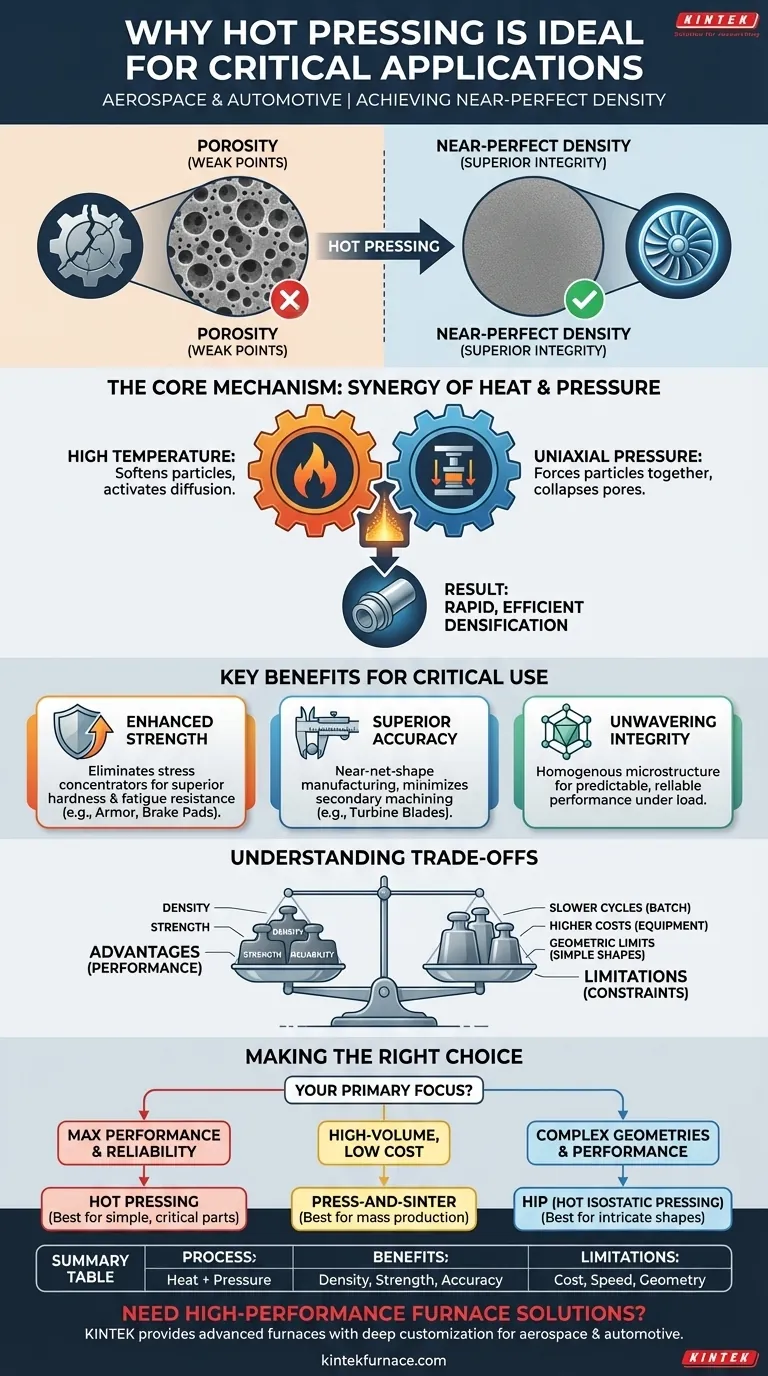

In essence, hot pressing is the ideal manufacturing process for critical applications because it simultaneously applies high temperature and intense pressure. This combination fundamentally eliminates the internal voids common in other powder metallurgy methods, resulting in a final component with near-perfect density, exceptional strength, and predictable performance under extreme stress.

While many processes can form a part, they often leave behind microscopic porosity that acts as a built-in failure point. Hot pressing directly addresses this by using heat and force to consolidate powdered materials to nearly their theoretical maximum density, creating components with unparalleled structural integrity required for industries like aerospace and automotive.

The Core Mechanism: How Hot Pressing Achieves Superior Density

Hot pressing is a materials consolidation process where powdered material is heated to a high temperature—typically below its melting point—while being compacted under uniaxial pressure within a die. The synergy between heat and pressure is what makes the process so effective.

The Role of High Temperature

Heating the material provides the thermal energy necessary to soften the individual powder particles. This increased malleability makes them much easier to deform and reshape.

Critically, the high temperature also activates diffusion mechanisms, allowing atoms to move across the boundaries of adjacent particles and form strong, cohesive metallurgical bonds.

The Role of Uniaxial Pressure

While the material is hot and pliable, a powerful press applies directional (uniaxial) force. This pressure physically forces the softened particles together, collapsing the pores and empty spaces between them.

The mechanical force ensures that densification occurs rapidly and efficiently throughout the entire component, squeezing out residual porosity.

Why Simultaneous Application is Key

Applying heat and pressure at the same time is the defining advantage of hot pressing. Heat allows the material to densify at much lower pressures than would be required for cold pressing.

Conversely, the pressure dramatically accelerates the densification process compared to conventional sintering (which uses heat alone), preventing undesirable grain growth that can compromise a material's mechanical properties.

Key Benefits for Critical Applications

The dense, homogenous microstructure achieved through hot pressing directly translates into the superior properties demanded by aerospace, automotive, defense, and medical applications.

Enhanced Mechanical Strength

Porosity is the enemy of strength. Voids act as stress concentrators, creating initiation sites for cracks. By eliminating these voids, hot pressing produces components with significantly higher hardness, toughness, and fatigue resistance.

This is why hot-pressed materials, such as ceramic composites or specialty alloys, are used for turbine blades, brake pads, and armor, where material failure would be catastrophic.

Superior Dimensional Accuracy

Because the material is consolidated within a rigid, precisely machined die, the final component conforms very closely to the desired shape. This is known as near-net-shape manufacturing.

This high degree of accuracy minimizes the need for extensive and costly secondary machining, which is especially important when working with very hard or difficult-to-machine materials like technical ceramics.

Unwavering Material Integrity

The hot pressing process results in a highly uniform and homogenous microstructure. There are no significant variations in density or composition across the part.

This consistency ensures that the material behaves predictably under load, a non-negotiable requirement for critical components where performance must be reliable and repeatable.

Understanding the Trade-offs and Limitations

Despite its advantages, hot pressing is not a universal solution. Its benefits come with practical and economic trade-offs that must be considered.

Slower Cycle Times

Hot pressing is a batch process, not a continuous one. The cycle of loading the die, heating the material, applying pressure, holding, and cooling is inherently time-consuming. This makes it unsuitable for high-volume, low-cost mass production.

Higher Process Costs

The required equipment—high-temperature furnaces, powerful hydraulic presses, and control systems—represents a significant capital investment. Furthermore, the process is energy-intensive, adding to the operational cost.

Geometric Constraints

The uniaxial nature of the pressure application works best for parts with relatively simple geometries, such as discs, blocks, or cylinders. Producing complex, three-dimensional shapes with undercuts or internal cavities is often impractical or impossible with standard hot pressing.

Die Material Challenges

The die itself must be made from a material that can withstand extreme temperatures and pressures without deforming, breaking, or chemically reacting with the workpiece. Materials like graphite or advanced ceramics are often used, but they have a finite lifespan and contribute significantly to the overall cost.

Making the Right Choice for Your Application

Selecting the right manufacturing process requires balancing performance requirements with economic and design realities.

- If your primary focus is maximum performance and reliability: Hot pressing is the superior choice for creating dense, void-free components where failure is not an option.

- If your primary focus is high-volume production of simple parts: Consider alternative methods like conventional press-and-sinter or metal injection molding, which offer faster cycle times and lower per-part costs.

- If your primary focus is complex geometries with high performance: You might investigate hot isostatic pressing (HIP), which applies pressure from all directions and can consolidate more intricate shapes.

By understanding the fundamental link between process, density, and performance, you can confidently select hot pressing for applications that demand the highest levels of material integrity.

Summary Table:

| Key Aspect | Details |

|---|---|

| Process | Simultaneous application of high temperature and uniaxial pressure |

| Key Benefits | Near-perfect density, enhanced mechanical strength, superior dimensional accuracy, uniform microstructure |

| Ideal Applications | Aerospace (e.g., turbine blades), automotive (e.g., brake pads), defense, medical |

| Limitations | Slower cycle times, higher costs, geometric constraints, die material challenges |

Need high-performance furnace solutions for hot pressing or other critical applications? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet the unique experimental requirements of industries like aerospace and automotive. Contact us today to enhance your lab's efficiency and material integrity!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What is a vacuum hot press furnace? Unlock Superior Material Performance