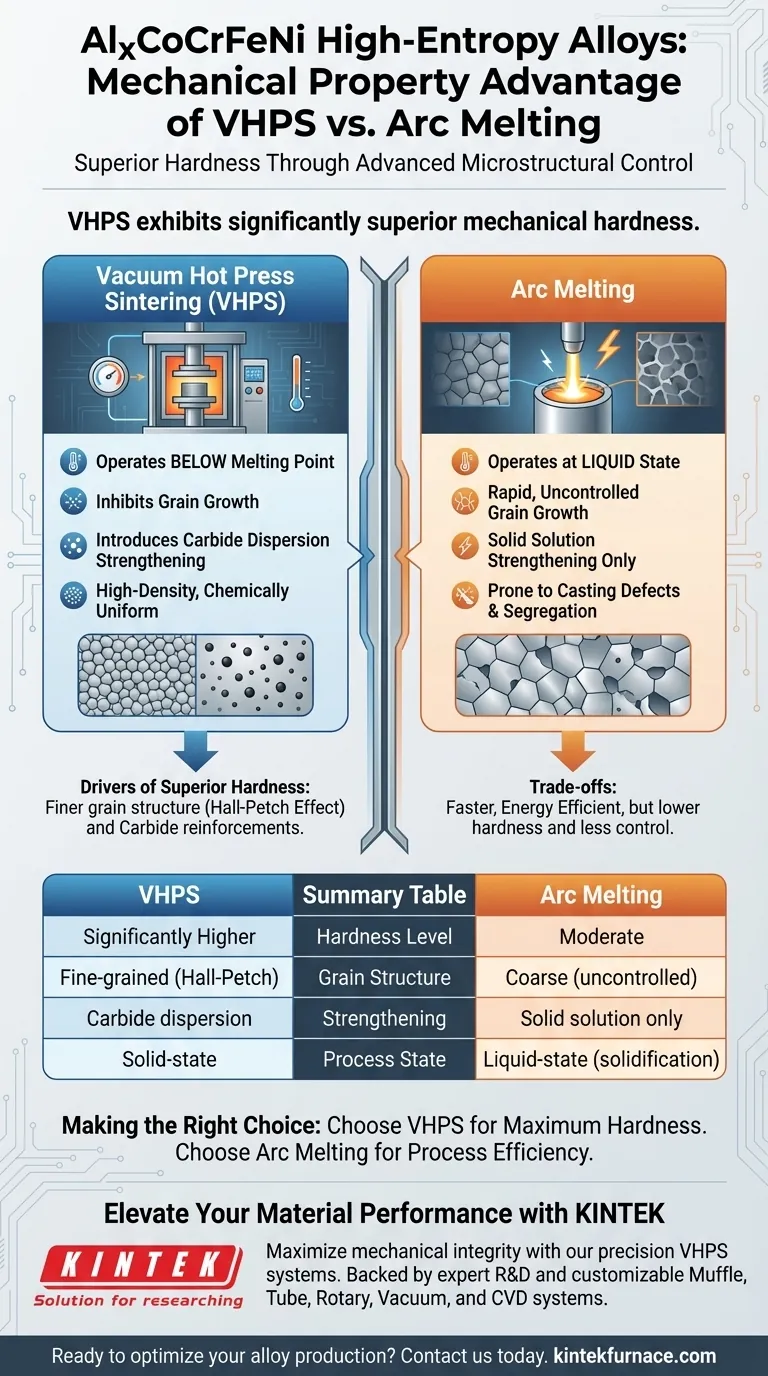

AlxCoCrFeNi high-entropy alloys prepared via Vacuum Hot Press Sintering (VHPS) exhibit significantly superior mechanical hardness compared to identical alloys produced by arc melting. This advantage is derived from the distinct microstructural controls inherent to the VHPS process, specifically the inhibition of grain growth and the introduction of strengthening phases.

While arc melting offers energy efficiency and versatility, VHPS is the superior method for maximizing mechanical performance. It achieves higher hardness by maintaining a fine-grained structure and introducing carbide dispersion strengthening, overcoming the segregation issues common in melt-based processing.

The Drivers of Superior Hardness

To understand why VHPS yields harder materials, we must look at how the processing environment alters the alloy's internal structure.

Inhibiting Grain Growth

The VHPS process operates at temperatures below the melting point of the alloy. By avoiding the liquid state, the process prevents the rapid and uncontrolled grain growth that typically occurs during the solidification phase of arc melting.

This results in a finer grain structure. According to the Hall-Petch relationship, smaller grains significantly increase a material's yield strength and hardness by impeding dislocation movement.

Dispersion Strengthening

A unique advantage of the VHPS method is the introduction of carbon elements into the alloy matrix.

These elements react to form carbides, which serve as dispersion-strengthening phases. These hard particles act as reinforcements distributed throughout the alloy, providing resistance to deformation that arc-melted samples simply do not possess.

Eliminating Macroscopic Defects

Arc melting involves chaotic liquid states that can lead to compositional non-uniformity and casting defects.

In contrast, VHPS utilizes axial pressure combined with a vacuum environment to promote particle rearrangement and plastic deformation. This creates a high-density bulk material that is chemically uniform and free from the segregation often found in arc-melted counterparts.

Understanding the Trade-offs

While VHPS produces superior mechanical properties for this specific alloy, it is essential to recognize where arc melting fits into the engineering landscape.

Efficiency vs. Performance

Arc melting is prized for its energy efficiency and speed. Because it uses electricity directly to melt material, it is often faster and suitable for processing refractory metals with extremely high melting points.

Complexity of Processing

VHPS is a solid-state sintering process. It requires precise control over pressure and temperature over longer durations to achieve full density.

Arc melting is generally more self-contained and compact, offering a more straightforward route for applications where maximum hardness is not the critical requirement.

Making the Right Choice for Your Goal

Selecting between these two methods depends entirely on whether your priority is mechanical performance or processing efficiency.

- If your primary focus is Maximum Hardness: Choose VHPS, as the fine-grained microstructure and carbide dispersion strengthening provide superior mechanical reinforcement.

- If your primary focus is Process Efficiency: Choose Arc Melting, which offers a faster, energy-efficient method for general alloy production where extreme hardness is less critical.

Ultimately, for high-performance AlxCoCrFeNi applications, VHPS provides the structural integrity and strength that arc melting cannot match.

Summary Table:

| Feature | Vacuum Hot Press Sintering (VHPS) | Arc Melting |

|---|---|---|

| Hardness Level | Significantly Higher | Moderate |

| Grain Structure | Fine-grained (Hall-Petch effect) | Coarse (uncontrolled growth) |

| Strengthening | Carbide dispersion strengthening | Solid solution only |

| Material Density | High-density via axial pressure | Prone to casting defects |

| Process State | Solid-state (below melting point) | Liquid-state (solidification) |

Elevate Your Material Performance with KINTEK

Maximize the mechanical integrity of your high-entropy alloys with precision thermal processing. KINTEK provides industry-leading Vacuum Hot Press Sintering (VHPS) systems designed to inhibit grain growth and ensure chemical uniformity in advanced materials like AlxCoCrFeNi.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or industrial needs. Whether you are aiming for maximum hardness or specialized microstructure control, our engineering team is ready to support your success.

Ready to optimize your alloy production? Contact us today to find your custom furnace solution.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the mechanical pressure of a Vacuum Hot Press Furnace improve composite density? Elevate Performance Today

- How does hot-press sintering contribute to manufacturing high-density Ta-Al-C MAX phase ceramics? Optimize Consolidation

- What are the technical advantages of Spark Plasma Sintering (SPS) systems? Faster Densification and Superior Strength

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What is the core function of a flat tablet press in CSP? Achieve High-Pressure Densification for CaF2 Ceramics

- What is the function of a vacuum hot pressing furnace? Precision Diffusion Bonding for 321H Stainless Steel

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What is the core function of a vacuum hot press sintering furnace? Unlock High-Performance TiCN Composite Synthesis