Uniaxial pressure functions as a critical mechanical catalyst that accelerates the sintering process beyond what thermal energy alone can achieve. In a carbon tube vacuum hot press furnace, this pressure physically forces ceramic particles together, effectively lowering the required temperature for densification and enabling the removal of microscopic voids that would otherwise destroy optical transparency.

Core Takeaway The application of uniaxial pressure solves the fundamental conflict in ceramic processing: achieving near-theoretical density without using excessive heat. By mechanically driving densification, you can eliminate light-scattering pores while maintaining a fine grain structure, a balance that is virtually impossible to achieve with pressureless sintering alone.

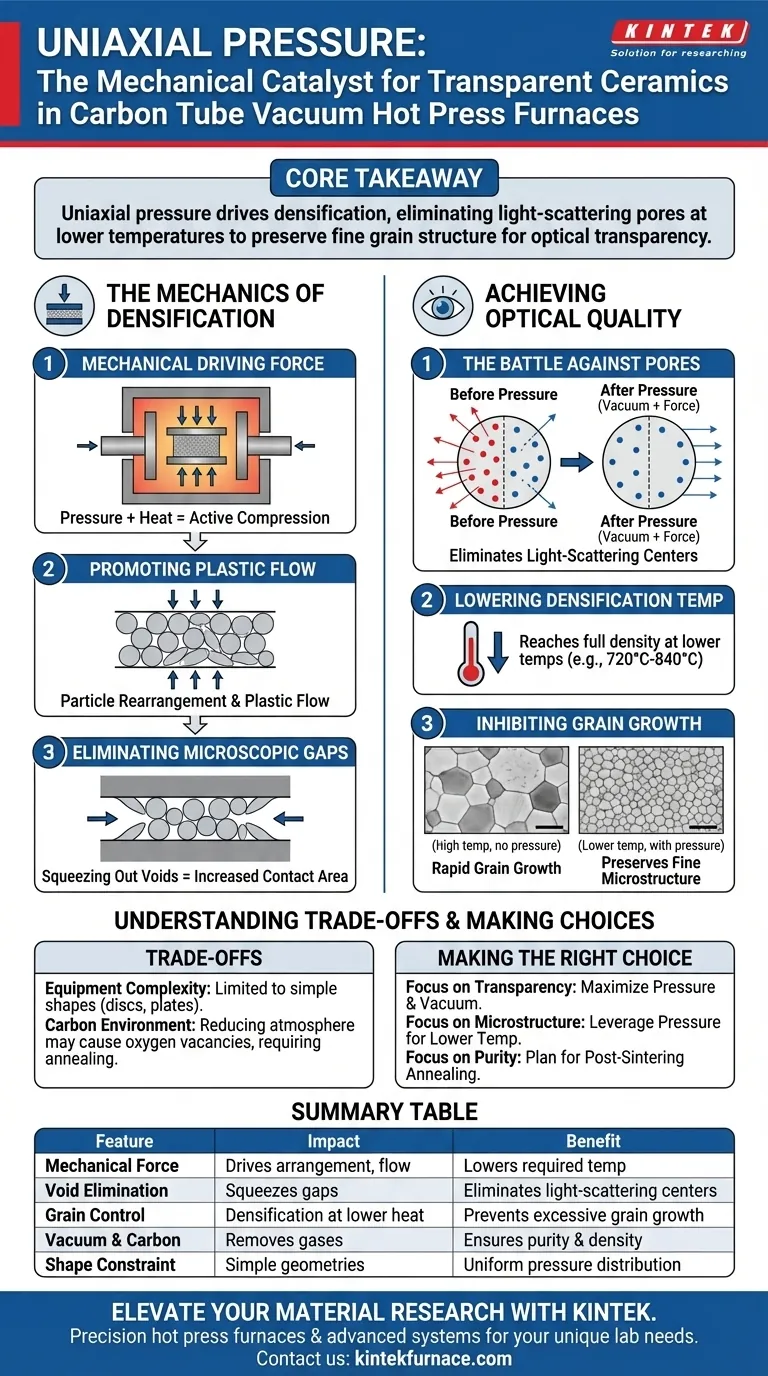

The Mechanics of Densification

The Mechanical Driving Force

In standard sintering, heat acts as the primary energy source to fuse particles. In a vacuum hot press furnace, uniaxial pressure provides an additional mechanical driving force. This force supplements the thermal energy, actively compressing the material rather than relying solely on atomic diffusion.

Promoting Plastic Flow

The applied pressure induces plastic flow and particle rearrangement within the ceramic powder. This means individual particles are physically shifted and deformed to fit closer together, effectively interlocking the microstructure.

Eliminating Microscopic Gaps

By forcing this microscopic deformation, the pressure effectively squeezes out internal voids. This significantly increases the effective contact area, allowing for faster and more complete bonding between particles.

Achieving Optical Quality

The Battle Against Pores

For a ceramic to be transparent, it must be virtually free of porosity; even tiny pores act as light-scattering centers, rendering the material opaque. The combination of high vacuum (to remove interstitial gases) and mechanical pressure (to close voids) is the core method for eliminating these residual pores.

Lowering the Densification Temperature

Perhaps the most significant role of pressure is that it lowers the temperature required to reach full density. Because mechanical force is doing part of the work, the ceramic creates a dense "green body" at temperatures significantly lower (e.g., 720°C-840°C for certain materials) than those required in pressureless sintering.

Inhibiting Grain Growth

There is a direct link between temperature and grain size: higher temperatures usually lead to rapid, uncontrolled grain growth. By allowing for sintering at lower temperatures, uniaxial pressure inhibits excessive grain growth. This preserves the fine microstructure necessary for superior mechanical strength and optical clarity.

Understanding the Trade-offs

Equipment Complexity and Throughput

While effective, introducing uniaxial pressure limits the geometry of the parts you can produce. Unlike pressureless sintering, which can handle complex shapes, hot pressing is generally restricted to simple shapes like discs or plates due to the constraints of the mold and the direction of the force.

The Carbon Environment

The "Carbon Tube" aspect of the furnace introduces a reducing atmosphere. While the pressure achieves density, the vacuum and carbon environment can strip oxygen from the lattice, creating oxygen vacancies or color centers.

- Note: This often necessitates a post-processing step (annealing in an air atmosphere) to re-oxidize the material and restore full transparency.

Making the Right Choice for Your Goal

To maximize the effectiveness of your sintering process, consider your specific endpoints:

- If your primary focus is Optical Transparency: Prioritize high pressure and vacuum levels to eliminate all residual pores and light-scattering centers.

- If your primary focus is Microstructural Control: Leverage the pressure to reduce maximum sintering temperatures, ensuring grains remain small and uniform.

- If your primary focus is Material Purity: Be prepared to anneal your samples post-sintering to correct oxygen deficiencies caused by the vacuum-carbon environment.

Uniaxial pressure is not just a compaction tool; it is the lever that allows you to decouple density from temperature, granting you precise control over the optical properties of your final ceramic.

Summary Table:

| Feature | Impact on Transparent Ceramics | Benefit |

|---|---|---|

| Mechanical Force | Drives particle rearrangement and plastic flow | Lowers required sintering temperature |

| Void Elimination | Squeezes out microscopic internal gaps | Eliminates light-scattering centers |

| Grain Control | Enables densification at lower heat | Prevents excessive grain growth |

| Vacuum & Carbon | Removes interstitial gases/reduces atmosphere | Ensures material purity and density |

| Shape Constraint | Restricted to discs/plates/simple geometries | Uniform pressure distribution |

Elevate Your Material Research with KINTEK

Precision in pressure and temperature is the key to mastering optical transparency. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, including advanced hot press furnaces fully customizable for your unique laboratory needs.

Whether you are aiming for near-theoretical density or precise microstructural control, our engineering team provides the specialized tools to help you succeed. Contact us today to find the perfect high-temp solution for your lab!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why is vacuum press technology indispensable in modern metalworking? Unlock Precision and Quality in Metal Forming

- How does industrial-scale FAST equipment address production challenges? Scale-up Your Sintering Capabilities

- Why are high-strength graphite molds preferred for the vacuum hot pressing sintering of Al-Si/graphite composites?

- What is the primary function of a vacuum hot press furnace in the preparation of Fe-based amorphous alloy/aluminum microlaminated composites? Achieve Perfect Solid-State Bonding

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What Role Does a Graphite Mold Play in Vacuum Hot Pressing? Enhancing Composite Sintering Efficiency

- How does the high vacuum environment affect Ti-Al bonding? Unlock High-Strength Metallurgical Bonding