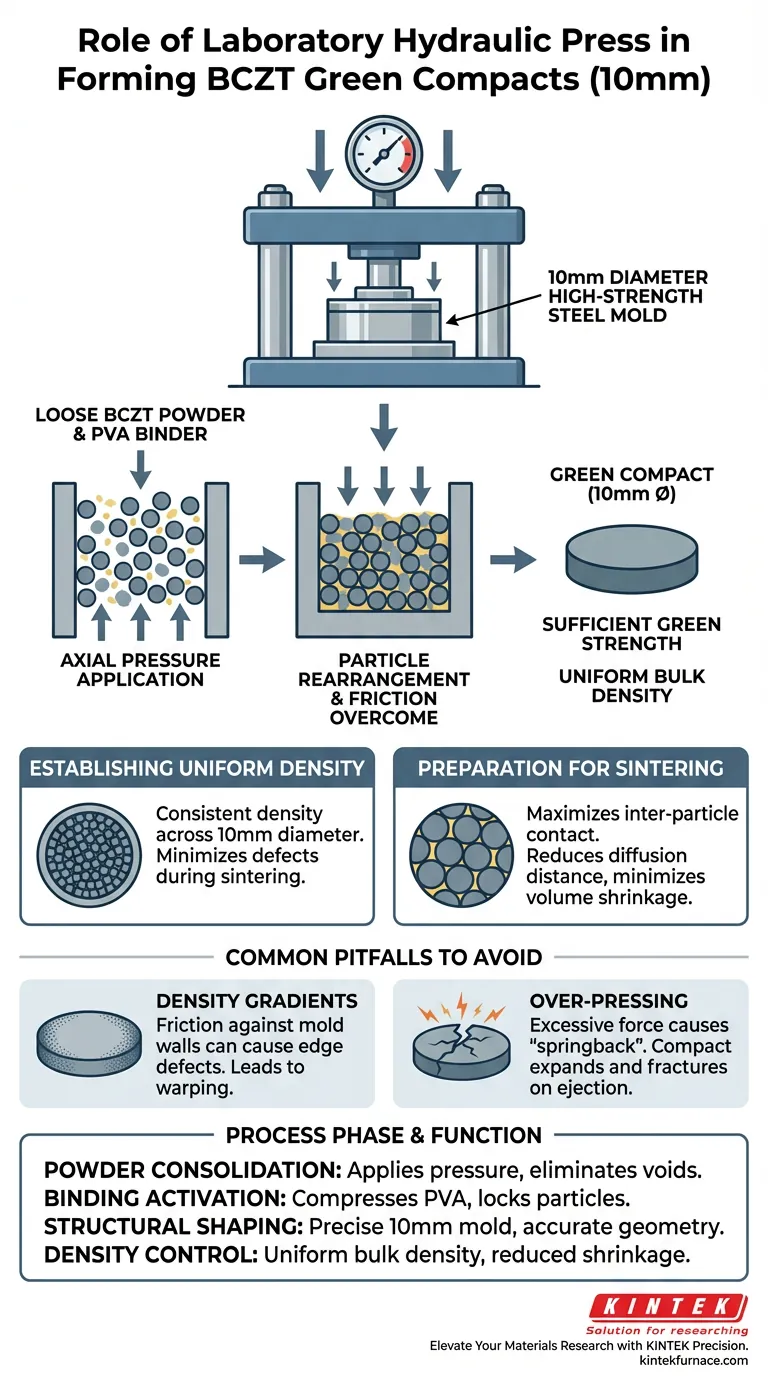

The laboratory hydraulic press acts as the primary mechanism for densification and shaping. It applies precise, uniform axial pressure through high-strength steel molds to transform loose Ba0.85Ca0.15Zr0.1Ti0.9O3 (BCZT) powder into a solid, 10mm diameter disc. This process creates a "green compact" with sufficient mechanical strength to be handled before the final firing stage.

The press allows powder particles to overcome friction and rearrange effectively, utilizing a binder to establish a consistent bulk density that is essential for successful high-temperature sintering.

The Mechanics of BCZT Consolidation

Overcoming Particle Friction

Loose BCZT powder naturally resists packing due to friction between particles. The hydraulic press applies the necessary force to overcome this resistance.

By exerting high axial pressure, the press forces the particles to slide past one another. This rearrangement eliminates voids and ensures tight packing within the 10mm mold.

The Role of Binders

To facilitate this movement, a binder such as Polyvinyl Alcohol (PVA) is often mixed with the powder.

The pressure from the press activates the binding properties of the PVA. This helps lock the rearranged particles into place, ensuring the shape is retained after the pressure is released.

Achieving "Green Strength"

The immediate goal of using the press is to create a "green compact"—an unfired ceramic body.

This compact must possess sufficient physical strength to withstand ejection from the steel mold and subsequent handling. Without the uniform pressure provided by the hydraulic system, the 10mm disc would likely crumble or crack upon removal.

Critical Impact on Final Properties

Establishing Uniform Density

The hydraulic press does more than just shape the powder; it establishes the bulk density of the material.

Uniform application of pressure ensures that the density is consistent throughout the entire 10mm diameter. This consistency is vital for avoiding defects during the subsequent manufacturing steps.

Preparation for Sintering

The quality of the green compact dictates the success of the sintering (firing) process.

By maximizing inter-particle contact through pressure, the press reduces the distance atoms must diffuse during heating. This minimizes volume shrinkage and creates a stable foundation for the material to densify into a functional ceramic.

Common Pitfalls to Avoid

Density Gradients

While hydraulic presses are effective, applying axial pressure can sometimes create density gradients.

Friction against the mold walls may cause the edges of the 10mm disc to be less dense than the center. This can lead to warping during sintering if the pressure is not applied smoothly or if the mold walls are not properly lubricated.

Over-Pressing

It is possible to apply too much pressure.

Excessive force can cause "springback," where trapped air or elastic energy in the binder causes the compact to expand and fracture when ejected. Finding the optimal pressure window is critical for BCZT integrity.

Making the Right Choice for Your Goal

To ensure high-quality BCZT samples, tailor your pressing strategy to your specific outcome:

- If your primary focus is mechanical handling: Ensure you are using sufficient pressure to activate the PVA binder, creating a robust green body that won't crumble.

- If your primary focus is final density: Prioritize uniform pressure application to maximize particle rearrangement, which minimizes shrinkage and cracking during the high-temperature sintering phase.

A precisely controlled hydraulic pressing stage is the non-negotiable prerequisite for producing high-performance BCZT ceramics.

Summary Table:

| Process Phase | Function of Hydraulic Press | Key Outcome |

|---|---|---|

| Powder Consolidation | Applies high axial pressure to overcome particle friction. | Elimination of voids and tight particle packing. |

| Binding Activation | Compresses PVA binder to lock particles in place. | High green strength for safe handling. |

| Structural Shaping | Forces material into a precise 10mm high-strength steel mold. | Accurate disc geometry and dimensions. |

| Density Control | Establishes uniform bulk density across the disc. | Reduced volume shrinkage during final sintering. |

Elevate Your Materials Research with KINTEK Precision

Achieving the perfect BCZT green compact requires more than just force—it requires precision and reliability. KINTEK provides industry-leading laboratory hydraulic presses and precision molds designed to eliminate density gradients and prevent sample fracturing.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as customizable high-temperature furnaces and hydraulic equipment tailored to your unique research needs.

Don't let "springback" or density gradients ruin your sintering results. Contact our technical specialists today to find the ideal pressing solution for your advanced ceramic materials.

Visual Guide

References

- Baoyun Wang, Yongjun Tian. High-temperature structural disorders stabilize hydrous aluminosilicates in the mantle transition zone. DOI: 10.1038/s41467-025-56312-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance

- How does a vacuum hot press furnace improve Ti2AlN ceramics? Achieve 4.15 g/cm³ Density and Superior Strength

- Why is a high vacuum essential for ZnS hot press sintering? Achieve Maximum Infrared Transmittance

- What is the benefit of programmable multi-segment process control in hot press sintering furnaces for nano-copper?

- What industrial applications utilize vacuum hot press furnaces? Essential for Aerospace, Medical, and Electronics

- What are the characteristics of ultrahigh pressure sintering for ceramics? Achieve Dense, Fine-Grained Ceramics

- What are the technical advantages of Spark Plasma Sintering (SPS) systems? Faster Densification and Superior Strength

- How does activated sintering work for ceramic materials? Lower Temperatures, Faster Densification