades rapidly in air at high temperatures. The vacuum environment preserves the integrity of the graphite mold, preventing carbon contamination of the ceramic and ensuring a stable, repeatable process.

Making the Right Choice for Your Goal

To optimize your ZnS sintering process, align your vacuum parameters with your specific performance requirements:

- If your primary focus is Infrared Transmittance: Prioritize the depth of the vacuum ($10^{-3}$ Torr or better) to ruthlessly eliminate volatile impurities and adsorbed gases, as these are the primary sources of light-scattering micro-pores.

- If your primary focus is Mechanical Density: Ensure your process couples the vacuum environment with significant mechanical pressure (approx. 20 MPa) to facilitate plastic flow and particle rearrangement at lower thermal loads.

Ultimate success in ZnS sintering lies in using vacuum not just as an environment, but as an active tool to purify the microstructure for maximum optical clarity.

Summary Table:

| Feature | Role in ZnS Sintering | Benefit |

|---|---|---|

| Vacuum Level | $10^{-3}$ Torr or better | Prevents oxidation & material decomposition |

| Gas Removal | Evacuates interstices | Eliminates light-scattering micro-pores |

| Surface Purity | Volatilization of contaminants | Stronger grain boundary bonding & densification |

| Mold Protection | Prevents graphite oxidation | Ensures process stability & avoids carbon contamination |

| Applied Pressure | Mechanical compaction | Achieves theoretical density at lower temperatures |

Elevate Your Material Purity with KINTEK

Precise control over vacuum and pressure is the deciding factor in the optical quality of Zinc Sulfide ceramics. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Vacuum Hot Press (VHP) systems, Muffle, Tube, and CVD furnaces tailored for your unique lab and industrial needs.

Our customizable high-temperature solutions ensure the chemical stoichiometry and near-theoretical density required for advanced infrared applications.

Ready to optimize your sintering process? Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is it necessary to treat graphite molds containing mixed powders in a vacuum drying oven before vacuum hot press sintering? Prevent Porosity and Ensure Maximum Density

- What is the primary function of graphite foil within the FAST system? Optimize Your Sintering and Tooling Protection

- Why is a Vacuum Hot Press Sintering (VHPS) furnace preferred for AlxCoCrFeNi high-entropy alloys? Achieve 99% Density

- Why is a vacuum essential for TiAl/Ti6Al4V hot pressing? Unlock High-Performance Metallurgical Bonding

- What are the functions of high-pressure compaction and the 500°C hardening process? Achieve Target Stability

- How does tailored heat and pressure control benefit hot pressing? Achieve Superior Material Density and Strength

- What role do vacuum hot press furnaces play in advanced materials development? Forge High-Density, Pure Materials

- What materials are commonly processed in vacuum hot press furnaces? Unlock High-Performance Material Densification