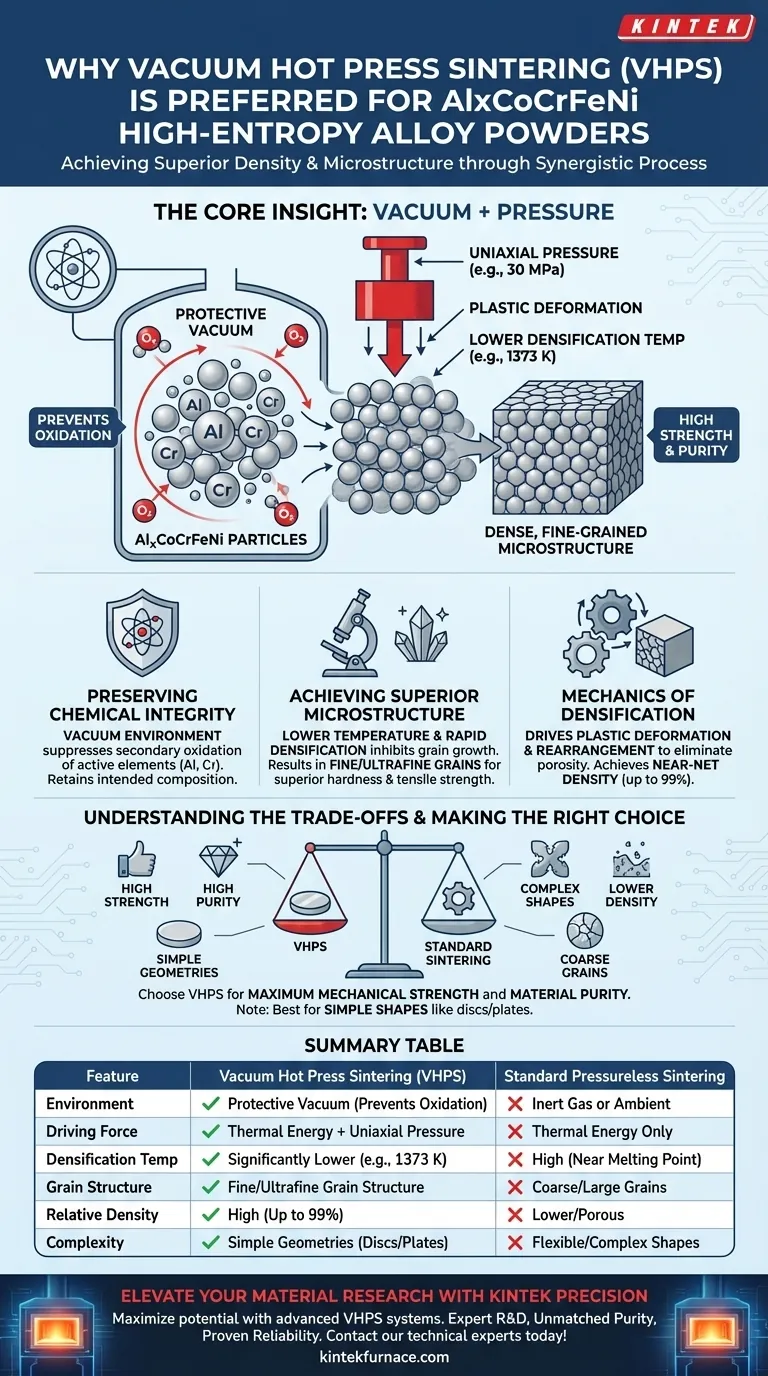

Vacuum Hot Press Sintering (VHPS) is preferred for processing AlxCoCrFeNi high-entropy alloys because it uniquely integrates a protective vacuum environment with simultaneous high temperature and uniaxial pressure. This combination allows for the densification of reactive powders at temperatures significantly lower than their melting points (e.g., 1373 K), preventing the oxidation of active elements like Aluminum and Chromium while inhibiting excessive grain growth.

The Core Insight: The distinct advantage of VHPS lies in its synergistic approach; the vacuum protects the alloy's chemistry, while the mechanical pressure forces densification through plastic deformation. This achieves a highly dense, fine-grained microstructure that is difficult to replicate with standard pressureless sintering or casting methods.

Preserving Chemical Integrity

Preventing Secondary Oxidation

The AlxCoCrFeNi alloy system contains highly active elements, specifically Aluminum (Al) and Chromium (Cr).

In standard sintering environments, these elements are prone to rapid oxidation, which degrades the material's mechanical properties.

The vacuum environment of a VHPS furnace effectively suppresses this secondary oxidation, ensuring the final bulk material retains its intended chemical composition and purity.

Achieving Superior Microstructure

Lowering Densification Temperature

Standard sintering relies heavily on thermal energy to induce diffusion, requiring extremely high temperatures to remove pores.

VHPS utilizes uniaxial pressure (e.g., 30 MPa) to mechanically force particles together.

This pressure-assisted mechanism significantly lowers the required temperature for densification, allowing the process to occur well below the melting point.

Inhibiting Grain Growth

High temperatures and long dwell times in standard processes inevitably lead to coarse, large grains, which can reduce material strength.

Because VHPS facilitates rapid densification at lower temperatures, it effectively inhibits excessive grain growth.

The result is a bulk material with a fine-grain or even ultrafine structure, which directly contributes to superior hardness and tensile strength.

The Mechanics of Densification

Driving Plastic Deformation

The application of continuous mechanical pressure forces powder particles to undergo plastic deformation and rearrangement.

This physical compression breaks down bridges between particles and fills voids that thermal energy alone might leave behind.

Eliminating Porosity

VHPS promotes diffusion creep and atomic diffusion bonding more effectively than pressureless methods.

This allows the material to achieve near-net density (up to 99%), effectively eliminating the porosity and casting defects often found in melting processes like arc melting.

Understanding the Trade-offs

Geometric Limitations

While VHPS produces superior material properties, the reliance on uniaxial pressure restricts the complexity of shapes you can produce.

The force is applied in one direction, making this method best for simple geometries like discs, plates, or cylinders, rather than complex 3D components.

Production Throughput

VHPS is typically a batch process, meaning it generally has a lower throughput compared to continuous sintering methods.

The cycle times, while shorter than some pressureless methods, still limit high-volume mass production capabilities.

Making the Right Choice for Your Goal

If you are deciding between VHPS and other consolidation methods for AlxCoCrFeNi alloys, consider your specific performance requirements:

- If your primary focus is mechanical strength: Choose VHPS to leverage fine-grain strengthening and high density for maximum hardness and tensile properties.

- If your primary focus is material purity: Choose VHPS to utilize the vacuum environment, which is critical for preventing the oxidation of Aluminum and Chromium.

- If your primary focus is complex geometry: You may need to consider alternative methods, as VHPS is limited to simple shapes due to the uniaxial pressure application.

VHPS offers the optimal balance of density, purity, and microstructural control for high-performance high-entropy alloys.

Summary Table:

| Feature | Vacuum Hot Press Sintering (VHPS) | Standard Pressureless Sintering |

|---|---|---|

| Environment | Protective Vacuum (Prevents Oxidation) | Inert Gas or Ambient |

| Driving Force | Thermal Energy + Uniaxial Pressure | Thermal Energy Only |

| Densification Temp | Significantly Lower (e.g., 1373 K) | High (Near Melting Point) |

| Grain Structure | Fine/Ultrafine Grain Structure | Coarse/Large Grains |

| Relative Density | High (Up to 99%) | Lower/Porous |

| Complexity | Simple Geometries (Discs/Plates) | Flexible/Complex Shapes |

Elevate Your Material Research with KINTEK Precision

Maximize the potential of your AlxCoCrFeNi high-entropy alloys with KINTEK’s advanced Vacuum Hot Press Sintering systems. Backed by expert R&D and world-class manufacturing, we provide customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of modern material science.

Why choose KINTEK?

- Expert Customization: Tailored furnace solutions for unique laboratory and industrial needs.

- Unmatched Purity: Achieve near-net density without the risk of oxidation.

- Proven Reliability: Trusted by leading researchers for high-temp lab applications.

Ready to transform your powder metallurgy workflow? Contact our technical experts today to discuss your specific requirements and get a custom quote!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the role of a high-strength graphite die in the vacuum hot press sintering of SiC ceramics? Essential Functions

- What are the main components of a vacuum hot press sintering furnace? Unlock Precision in Material Densification

- Why is vacuum press technology indispensable in modern metalworking? Unlock Precision and Quality in Metal Forming

- How does a Vacuum Hot Press Furnace facilitate Al-Ti-Zr synthesis? Achieve Near-Theoretical Material Density

- What roles do high-strength graphite molds play during the hot-pressing sintering of TiAl-SiC composites?

- Why are graphite molds selected for the vacuum hot press sintering of aluminum-based composites? Expert Insights

- What effect does mechanical pressure have on AZ31/UCF/AZ31 composite formation? Master VHP Densification

- What are the advantages of using hot pressing in manufacturing? Achieve Superior Quality and Precision