A high-strength graphite die serves as the critical structural and chemical interface during the vacuum hot press sintering of silicon carbide (SiC). It functions simultaneously as a heat-resistant container capable of withstanding extreme temperatures (around 1850°C) and a mechanical transmitter that delivers high pressures (up to 30 MPa) to densify the ceramic powder.

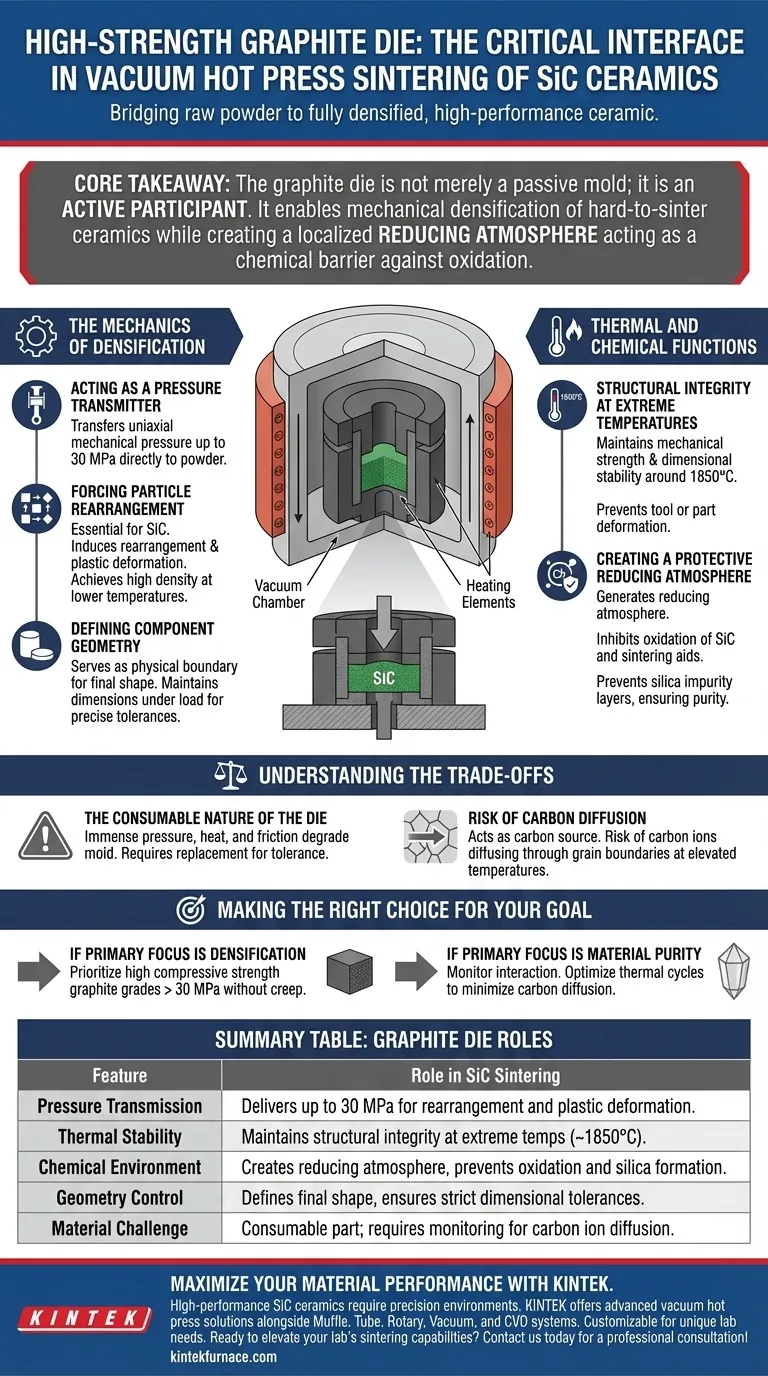

Core Takeaway: The graphite die is not merely a passive mold; it is an active participant in the sintering process. It enables the mechanical densification of hard-to-sinter ceramics while creating a localized reducing atmosphere that acts as a chemical barrier against oxidation.

The Mechanics of Densification

Acting as a Pressure Transmitter

In vacuum hot pressing, the graphite die acts as the primary transmission medium for the hydraulic system. It must effectively transfer uniaxial mechanical pressure—typically up to 30 MPa—directly to the internal ceramic powder.

Forcing Particle Rearrangement

This transmitted pressure is essential for densifying SiC, which is notoriously hard to sinter. The force applied by the die induces particle rearrangement and plastic deformation within the powder.

This mechanical assist allows the material to achieve high density at temperatures lower than would be required for pressureless sintering.

Defining Component Geometry

The die serves as the physical boundary that defines the final shape of the sintered sample, such as a cylinder or plate. Because the die must maintain its dimensions under load, its high-strength properties are vital to ensure the final ceramic meets precise geometric tolerances.

Thermal and Chemical Functions

Structural Integrity at Extreme Temperatures

Sintering SiC requires temperatures in the vicinity of 1850°C. Standard metal molds would melt or lose structural integrity in this environment.

High-strength graphite maintains its mechanical strength and dimensional stability at these temperatures, preventing deformation of the tool or the part during the thermal cycle.

Creating a Protective Reducing Atmosphere

Perhaps the most overlooked role of the graphite die is its chemical contribution. At high temperatures, the graphite material generates a reducing atmosphere within the mold assembly.

This local atmosphere inhibits the oxidation of both the SiC powder and any metallic sintering aids. By preventing the formation of silica impurity layers on particle surfaces, the die ensures the purity and performance of the final ceramic composite.

Understanding the Trade-offs

The Consumable Nature of the Die

Despite its strength, the graphite die is fundamentally a consumable component. The combination of immense pressure, extreme heat, and friction eventually degrades the mold, requiring replacement to maintain part tolerance.

Risk of Carbon Diffusion

While the graphite provides a protective atmosphere, it also acts as a carbon source. At elevated temperatures, there is a risk of carbon ions diffusing through grain boundaries into the ceramic material.

If not controlled, this can form impurity bands that alter the material's properties. Process control must manage grain growth to suppress this diffusion effect.

Making the Right Choice for Your Goal

When selecting graphite tooling for SiC sintering, align your choice with your specific processing targets:

- If your primary focus is densification: Prioritize graphite grades with high compressive strength to withstand pressures exceeding 30 MPa without creep or fracture.

- If your primary focus is material purity: Monitor the interaction between the die and the powder, and optimize thermal cycles to minimize the diffusion of carbon impurities into the ceramic matrix.

The graphite die is the linchpin of vacuum hot pressing, bridging the gap between raw powder and a fully densified, oxidation-free high-performance ceramic.

Summary Table:

| Feature | Role in SiC Sintering |

|---|---|

| Pressure Transmission | Delivers up to 30 MPa for particle rearrangement and plastic deformation |

| Thermal Stability | Maintains structural integrity at extreme temperatures around 1850°C |

| Chemical Environment | Creates a localized reducing atmosphere to prevent oxidation and silica formation |

| Geometry Control | Defines the final shape and ensures strict dimensional tolerances for the ceramic |

| Material Challenge | Acts as a consumable part that requires monitoring for carbon ion diffusion |

Maximize Your Material Performance with KINTEK

High-performance SiC ceramics require precision-engineered environments. Backed by expert R&D and manufacturing, KINTEK offers high-quality Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside advanced vacuum hot press solutions designed for extreme temperatures. Whether you need a standard setup or a system customizable for your unique lab needs, our expertise ensures your densification and purity goals are met.

Ready to elevate your lab's sintering capabilities? Contact us today for a professional consultation!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the advantages of using hot pressing in manufacturing? Achieve Superior Quality and Precision

- How does the uniaxial pressure applied by a vacuum hot press furnace affect the microstructure of ZrC-SiC materials?

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- What role does a vacuum hot press play in the consolidation of metallic glass powders? Expert Consolidation Insights

- What mold material is used for vacuum hot press sintering of aluminum matrix composites? Expert Choice Revealed

- How are vacuum hot pressing sintering furnaces classified based on temperature? Explore Low, Medium, and High-Tier Solutions

- How does a vacuum press machine work in shaping metals? Achieve Precision Metal Forming with Uniform Pressure

- What are the advantages of using a HIP sintering system over conventional sintering for Bismuth Telluride composites?