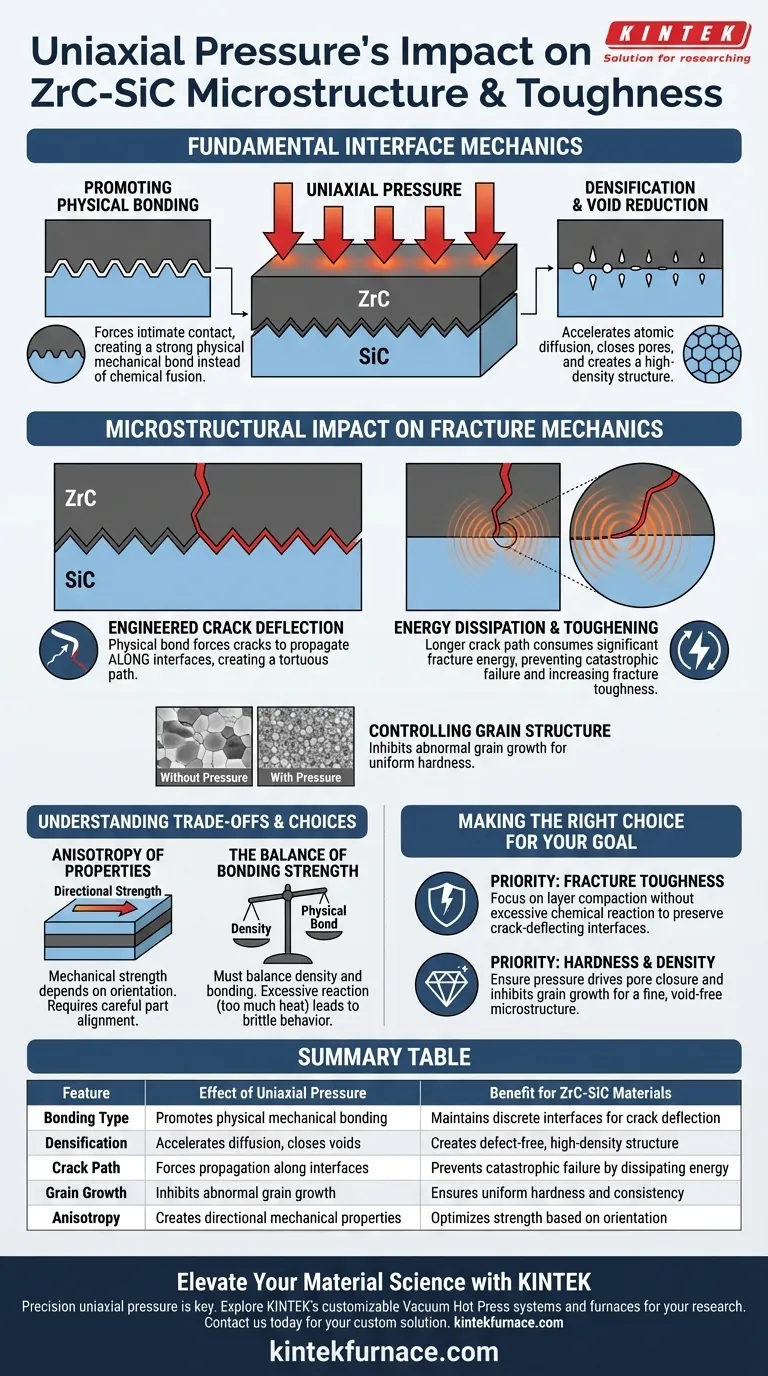

Uniaxial pressure applied by a vacuum hot press furnace fundamentally dictates the interface mechanics of ZrC-SiC layered materials. By forcing the layers into intimate contact, the pressure promotes a strong physical mechanical bond while minimizing the formation of complex chemical reaction phases. This specific microstructural arrangement is essential for creating a toughened material capable of deflecting cracks during stress.

Core Takeaway The continuous pressure does not just densify the material; it engineers a specific fracture behavior. By favoring physical bonding between layers over chemical fusion, the process creates pathways for crack deflection, which consumes fracture energy and significantly prevents catastrophic failure.

The Mechanism of Interlayer Bonding

Promoting Physical Contact Over Chemical Reaction

The primary function of the uniaxial pressure is to force the distinct layers of ZrC and SiC into close, continuous contact.

Instead of facilitating a deep chemical reaction that fuses the layers into a single brittle block, the pressure encourages a physical mechanical bond. This distinction is critical for maintaining the discrete layered architecture necessary for the material's toughening mechanisms.

Densification and Void Reduction

The application of constant axial pressure acts as an auxiliary driving force for atomic diffusion during the sintering holding phase.

This pressure facilitates the closure of pores and the filling of voids between the distinct layers. The result is a highly dense structure where the layers are tightly packed, reducing defects that could serve as initiation points for failure.

Microstructural Impact on Fracture Mechanics

Engineered Crack Deflection

The physical nature of the bond created by uniaxial pressure dictates how the material behaves when it cracks.

Because the layers are mechanically bonded rather than chemically fused, cracks are forced to propagate along the interface of the layers rather than cutting straight through them. This deflection creates a tortuous crack path, preventing immediate, catastrophic failure of the component.

Energy Dissipation and Toughening

The process of deflecting cracks along the layered interfaces consumes a significant amount of fracture energy.

By forcing the crack to travel a longer distance and change direction, the microstructure effectively absorbs energy. This results in a material with significantly improved fracture toughness, making it far more resilient than a monolithic ceramic composed of the same materials.

Controlling Grain Structure

Precise pressure application inhibits abnormal grain growth during the high-temperature sintering phase.

This ensures the microstructure remains fine and uniformly distributed. A consistent grain structure is vital for maintaining uniform hardness and preventing localized weak spots within the ceramic layers.

Understanding the Trade-offs

Anisotropy of Properties

It is important to recognize that uniaxial pressure creates a microstructure with directional properties.

The material will exhibit different mechanical strengths depending on whether the force is applied parallel or perpendicular to the pressed layers. While this is beneficial for crack deflection, it requires careful orientation of the final part during use.

The Balance of Bonding Strength

There is a delicate balance between achieving sufficient density and maintaining the desired physical bond.

If the bonding becomes too chemically reactive (often due to excessive temperature rather than pressure), the layers may fuse too completely. This would eliminate the interface needed for crack deflection, reverting the material to a brittle behavior profile.

Making the Right Choice for Your Goal

To maximize the performance of ZrC-SiC layered materials, align your processing parameters with your specific mechanical requirements:

- If your primary focus is Fracture Toughness: Prioritize pressure parameters that ensure layer compaction without inducing excessive chemical reaction, preserving the physical interfaces required for crack deflection.

- If your primary focus is Hardness and Density: Ensure the pressure is sufficient to drive pore closure and inhibit grain growth, resulting in a fine, void-free microstructure.

Ultimately, the value of uniaxial pressure lies in its ability to turn a brittle ceramic composition into a damage-tolerant layered composite.

Summary Table:

| Feature | Effect of Uniaxial Pressure | Benefit for ZrC-SiC Materials |

|---|---|---|

| Bonding Type | Promotes physical mechanical bonding over chemical fusion | Maintains discrete interfaces for crack deflection |

| Densification | Accelerates atomic diffusion and closes voids/pores | Creates a defect-free, high-density layered structure |

| Crack Path | Forces crack propagation along layer interfaces | Prevents catastrophic failure by dissipating energy |

| Grain Growth | Inhibits abnormal grain growth during sintering | Ensures uniform hardness and structural consistency |

| Anisotropy | Creates directional mechanical properties | Optimizes strength based on specific stress orientation |

Elevate Your Material Science with KINTEK

Precision in uniaxial pressure is the key to transforming brittle ceramics into high-performance composites. Backed by expert R&D and manufacturing, KINTEK offers advanced Vacuum Hot Press systems, Muffle, Tube, Rotary, and CVD furnaces, all fully customizable to meet your unique research and production needs.

Whether you are engineering next-generation ZrC-SiC layers or optimizing densification for advanced alloys, our high-temperature systems provide the control and reliability required for breakthrough results. Contact us today to find your custom solution.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How to maintain a vacuum machine? Ensure long-term reliability and peak performance

- What is the necessity of maintaining a high vacuum environment during AZ31 sintering? Prevent Oxidation and Porosity

- What is the function of Molybdenum Disulfide (MoS2) coating on molds during vacuum hot press sintering? Protect Your Samples and Molds from Damage

- What are the primary advantages of industrial SPS vs. vacuum hot-pressing for Ti-6Al-4V? Achieve Superior Microstructure

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What are the primary applications of vacuum press technology in metalworking? Achieve Precision in Aerospace, Automotive, and Electronics

- What are the benefits of the high vacuum environment in a vacuum hot pressing sintering furnace? Gain Maximum Density

- What are the advantages of SPS for BCZY712 electrolytes? Achieve 98% Density and Superior Proton Conductivity