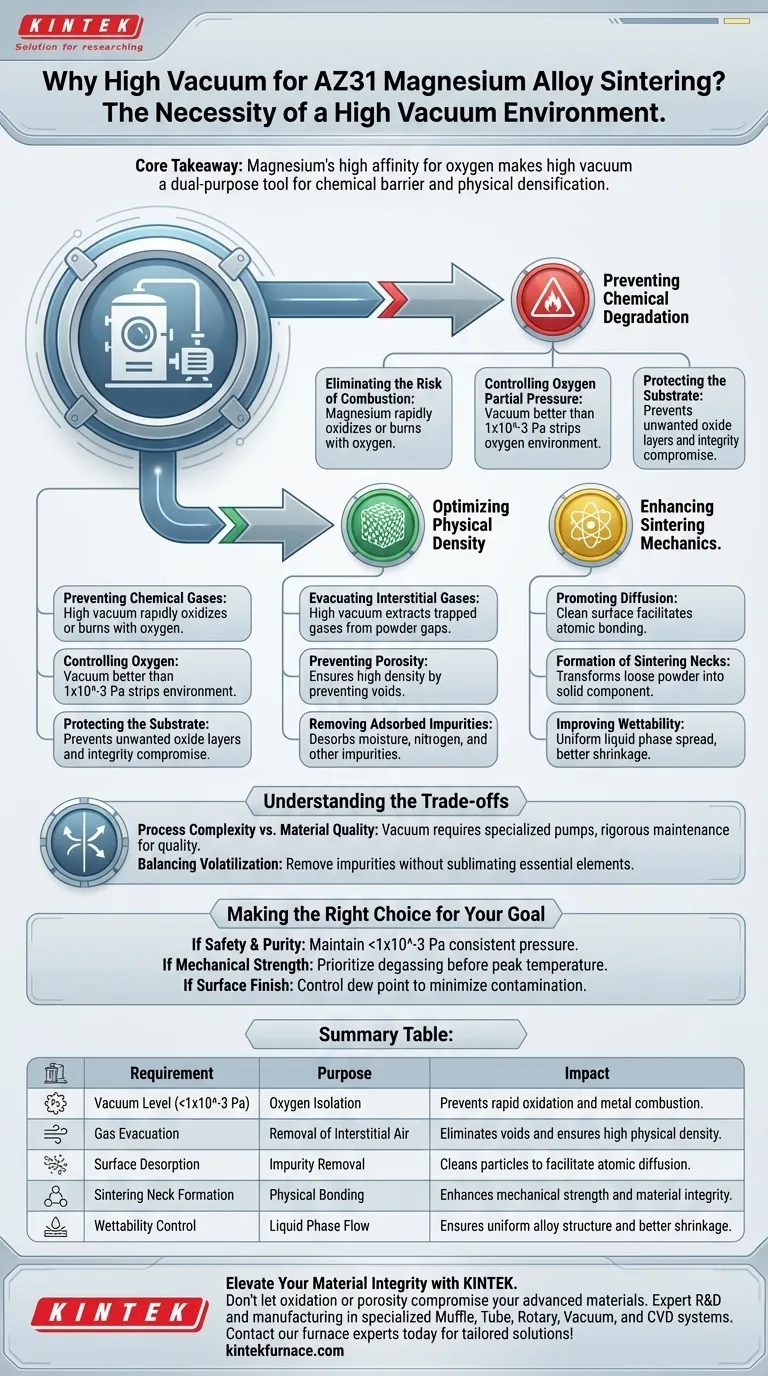

The primary necessity of a high vacuum environment when sintering AZ31 magnesium alloy is to counteract the metal's extreme chemical reactivity. Because magnesium is prone to rapid oxidation and combustion, a vacuum (specifically better than 1x10^-3 Pa) is required to isolate oxygen and evacuate trapped gases, ensuring the material remains safe, pure, and structurally dense.

Core Takeaway Magnesium’s high affinity for oxygen transforms the sintering process from a manufacturing step into a potential safety hazard and quality failure. A high vacuum acts as a dual-purpose tool: it is a chemical barrier that prevents the powder from burning, and a physical mechanism that forces porosity out of the final product.

Preventing Chemical Degradation

Eliminating the Risk of Combustion

Magnesium is a chemically active metal. When exposed to high temperatures in the presence of oxygen, it does not merely degrade; it can oxidize rapidly or even burn.

Controlling Oxygen Partial Pressure

To process AZ31 safely, you must lower the oxygen partial pressure significantly. By maintaining a vacuum level better than 1x10^-3 Pa, you effectively strip the environment of the oxygen required for these volatile reactions to occur.

Protecting the Substrate

This isolation is not just for the powder. The vacuum environment protects the entire matrix from oxidation, preventing the formation of unwanted oxide layers that would compromise the alloy's integrity.

Optimizing Physical Density

Evacuating Interstitial Gases

Metal powders naturally contain gaps (interstices) filled with atmospheric gas. If you sinter without a vacuum, these gases become trapped inside the melting material.

Preventing Porosity

A high vacuum mechanically extracts these gases from the powder gaps. This removal is critical for preventing voids and porosity, ensuring the final sintered body achieves high density.

Removing Adsorbed Impurities

Beyond the air in the gaps, gases and moisture are often adsorbed onto the surface of the powder particles. Vacuum sintering effectively desorbs these impurities, including water vapor and nitrogen.

Enhancing Sintering Mechanics

Promoting Diffusion

Sintering relies on atomic diffusion to bond particles together. Surface oxides and adsorbed gases act as barriers to this diffusion.

Formation of Sintering Necks

By creating a "clean" surface environment, the vacuum facilitates the formation of sintering necks between particles. This is the physical mechanism that transforms loose powder into a solid, cohesive component.

Improving Wettability

In liquid phase sintering, a vacuum improves wettability. This allows the liquid phase to spread more evenly, leading to better shrinkage and a more uniform alloy structure.

Understanding the Trade-offs

Process Complexity vs. Material Quality

While vacuum sintering is essential for quality, it introduces significant equipment complexity compared to atmospheric sintering. Achieving and maintaining a vacuum of 1x10^-3 Pa requires specialized pumps and rigorous seal maintenance.

Balancing Volatilization

While the vacuum removes impurities, you must exercise control over the process parameters. The goal is to remove harmful elements (like volatile impurities) without causing the sublimation of essential alloying elements due to excessive vacuum at high temperatures.

Making the Right Choice for Your Goal

To ensure the success of your AZ31 sintering project, consider these specific operational priorities:

- If your primary focus is Safety and Purity: Ensure your vacuum system can consistently maintain a pressure better than 1x10^-3 Pa to completely rule out oxidation and combustion risks.

- If your primary focus is Mechanical Strength: Prioritize the "degassing" phase of the vacuum cycle to ensure all adsorbed gases are removed before peak temperature, maximizing the density of the sintering necks.

- If your primary focus is Surface Finish: Utilize the vacuum to control the dew point (dryness) of the environment, minimizing surface contamination from water vapor.

Treat the vacuum not just as an empty space, but as an active tool that defines the chemical and physical success of your magnesium alloy.

Summary Table:

| Requirement | Purpose | Impact on AZ31 Alloy |

|---|---|---|

| Vacuum Level (<1x10^-3 Pa) | Oxygen Isolation | Prevents rapid oxidation and metal combustion. |

| Gas Evacuation | Removal of Interstitial Air | Eliminates voids and ensures high physical density. |

| Surface Desorption | Impurity Removal | Cleans particles to facilitate atomic diffusion. |

| Sintering Neck Formation | Physical Bonding | Enhances mechanical strength and material integrity. |

| Wettability Control | Liquid Phase Flow | Ensures uniform alloy structure and better shrinkage. |

Elevate Your Material Integrity with KINTEK

Don't let oxidation or porosity compromise your advanced materials. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically designed to handle the rigorous demands of reactive alloys like magnesium.

Whether you need precise vacuum control or a fully customizable high-temperature furnace, our team is ready to engineer a solution tailored to your unique research or production needs.

Ready to achieve superior sintering results?

Contact our furnace experts today!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What advantages does vacuum press technology offer in metal shaping processes? Achieve Precision and Efficiency in Metal Forming

- What are the mechanical property advantages of AlxCoCrFeNi HEAs via VHPS vs Arc Melting? Unlock Superior Hardness

- What is the primary function of the vacuum environment in a vacuum hot press furnace during the sintering of graphite flake/copper composites? Ensure High-Performance Thermal Conductivity

- Why is a vacuum hot press furnace required for sintering CNT-Al composites? Optimize Density and Interface Bonding

- What is hot pressing sintering and how does vacuum hot pressing sintering improve the process? Achieve Superior Material Density and Purity

- What physical conditions are provided by the heating plate and high-voltage DC power supply? Mastery of Anodic Bonding

- Why is a high vacuum environment crucial when preparing copper-carbon nanotube composites in a vacuum hot press furnace? Achieve Superior Composite Integrity

- How does tailored heat and pressure control benefit hot pressing? Achieve Superior Material Density and Strength