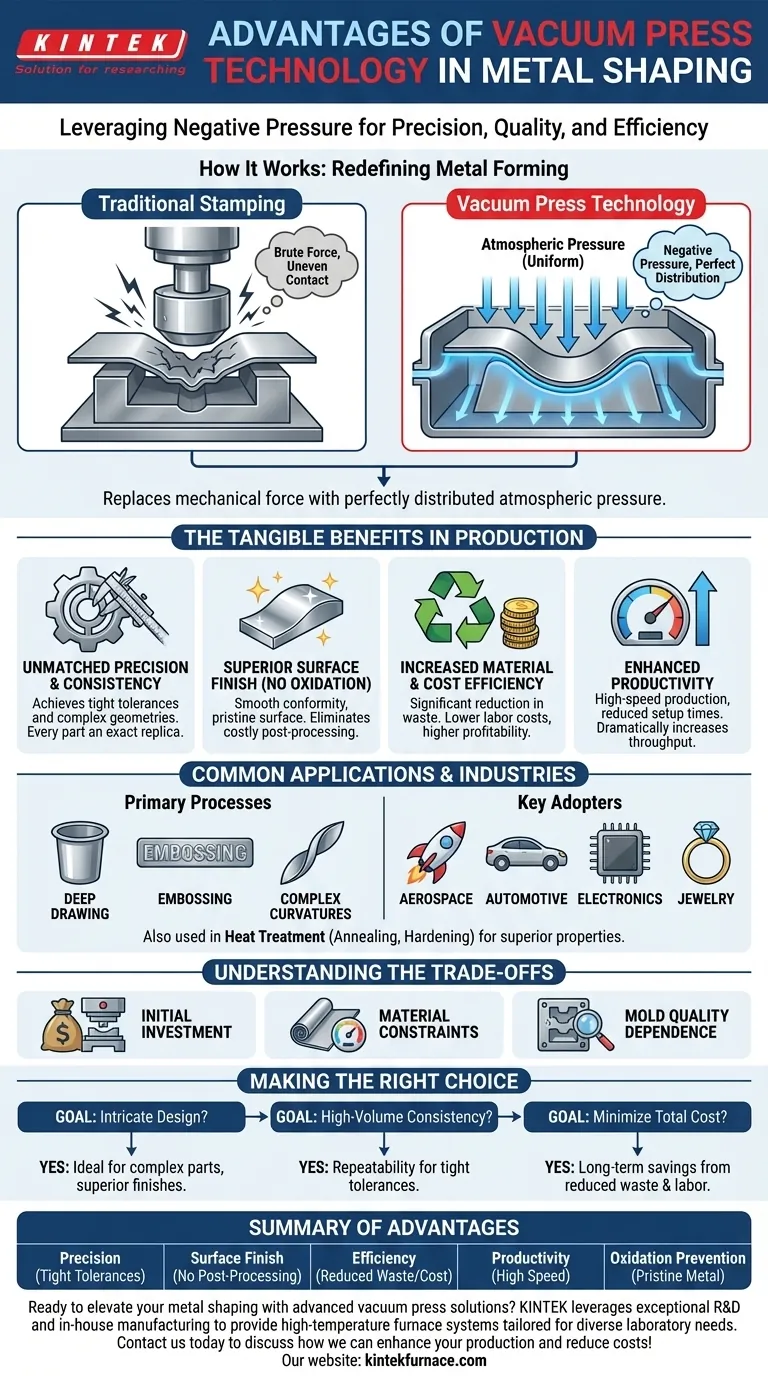

In metal shaping, vacuum press technology offers a distinct set of advantages centered on precision, quality, and operational efficiency. By leveraging negative pressure instead of mechanical force, it allows for the creation of highly detailed and consistent parts with superior surface finishes, all while minimizing material waste and the need for secondary processing.

The core problem in traditional metal shaping is the difficulty of achieving perfect, uniform contact between the metal and the mold. Vacuum press technology solves this by using atmospheric pressure as a powerful, perfectly distributed clamping force, pulling the material into every detail of a mold with unparalleled accuracy.

How Vacuum Press Technology Redefines Metal Forming

At its heart, the process is ingeniously simple. It replaces brute mechanical force with the uniform, invisible force of a vacuum.

The Principle of Negative Pressure

A vacuum press machine works by placing a metal sheet over a mold and then removing the air from the space between them. This creates a pressure differential, where the atmospheric pressure outside pushes the metal down, forcing it to conform perfectly to the mold's shape.

This method of using vacuum suction is fundamentally different from traditional stamping, which relies on a die to mechanically push the metal into a desired form.

Achieving Uniform Pressure Distribution

The greatest strength of this technique is its ability to apply perfectly uniform pressure across the entire surface of the metal sheet.

Unlike a mechanical press that has specific contact points, the vacuum ensures every square millimeter of the material is drawn to the mold with equal force. This eliminates weak spots and inconsistencies.

Eliminating Atmospheric Contamination

By removing air from the forming environment, the process inherently prevents oxidation and other surface contamination that can occur when heating and shaping metal.

This results in a pristine material surface, preserving the purity and integrity of the metal, which is especially critical for high-performance alloys used in demanding industries.

The Tangible Benefits in Production

The unique mechanism of vacuum forming translates directly into measurable improvements on the manufacturing floor.

Unmatched Precision and Consistency

The uniform pressure ensures that every part produced is an exact replica of the mold. This allows for the consistent achievement of tight tolerances and complex geometries that are difficult or impossible with other methods.

Superior Surface Finish

Because the metal conforms smoothly to the mold without the harsh impact of a die, the resulting surface finish is excellent. This drastically reduces or even eliminates the need for costly and time-consuming post-processing steps like polishing or grinding.

Increased Material and Cost Efficiency

The precision of vacuum forming leads to a significant reduction in material waste from rejected parts. Furthermore, minimizing the need for secondary finishing operations directly lowers labor costs and improves overall profitability.

Enhanced Productivity

Modern vacuum press systems are designed for high-speed production. Combined with reduced setup times compared to complex mechanical presses, this technology can dramatically increase manufacturing throughput.

Common Applications and Industries

Vacuum press technology is not a niche solution; it is a cornerstone of modern manufacturing in several key sectors.

Primary Forming Processes

The technology is exceptionally well-suited for processes like deep drawing, embossing, and forming parts with complex curvatures.

Key Industry Adopters

Industries that rely on high-precision metal components are the primary beneficiaries. This includes aerospace, automotive, consumer electronics, and even jewelry manufacturing, where intricate designs and flawless finishes are paramount.

Beyond Forming: Heat Treatment

The principle of using a vacuum to protect metal is also applied in continuous vacuum furnaces. In processes like annealing and hardening, the vacuum environment ensures uniform heating and prevents oxidation, resulting in parts with higher strength and superior metallurgical properties.

Understanding the Trade-offs

While powerful, vacuum press technology is not a universal solution. A clear-eyed view of its limitations is essential for proper application.

Initial Equipment Investment

The machinery required for vacuum forming, including the press and high-capacity vacuum pumps, represents a significant capital investment compared to some simpler mechanical presses.

Material Constraints

This process works best with metal in sheet form and may have practical limitations on the thickness and type of material that can be effectively formed. Extremely thick or less malleable metals may require other methods.

Dependence on Mold Quality

The final product is only as good as the mold. Creating high-quality, durable molds capable of withstanding forming cycles can be a complex and expensive process in itself. The design and engineering of the mold are critical to success.

Making the Right Choice for Your Application

To determine if vacuum press technology is the right fit, align its strengths with your primary production goals.

- If your primary focus is intricate design and flawless quality: This technology is unmatched for producing complex parts with superior surface finishes, making it ideal for aerospace, medical, or high-end consumer goods.

- If your primary focus is high-volume consistency: The repeatability and speed of vacuum pressing provide a significant advantage for automotive or electronics components where tight tolerances must be maintained across millions of units.

- If your primary focus is minimizing total cost of ownership: The reduction in material waste, rejected parts, and post-processing labor can deliver substantial long-term savings that offset the initial equipment investment.

Ultimately, adopting vacuum press technology empowers manufacturers to move beyond the traditional limitations of metal forming and achieve a higher standard of quality and efficiency.

Summary Table:

| Advantage | Description |

|---|---|

| Precision and Consistency | Achieves tight tolerances and complex geometries with uniform pressure distribution. |

| Superior Surface Finish | Reduces or eliminates need for post-processing like polishing or grinding. |

| Material and Cost Efficiency | Minimizes waste and lowers labor costs by reducing secondary operations. |

| Enhanced Productivity | Enables high-speed production with reduced setup times for increased throughput. |

| Oxidation Prevention | Removes air to protect metal integrity, ideal for high-performance alloys. |

Ready to elevate your metal shaping with advanced vacuum press solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace systems, including Vacuum & Atmosphere Furnaces, tailored for diverse laboratory needs. Our deep customization capabilities ensure precise solutions for your unique requirements, helping you achieve superior precision, efficiency, and quality in processes like deep drawing and heat treatment. Contact us today to discuss how we can enhance your production and reduce costs!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- How does automation enhance the hot pressing process? Boost Precision, Efficiency, and Quality

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing

- What are the applications of hot pressing? Achieve Maximum Material Performance