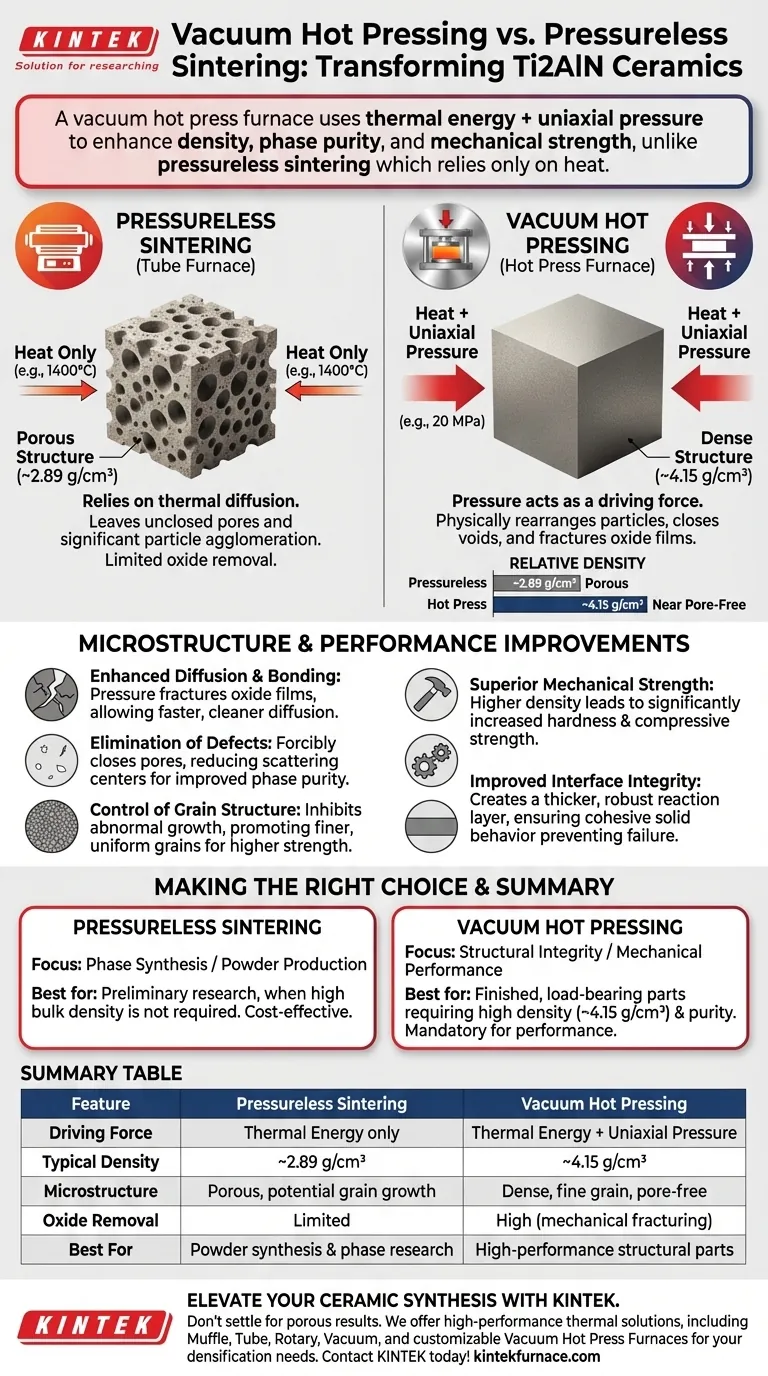

A vacuum hot press furnace fundamentally transforms the quality of Ti2AlN ceramics by applying uniaxial mechanical pressure in addition to high thermal energy. While conventional pressureless sintering often yields a porous material with a density of only ~2.89 g/cm³, the pressure-assisted mechanism of a hot press drives the density up to ~4.15 g/cm³, resulting in a nearly pore-free, mechanically superior component.

Core Takeaway Pressureless sintering relies solely on heat, often failing to eliminate pores in complex ceramics like Ti2AlN. Vacuum hot pressing introduces mechanical pressure as an additional "driving force," physically forcing particles to rearrange and bond. This closes voids and fractures surface oxides, delivering a material with optimized density, phase purity, and mechanical strength.

The Mechanics of Densification

Overcoming Kinetic Limitations

In pressureless sintering (using a standard tube furnace), the material relies on atomic diffusion driven only by temperature (e.g., 1400°C). This often leaves unclosed pores and results in significant particle agglomeration.

The Role of Mechanical Pressure

A vacuum hot press applies uniaxial pressure (e.g., 20 MPa) during the heating process. This provides an external driving force that works alongside thermal energy. It physically forces particles together, promoting rearrangement and ensuring voids are filled.

Quantifiable Density Gains

The difference in results is drastic. Ti2AlN samples synthesized without pressure achieve a relative density of roughly 2.891 g/cm³. Under the same thermal conditions but with pressure assistance, the density increases to approximately 4.15 g/cm³.

Microstructural Improvements

Enhanced Diffusion and Bonding

High density is not just about packing particles tighter; it is about bonding. The applied pressure helps fracture oxide films on the powder surfaces, which are common barriers in ceramic synthesis. Breaking these films allows for cleaner, faster diffusion between elements (Ti, Al, N) at the grain boundaries.

Elimination of Defects

By forcibly closing pores, the hot press significantly reduces internal defects. In similar ceramic systems, this reduction in scattering centers (voids and grain boundaries) has been shown to improve physical properties. For Ti2AlN, this manifests as substantially improved phase purity, ensuring the material consists of the desired crystal structure rather than secondary byproducts.

Control of Grain Structure

Pressure inhibits abnormal grain growth. In pressureless environments, grains can grow unevenly, weakening the material. The mechanical constraint of the hot press encourages a finer, more uniform grain structure, which is directly linked to higher material strength.

Impact on Performance

Superior Mechanical Strength

The elimination of porosity directly correlates to mechanical performance. A dense body with strong inter-granular bonding exhibits significantly higher hardness and compressive strength compared to a porous, pressureless-sintered counterpart.

Improved Interface Integrity

The pressure-assisted diffusion creates a thicker, more robust reaction layer between particles. This "transition zone" ensures that the material acts as a cohesive solid rather than a collection of loosely bonded particles, preventing failure under stress.

Understanding the Trade-offs

Equipment Complexity

A vacuum/atmosphere tube furnace is capable of inducing the necessary solid-phase reactions to create Ti2AlN. If the goal is simply preliminary synthesis or powder creation, the tube furnace is sufficient and likely more cost-effective.

The Necessity of Pressure

However, for structural applications, the tube furnace is insufficient. It cannot provide the densification required for a finished part. The hot press adds complexity and cost, but it is mandatory if the goal is a fully dense, load-bearing ceramic component.

Making the Right Choice for Your Goal

To select the correct sintering method for your specific Ti2AlN requirements, consider the following:

- If your primary focus is Phase Synthesis/Powder Production: Rely on pressureless sintering (tube furnace). It successfully generates the main crystalline phase and is suitable when high bulk density is not required.

- If your primary focus is Structural Integrity/Mechanical Performance: You must use a vacuum hot press. It is the only way to achieve the ~4.15 g/cm³ density required to maximize hardness, reduce porosity, and ensure phase purity.

Ultimately, while heat initiates the chemical reaction, it is the application of pressure that ensures the structural integrity required for high-performance applications.

Summary Table:

| Feature | Pressureless Sintering (Tube Furnace) | Vacuum Hot Pressing |

|---|---|---|

| Driving Force | Thermal Energy only | Thermal Energy + Uniaxial Pressure |

| Typical Density | ~2.89 g/cm³ | ~4.15 g/cm³ |

| Microstructure | Porous, potential grain growth | Dense, fine grain, pore-free |

| Oxide Removal | Limited | High (mechanical fracturing) |

| Best For | Powder synthesis & phase research | High-performance structural parts |

Elevate Your Ceramic Synthesis with KINTEK

Don't settle for porous results when your application demands structural perfection. KINTEK provides industry-leading thermal solutions designed to meet the rigorous demands of advanced materials research. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as customizable Vacuum Hot Press Furnaces tailored to your unique densification needs.

Whether you are performing preliminary phase synthesis or manufacturing load-bearing Ti2AlN components, our engineers are ready to help you optimize your process.

Contact KINTEK today to find the perfect furnace for your lab!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the technical advantages of Spark Plasma Sintering (SPS) systems? Faster Densification and Superior Strength

- What function does a vacuum hot press furnace serve in the densification of Nb-22.5Cr-5Si alloys? Achieve Full Density and Purity for Refractory Alloys

- Why are high-strength graphite molds preferred for the vacuum hot pressing sintering of Al-Si/graphite composites?

- What is the role of sacrificial inserts in the Spark Plasma Sintering (SPS) process? Master Complex Geometry Design

- What are the key benefits of using Vacuum Hot Press equipment in manufacturing? Achieve Superior Material Quality and Performance

- Why is hot pressing ideal for critical applications in industries like aerospace and automotive? Achieve Unmatched Component Density and Reliability

- What are the technical advantages of using Pulsed Current Sintering (PCS) for Ag2S1-xTex? Optimize Your Microstructure

- What are the advantages of a high-pressure vacuum induction hot press furnace? Boost SiGe Thermoelectric Performance