In vacuum hot pressing, temperature, pressure, and vacuum work in concert to consolidate powders into a dense, high-performance solid. Temperature provides the energy for atoms to move and bond, pressure forces particles into intimate contact to eliminate voids, and the vacuum environment protects the material from chemical reactions that would compromise its integrity.

The core principle of vacuum hot pressing is not just the application of heat and force, but the precise control of these variables in a protected environment to overcome the barriers to densification while preventing microstructural damage like oxidation or excessive grain growth.

The Synergistic Roles of Temperature, Pressure, and Vacuum

To master this process, you must understand how each parameter functions not in isolation, but as part of a synergistic system. The goal is to consolidate a powder into a fully dense part with a controlled microstructure.

Temperature: The Engine of Atomic Motion

The primary role of temperature is to increase the kinetic energy of the atoms within the powder particles.

This elevated energy activates atomic diffusion, the primary mechanism for material transport. Atoms migrate across particle boundaries, filling the gaps (or pores) between them and forming strong metallic or covalent bonds.

Temperature also makes the material more ductile. This softening allows for plastic deformation, where particles change shape to pack together more efficiently under the applied pressure.

Pressure: The Force for Densification

Pressure is the external force that drives the consolidation process. Its first job is to promote particle rearrangement, breaking down loose bridges and allowing the powder to pack into a denser configuration.

As particles are forced together, the pressure creates high-stress contact points. This localized stress significantly enhances the rate of diffusion and plastic flow, accelerating the elimination of porosity.

Ultimately, applied pressure ensures that the gaps between particles are mechanically closed, a critical step that diffusion alone cannot accomplish efficiently.

Vacuum: The Shield for Material Purity

The vacuum environment is essential for material integrity, especially for reactive materials like non-oxide ceramics or certain metals.

Its primary function is to prevent oxidation. At high temperatures, oxygen and other atmospheric gases would readily react with particle surfaces, forming brittle oxide layers that act as diffusion barriers and prevent strong bonding.

Additionally, the vacuum helps remove adsorbed gases from the particle surfaces and any trapped gas within the pores. This outgassing is crucial for achieving the highest possible density and preventing internal defects in the final component.

How These Factors Shape the Final Microstructure

The interplay of temperature, pressure, and vacuum directly dictates the final microstructure, which in turn determines the material's properties—its strength, hardness, and thermal or electrical performance.

Achieving Full Density

The combined effect of heat and pressure is to systematically eliminate porosity. The result is a component that approaches 100% of its theoretical density, maximizing mechanical strength and other physical properties.

Controlling Grain Growth

Grain size is a critical microstructural feature. While high temperature is necessary for diffusion, it also promotes grain growth, where smaller grains are consumed by larger ones.

Excessive grain growth can often be detrimental to mechanical properties like hardness and toughness. A key challenge is to find a temperature-pressure combination that enables full densification without causing undesirable coarsening of the microstructure.

Ensuring Purity and Uniformity

By preventing unwanted chemical reactions, the vacuum ensures phase purity. This results in a uniform microstructure free from weak, brittle secondary phases, leading to predictable and reliable material performance.

Understanding the Trade-offs

Optimizing vacuum hot pressing requires balancing competing factors. There is no single "best" setting; the ideal parameters depend on the material and the desired outcome.

Temperature vs. Grain Size

Higher temperatures accelerate densification but also accelerate grain growth. You must select a temperature high enough to activate diffusion but low enough to maintain a fine-grained structure if high strength or hardness is the goal.

Pressure vs. Component Integrity

Increasing pressure can help lower the required densification temperature, thereby limiting grain growth. However, excessive pressure can damage delicate components, cause die failure, or introduce internal stress into the part.

Vacuum Level vs. Process Cost

A "harder" (higher) vacuum provides better protection against oxidation but requires more powerful pumps and longer processing times, increasing operational costs. The required vacuum level must be balanced against the material's reactivity and the project budget.

Making the Right Choice for Your Goal

The optimal process parameters are a direct function of your end goal. Tailor your approach based on the most critical property for your application.

- If your primary focus is achieving maximum density: Utilize the highest practical temperature your material can withstand without unacceptable grain growth, coupled with sufficient pressure to close all porosity.

- If your primary focus is a fine-grained microstructure for high strength: Use the lowest possible temperature that allows for full densification, often compensating by using higher pressure.

- If your primary focus is processing highly reactive materials: Prioritize a high-quality vacuum environment to prevent the formation of brittle oxide layers that inhibit bonding.

Mastering vacuum hot pressing is a matter of understanding and controlling the interplay between these three critical variables to achieve your desired material structure and properties.

Summary Table:

| Parameter | Role in Vacuum Hot Pressing | Effect on Microstructure |

|---|---|---|

| Temperature | Increases atomic diffusion and plasticity for bonding | Controls grain growth and densification |

| Pressure | Forces particle contact and eliminates voids | Reduces porosity and enhances density |

| Vacuum | Prevents oxidation and removes gases | Ensures purity and uniform phase structure |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs for superior material bonding and microstructure control. Contact us today to discuss how we can enhance your research and production processes!

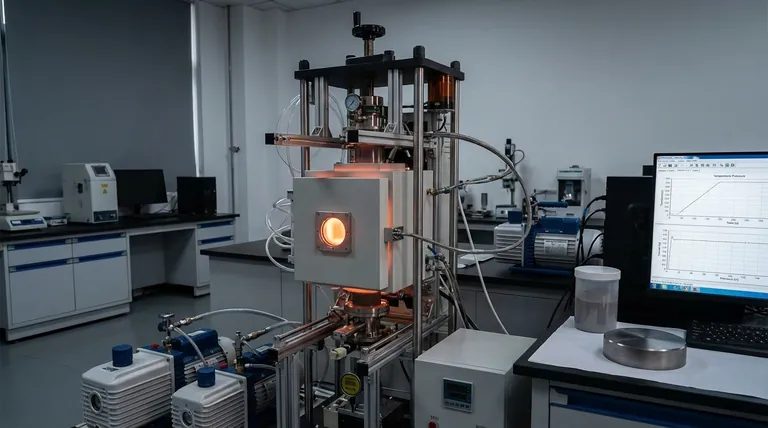

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance

- How do hot press furnaces contribute to graphene synthesis? Unlock High-Quality Material Production

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials