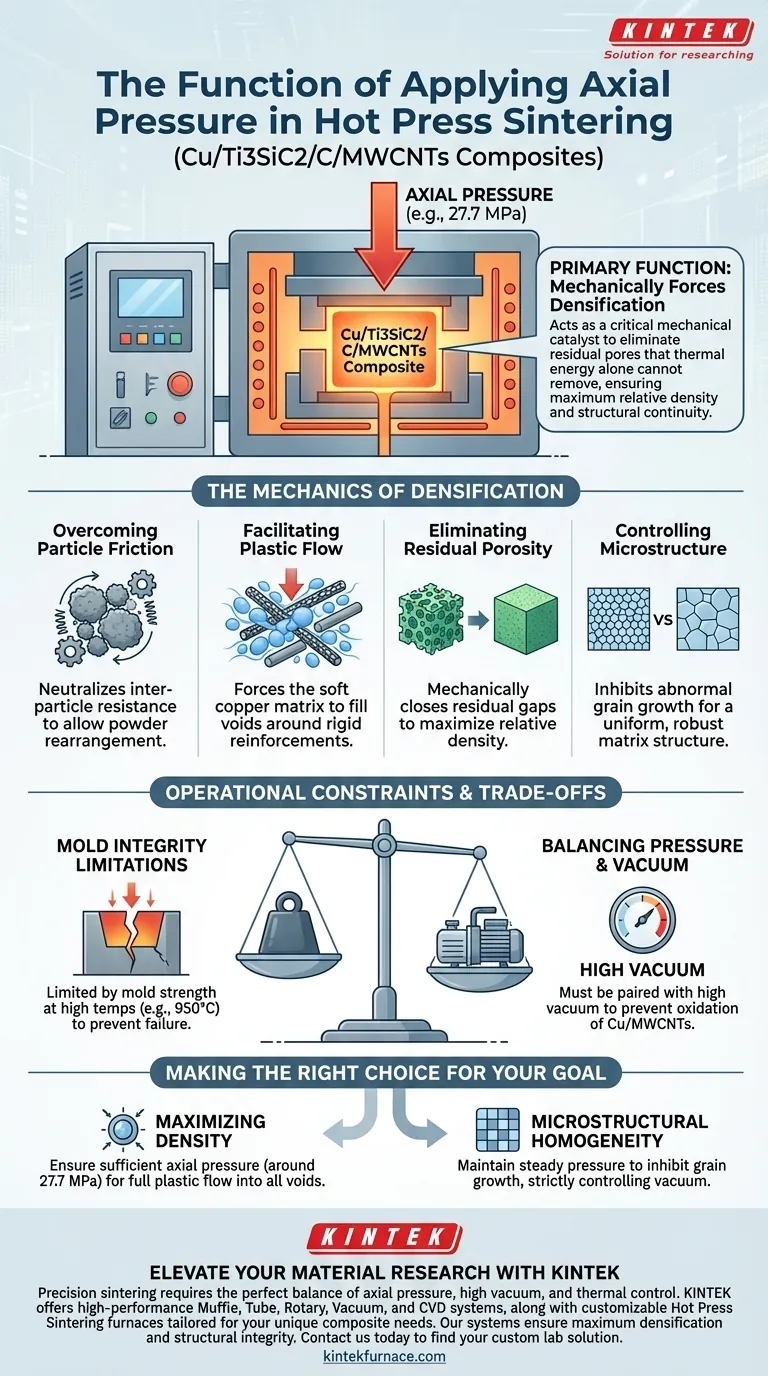

The primary function of applying axial pressure during hot press sintering is to mechanically force the densification of the composite material. By applying a specific load (e.g., 27.7 MPa) through a hydraulic system, the process overcomes inter-particle friction and drives the plastic flow of the copper matrix to fill voids around the rigid Ti3SiC2 and MWCNT skeletons.

Axial pressure acts as a critical mechanical catalyst, forcing the plastic deformation of the metal matrix to eliminate residual pores that thermal energy alone cannot remove. This ensures the composite achieves maximum relative density and structural continuity.

The Mechanics of Densification

Overcoming Particle Friction

In a powder mixture, individual particles naturally resist movement due to friction. Axial pressure is applied specifically to overcome this frictional resistance between the powder particles.

Without this external force, the particles would remain statically packed, preventing the rearrangement necessary for a dense final product.

Facilitating Plastic Flow

The composite consists of a soft matrix (Copper) and rigid reinforcements (Ti3SiC2 and MWCNTs). Pressure forces the plastic flow of the copper particles.

This deformation allows the copper to physically move and fill the interstitial spaces surrounding the harder, rigid skeletons of the reinforcement phases.

Eliminating Residual Porosity

During the sintering process, "necks" form between particles, but voids often remain. Physical pressure is essential for eliminating these residual pores.

By mechanically closing these gaps, the process maximizes the relative density of the material, which is the primary indicator of the composite's structural integrity.

Controlling Microstructure

Beyond simple densification, the application of pressure helps dictate the final grain structure. It aids in inhibiting abnormal grain growth, ensuring a more uniform and robust matrix.

Operational Constraints and Trade-offs

Mold Integrity Limitations

While higher pressure generally yields higher density, it is limited by the mechanical strength of the mold at high temperatures.

The mold acts as both the container and the pressure transmitter; exceeding its limits during the high-heat phase (e.g., 950°C) can lead to mold failure or deformation, compromising the sample.

Balancing Pressure and Vacuum

Pressure must be applied in concert with a high-vacuum environment.

If pressure is applied without maintaining a vacuum, trapped oxygen can oxidize the copper matrix or degrade the MWCNTs, rendering the densification efforts useless due to brittle inclusions.

Making the Right Choice for Your Goal

To optimize the sintering of Cu/Ti3SiC2/C/MWCNTs composites, consider the following regarding axial pressure:

- If your primary focus is Maximizing Density: Ensure the axial pressure is sufficient (around 27.7 MPa) to force the plastic flow of copper into all interstitial voids.

- If your primary focus is Microstructural Homogeneity: Maintain steady pressure to inhibit abnormal grain growth while strictly controlling the vacuum to prevent oxidation.

Effective axial pressure bridges the gap between a porous aggregate and a fully dense, high-performance composite.

Summary Table:

| Mechanism | Function in Sintering Process |

|---|---|

| Overcoming Friction | Neutralizes inter-particle resistance to allow powder rearrangement. |

| Plastic Flow | Forces the soft copper matrix to fill voids around rigid reinforcements. |

| Pore Elimination | Mechanically closes residual gaps to maximize relative density. |

| Microstructure Control | Inhibits abnormal grain growth for a uniform, robust matrix structure. |

Elevate Your Material Research with KINTEK

Precision sintering requires the perfect balance of axial pressure, high vacuum, and thermal control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable Hot Press Sintering furnaces tailored for your unique composite needs.

Whether you are working with metal-matrix composites like Cu/Ti3SiC2 or advanced MWCNT structures, our systems ensure maximum densification and structural integrity. Contact us today to find your custom lab solution and leverage our technical expertise for your next breakthrough.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the significance of dimensional accuracy in hot pressing? Achieve Net-Shape Manufacturing for Cost Savings

- What is the role of the vacuum environment in SiC/ZTA sintering? Enhance Densification & Material Purity

- Why is high-precision temperature control critical in SiC/Al sintering? Prevent Brittle Phases and Enhance Strength

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- How does a Spark Plasma Sintering (SPS) system compare to traditional furnaces for Al2O3-TiC ceramics?

- What role does uniaxial pressure play in a carbon tube vacuum hot press furnace? Achieve Ceramic Transparency

- What is hot pressing and what does it involve? Unlock Superior Material Density and Strength

- How does a vacuum hot press furnace contribute to the fabrication of ZnS infrared ceramics? Optimize Optical Quality