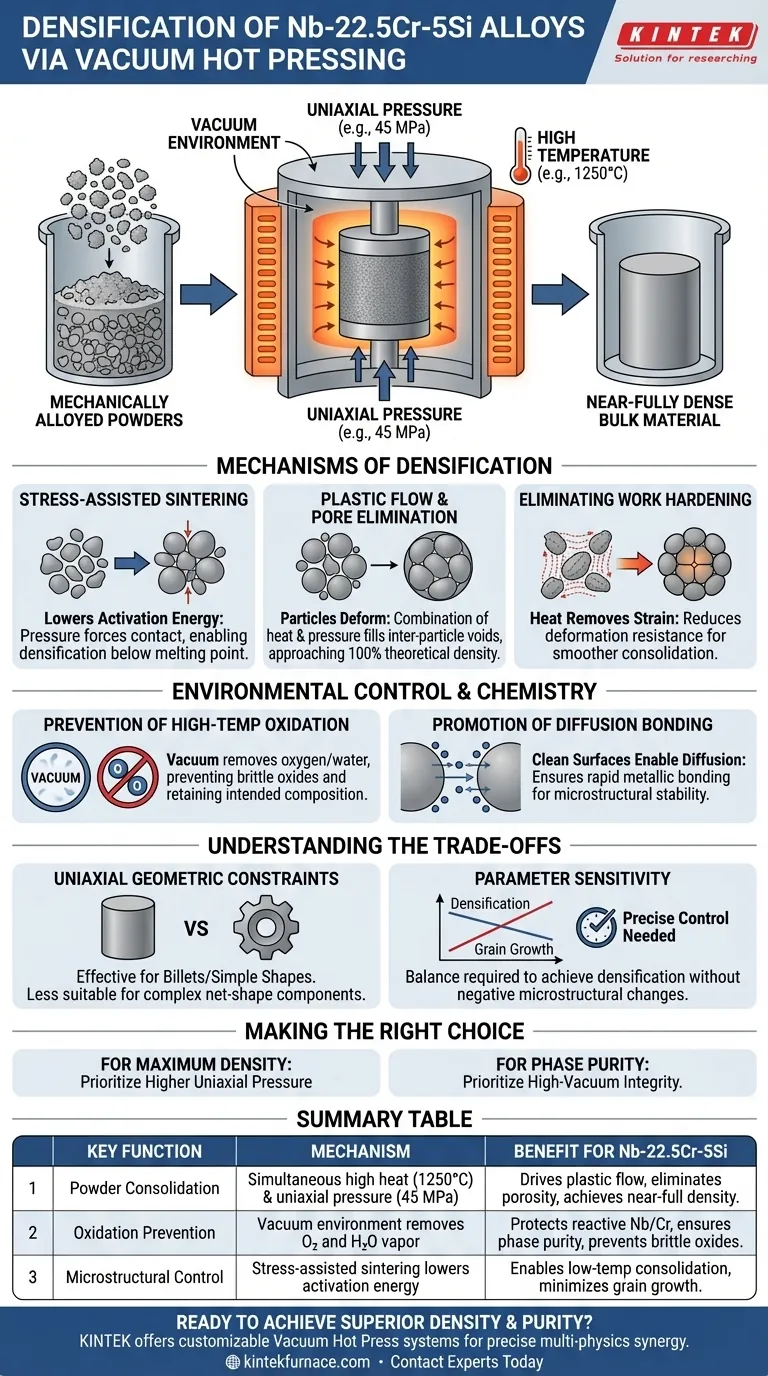

The primary function of a vacuum hot press furnace in processing Nb-22.5Cr-5Si alloys is to consolidate mechanically alloyed powders into a near-fully dense bulk material. By simultaneously applying high temperature (e.g., 1250°C) and uniaxial mechanical pressure (e.g., 45 MPa) within a vacuum, the system drives atomic diffusion and plastic flow to eliminate porosity. Crucially, the vacuum environment protects the reactive alloy components from high-temperature oxidation during this process.

Core Takeaway: Vacuum hot pressing utilizes stress-assisted sintering to lower the activation energy required for densification. It allows refractory alloys to achieve near-theoretical density at temperatures below their melting points while maintaining chemical purity.

Mechanisms of Densification

Stress-Assisted Sintering

The application of continuous uniaxial pressure fundamentally alters the sintering physics. This "stress-assisted" mechanism significantly reduces the activation energy required for the material to densify.

By applying pressure (such as 45 MPa), the furnace forces particles into physical contact. This mechanical force is far more effective than heat alone, driving the material to reach high densities even at temperatures below the alloy's melting point.

Plastic Flow and Pore Elimination

The central physical goal of the furnace is the elimination of inter-particle porosity. The combination of heat and pressure causes the powder particles to undergo plastic deformation.

As the particles deform, they fill the voids between them. This mechanism allows the physical density of the final product to approach 100% of its theoretical value, creating a solid, void-free billet from loose powder.

Eliminating Work Hardening

Mechanically alloyed powders often contain significant internal strain and work hardening. The heated environment of the press effectively eliminates this elastic strain.

This thermal treatment reduces the deformation resistance of the powder. Consequently, the material yields more easily under the applied pressure, facilitating smoother consolidation.

Environmental Control and Chemistry

Prevention of High-Temperature Oxidation

Niobium (Nb) and other refractory elements have a high affinity for oxygen, especially at elevated temperatures. Processing these materials in air would result in the formation of brittle oxides.

The vacuum environment removes oxygen and water vapor from the chamber. This ensures that the material retains its intended chemical composition and prevents the degradation of mechanical properties associated with oxide contamination.

Promotion of Diffusion Bonding

For the alloy to act as a single unit, the individual powder particles must chemically bond. The furnace environment promotes atomic diffusion across particle boundaries.

Because the vacuum ensures particle surfaces are clean and oxide-free, metallic bonding occurs rapidly. This diffusion is essential for the microstructural stability of the Nb-22.5Cr-5Si alloy.

Understanding the Trade-offs

Uniaxial Geometric Constraints

The pressure applied in these furnaces is uniaxial (from one direction). While effective for creating billets or simple shapes, this method is less suitable for creating complex, net-shape components compared to isostatic pressing methods.

Parameter Sensitivity

Achieving the "multi-physics synergy" of temperature, pressure, and vacuum requires precise control. For example, while heat aids diffusion, excessive temperatures held for long periods (e.g., 100 hours) can lead to unwanted grain growth.

Operators must balance the need for densification against the risk of altering the microstructure negatively. The process relies on finding the exact window where plastic flow occurs without compromising phase stability.

Making the Right Choice for Your Goal

To optimize the processing of Nb-22.5Cr-5Si alloys, align your furnace parameters with your specific material objectives:

- If your primary focus is Maximum Density: Prioritize higher uniaxial pressures (e.g., 45 MPa) to maximize plastic flow and eliminate internal pore defects mechanically.

- If your primary focus is Phase Purity: Prioritize high-vacuum integrity to prevent oxidation and ensure metallic bonding without brittle oxide formation.

Summary: The vacuum hot press furnace acts as a critical enabler for refractory alloys, substituting thermal energy with mechanical force to achieve fully dense, oxidation-free materials that pressureless sintering cannot produce.

Summary Table:

| Key Function | Mechanism | Benefit for Nb-22.5Cr-5Si Alloys |

|---|---|---|

| Powder Consolidation | Simultaneous high heat (e.g., 1250°C) and uniaxial pressure (e.g., 45 MPa) | Drives plastic flow to eliminate porosity, achieving near-full density |

| Oxidation Prevention | Vacuum environment removes oxygen and water vapor | Protects reactive niobium and chromium, ensuring phase purity and preventing brittle oxides |

| Microstructural Control | Stress-assisted sintering lowers activation energy for densification | Enables consolidation below melting point, minimizing unwanted grain growth |

Ready to achieve superior density and purity for your advanced refractory alloys?

Our vacuum hot press furnaces are engineered to deliver the precise multi-physics synergy of temperature, pressure, and vacuum integrity required for materials like Nb-22.5Cr-5Si. Backed by expert R&D and manufacturing, KINTEK offers a range of customizable lab high-temperature furnaces, including Vacuum Hot Press systems, to meet your unique research and production goals.

Contact our experts today to discuss how we can optimize your densification process!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What are the primary application fields for box furnaces and vacuum furnaces? Choose the Right Furnace for Your Process

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance