High-strength graphite is the definitive mold material used for the vacuum hot press sintering of aluminum matrix composites. It is uniquely qualified to withstand the rigorous duality of this process: enduring significant mechanical pressure to shape the composite while maintaining structural integrity at elevated temperatures.

Core Insight: Graphite molds are essential because they combine exceptional thermal conductivity with the mechanical strength required to define sample geometry under heavy loads. Their inherent chemical stability and self-lubricating properties further ensure uniform heating and efficient demolding without compromising the composite's integrity.

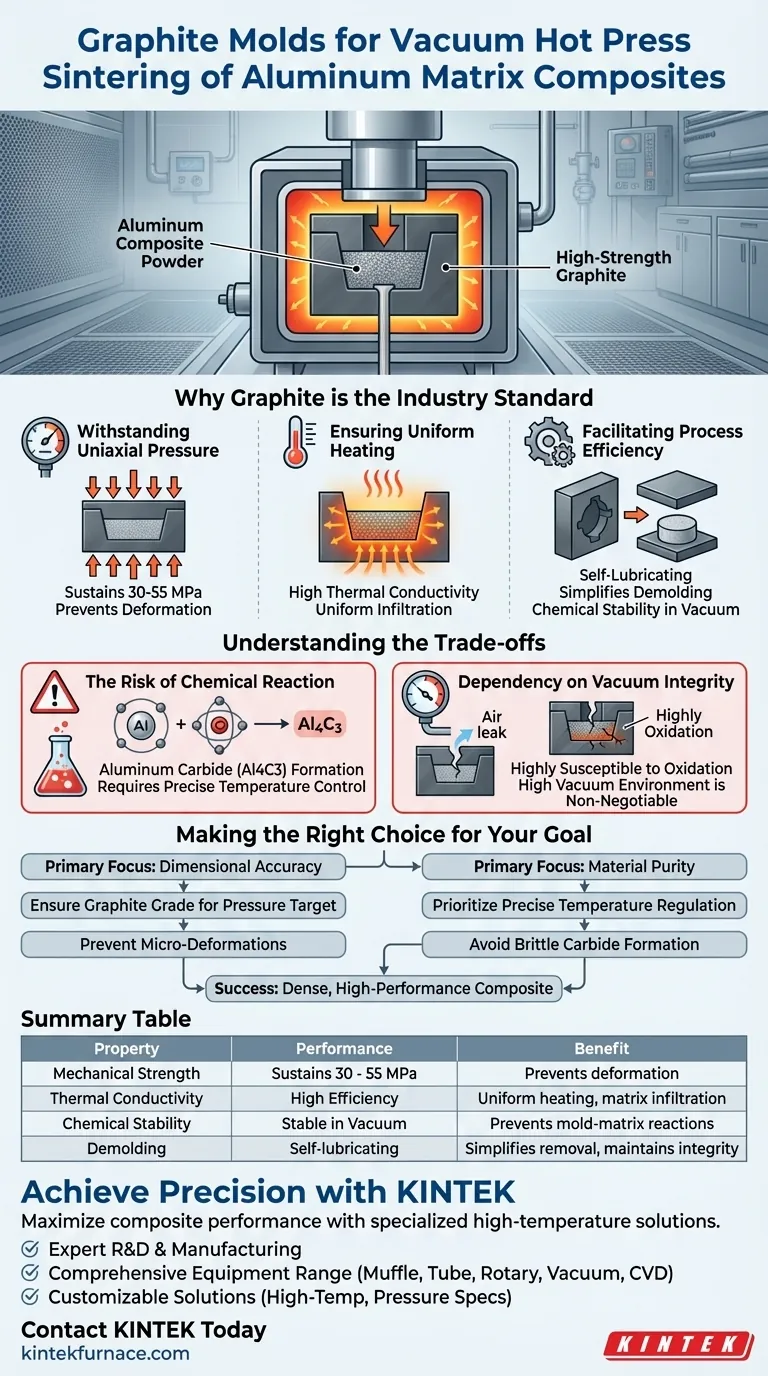

Why Graphite is the Industry Standard

Withstanding Uniaxial Pressure

The primary function of the mold is to act as a rigid forming container that restricts the lateral flow of the powder mixture. High-strength graphite is capable of sustaining uniaxial mechanical pressures—often ranging from 30 to 55 MPa—without deforming. This resistance forces the powder particles to rearrange and densify, creating a solid component with precise dimensions.

Ensuring Uniform Heating

Graphite possesses excellent thermal conductivity, which is critical for the consistency of the sintered part. This property ensures heat is transferred evenly from the furnace elements to the powder interior. Uniform heating promotes the consistent softening of the aluminum matrix, allowing it to infiltrate gaps between reinforcement fibers or particles effectively.

Facilitating Process Efficiency

Graphite offers natural self-lubricating properties, which significantly simplifies the removal of the sample (demolding) after the process is complete. Furthermore, graphite maintains chemical stability within a vacuum environment. This stability prevents severe reactions between the mold and the metal matrix, preserving the surface integrity of the final composite.

Understanding the Trade-offs

The Risk of Chemical Reaction

While graphite is generally stable, precise temperature control is vital when working with aluminum. If temperatures rise too high, the aluminum can react with the carbon in the mold to form aluminum carbide (Al4C3). This is a brittle compound that can degrade the mechanical properties and thermal conductivity of the final material.

Dependency on Vacuum Integrity

Graphite molds are highly susceptible to oxidation at sintering temperatures if exposed to air. Therefore, maintaining a high vacuum environment is non-negotiable. This protects the graphite mold from degradation and simultaneously prevents the oxidation of the aluminum powder, ensuring metallic bonding between particles.

Making the Right Choice for Your Goal

To maximize the effectiveness of high-strength graphite molds in your specific application:

- If your primary focus is Dimensional Accuracy: Ensure your graphite grade is rated to withstand pressures exceeding your target (e.g., 35-55 MPa) to prevent even micro-deformations during the densification phase.

- If your primary focus is Material Purity: Prioritize precise temperature regulation to leverage the mold's thermal conductivity while staying below the threshold where brittle aluminum carbide forms.

Success in vacuum hot pressing lies in balancing the mold's mechanical capacity with strict environmental controls to produce a dense, high-performance composite.

Summary Table:

| Property | Graphite Mold Performance | Benefit for Aluminum Sintering |

|---|---|---|

| Mechanical Strength | Sustains 30 - 55 MPa | Prevents deformation under uniaxial pressure |

| Thermal Conductivity | High Efficiency | Ensures uniform heating and matrix infiltration |

| Chemical Stability | Stable in Vacuum | Prevents mold-matrix reactions and surface damage |

| Demolding | Self-lubricating | Simplifies removal and maintains part integrity |

Achieve Precision in Advanced Material Sintering

Maximize your composite performance with specialized high-temperature solutions from KINTEK. Whether you are working with aluminum matrix composites or advanced ceramics, our expertise in vacuum hot press environments ensures you get the density and purity your research demands.

Why partner with KINTEK?

- Expert R&D & Manufacturing: Precision-engineered systems tailored for demanding thermal processes.

- Comprehensive Equipment Range: We offer Muffle, Tube, Rotary, Vacuum, and CVD systems.

- Customizable Solutions: High-temp lab furnaces designed to meet your unique pressure and temperature specifications.

Contact KINTEK Today to optimize your laboratory workflow and customize a furnace system built for your success.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of applying axial pressure during hot press sintering? Achieve High-Density Metal Composites

- Why is secondary processing using a hydraulic press and a sintering furnace necessary for aluminum matrix composites?

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are the main components of a vacuum hot press furnace? Unlock Precision Material Processing

- What types of heating elements are used in vacuum hot press furnaces? Optimize for High-Temp Performance

- What role does a laboratory hydraulic press play in forming BCZT powder? Achieve Precise 10mm Green Compacts

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance

- What is a vacuum hot press? Achieve Ultimate Material Purity and Density