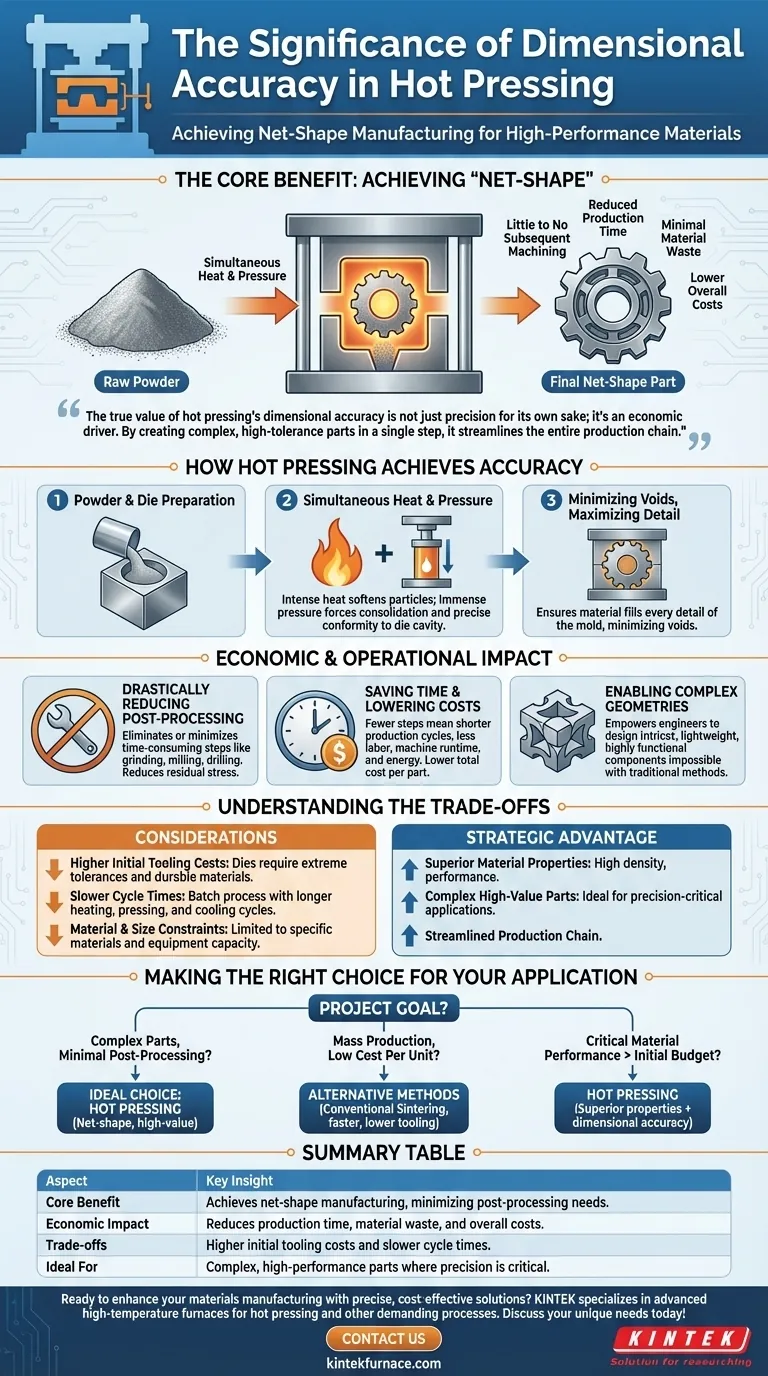

In advanced materials manufacturing, the significance of dimensional accuracy in hot pressing is its ability to produce components that are at or near their final, intended shape directly from the press. This "net-shape" capability means parts require little to no subsequent machining or finishing, drastically reducing production time, material waste, and overall manufacturing costs.

The true value of hot pressing's dimensional accuracy is not just precision for its own sake; it's an economic driver. By creating complex, high-tolerance parts in a single step, it streamlines the entire production chain for high-performance materials.

The Core Benefit: Achieving 'Net-Shape' Manufacturing

Hot pressing is a powder metallurgy process where powder is simultaneously heated and placed under uniaxial pressure within a die. This unique combination is what enables its signature accuracy.

What is Dimensional Accuracy?

Dimensional accuracy refers to how closely the final dimensions of a manufactured component match the original specifications of its design blueprint. Tight tolerances mean there is very little acceptable deviation between the design and the finished part.

How Hot Pressing Achieves This

During the process, the intense heat softens the material particles, while the immense pressure forces them to consolidate and conform precisely to the shape of the die cavity. This simultaneous action minimizes voids and ensures the material fills every detail of the mold.

From Raw Material to Finished Part

Unlike processes that first create a rough shape (a "billet") and then machine it down, hot pressing consolidates the raw powder and forms the final geometry in a single, controlled operation. This integration is the key to its efficiency.

The Economic and Operational Impact

The ability to create net-shape parts has profound effects on the viability and cost-effectiveness of a manufacturing project.

Drastically Reducing Post-Processing

Secondary machining operations like grinding, milling, or drilling are often time-consuming, costly, and can introduce residual stress into a component. By producing a dimensionally accurate part from the start, hot pressing minimizes or entirely eliminates the need for these finishing steps.

Saving Time and Lowering Costs

Fewer manufacturing steps directly translate to a shorter production cycle. This saves on labor, machine runtime, and energy consumption, leading to a lower total cost per part, especially for materials that are difficult to machine.

Enabling Complex Geometries

High dimensional accuracy empowers engineers to design intricate components that would be challenging, expensive, or even impossible to create through traditional subtractive manufacturing. This opens the door for optimized, lightweight, and highly functional designs.

Understanding the Trade-offs

While powerful, the precision of hot pressing comes with specific considerations. It is not the optimal solution for every application.

Higher Initial Tooling Costs

The dies used in hot pressing must be machined to extremely high tolerances and made from materials capable of withstanding intense heat and pressure. This results in a higher upfront investment in tooling compared to other methods.

Slower Cycle Times

Hot pressing is typically a batch process with longer heating, pressing, and cooling cycles. Compared to high-volume methods like metal injection molding or conventional pressing and sintering, its per-part cycle time is slower.

Material and Size Constraints

The process is best suited for specific materials, primarily advanced ceramics, composites, and certain metal powders. Furthermore, the size of the final component is limited by the capacity and size of the hot pressing equipment.

Making the Right Choice for Your Application

Selecting the right manufacturing process depends entirely on your project's specific goals regarding complexity, volume, and cost.

- If your primary focus is producing complex, high-performance parts with minimal post-processing: Hot pressing is an ideal choice, as its net-shape capability delivers high-value components efficiently.

- If your primary focus is mass production of simple parts at the lowest per-unit cost: Alternative methods like conventional sintering may be more economical due to their faster cycle times and lower tooling costs.

- If your primary focus is developing a final product where material performance is more critical than initial tooling budget: Hot pressing offers superior material properties (like high density) in addition to its dimensional accuracy, justifying the investment.

Ultimately, understanding the role of dimensional accuracy allows you to leverage hot pressing as a strategic tool for creating superior components where precision and performance are paramount.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Core Benefit | Achieves net-shape manufacturing, minimizing post-processing needs. |

| Economic Impact | Reduces production time, material waste, and overall costs. |

| Trade-offs | Higher initial tooling costs and slower cycle times. |

| Ideal For | Complex, high-performance parts where precision is critical. |

Ready to enhance your materials manufacturing with precise, cost-effective solutions? KINTEK specializes in advanced high-temperature furnaces, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, tailored for hot pressing and other demanding processes. Our deep customization capabilities ensure we meet your unique experimental and production needs, helping you achieve superior dimensional accuracy and efficiency. Contact us today to discuss how we can support your project and drive your success!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%